loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 25, 2025 05:44

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

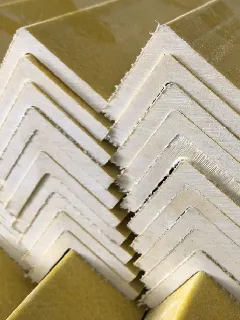

Fiber Reinforced Polymer (FRP) C Channels have revolutionized various industries with their unique combination of strength, lightweight properties, and corrosion resistance. As technology advances and demands for sustainable construction materials increase, the expertise surrounding FRP C Channels grows, offering new opportunities and challenges for engineers, architects, and builders.

Engaging firsthand experiences highlight how FRP C Channels outperform metal counterparts, particularly in seismic applications where flexibility and energy absorption are paramount. Unlike rigid steel, FRP structures are less likely to shatter or deform under stress, which is critical for infrastructure integrity in earthquake-prone areas. Many practitioners recount positive outcomes when switching to FRP materials, citing increased project speed and efficiency as notable advantages. Trust in FRP C Channels correlates strongly with continuous advancements in the field. Research and development efforts focus on enhancing the fire resistance of these composites, widening their usability scope. Additionally, recent innovations in hybrid FRP composites, which combine multiple types of fibers, are setting new benchmarks in performance standards. Regarding sustainable construction practices, FRP C Channels offer significant ecological benefits. The production process of FRP materials consumes less energy than traditional metal production, and the evolving recycling approaches ensure that leftover materials and retired components contribute less to environmental burden. This sustainable life cycle reinforces the trust in FRP C Channels as a viable component of future-proof construction solutions. In conclusion, the ascent of FRP C Channels in various sectors exemplifies their high value in modern construction and engineering. Their exceptional properties, bolstered by continual advancements in materials science, elevate them as a preferred choice for experts seeking durable, reliable, and sustainable material options. As industry leaders continue to understand and implement these materials, FRP C Channels promise to play a pivotal role in shaping the infrastructure of tomorrow.

Engaging firsthand experiences highlight how FRP C Channels outperform metal counterparts, particularly in seismic applications where flexibility and energy absorption are paramount. Unlike rigid steel, FRP structures are less likely to shatter or deform under stress, which is critical for infrastructure integrity in earthquake-prone areas. Many practitioners recount positive outcomes when switching to FRP materials, citing increased project speed and efficiency as notable advantages. Trust in FRP C Channels correlates strongly with continuous advancements in the field. Research and development efforts focus on enhancing the fire resistance of these composites, widening their usability scope. Additionally, recent innovations in hybrid FRP composites, which combine multiple types of fibers, are setting new benchmarks in performance standards. Regarding sustainable construction practices, FRP C Channels offer significant ecological benefits. The production process of FRP materials consumes less energy than traditional metal production, and the evolving recycling approaches ensure that leftover materials and retired components contribute less to environmental burden. This sustainable life cycle reinforces the trust in FRP C Channels as a viable component of future-proof construction solutions. In conclusion, the ascent of FRP C Channels in various sectors exemplifies their high value in modern construction and engineering. Their exceptional properties, bolstered by continual advancements in materials science, elevate them as a preferred choice for experts seeking durable, reliable, and sustainable material options. As industry leaders continue to understand and implement these materials, FRP C Channels promise to play a pivotal role in shaping the infrastructure of tomorrow.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025