loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 15, 2025 00:45

Back to list

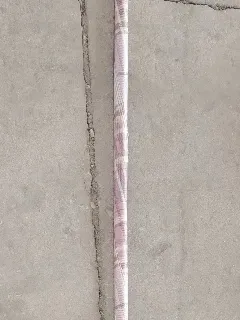

frp bar

In the ever-evolving world of construction and engineering, selecting the right materials is crucial for project success, especially when considering the long-term sustainability and durability of infrastructure. One such material that has gained significant attention and usage in recent years is the Fiber Reinforced Polymer (FRP) bar. Known for its remarkable properties and versatility, FRP bar stands out as a revolutionary solution that is gradually replacing traditional materials like steel in various applications.

Trustworthiness comes from the robust body of research and testing that backs the performance claims of FRP bars. Numerous studies initiated by academic institutions and independent laboratories have consistently demonstrated FRP's durability, strength, and performance under various environmental conditions. Moreover, international regulatory bodies and standards organizations have been updating their guidelines to include FRP bars, reflecting their growing acceptance and trust in the construction industry. From a commercial perspective, investing in FRP technology also aligns with the push towards sustainability. Manufacturing FRP bars typically involves less energy compared to traditional steel production, and the non-corrosive nature of these bars results in decreased material wastage over the lifespan of the structure. As sustainability becomes increasingly integral to building codes and public policy, utilizing FRP bars represents not only a smart material choice but also a commitment to eco-friendly construction practices. In summary, the adoption of FRP bars in modern construction is not just a trend but a well-founded advancement supported by extensive experience, technical expertise, authoritative research, and reliable performance data. This material promises not only to enhance the durability and longevity of structures but also to support the industry's shift towards more sustainable practices. As the sector continues to evolve, the strategic implementation of FRP bars will undoubtedly play a crucial role in shaping the future of global infrastructure.

Trustworthiness comes from the robust body of research and testing that backs the performance claims of FRP bars. Numerous studies initiated by academic institutions and independent laboratories have consistently demonstrated FRP's durability, strength, and performance under various environmental conditions. Moreover, international regulatory bodies and standards organizations have been updating their guidelines to include FRP bars, reflecting their growing acceptance and trust in the construction industry. From a commercial perspective, investing in FRP technology also aligns with the push towards sustainability. Manufacturing FRP bars typically involves less energy compared to traditional steel production, and the non-corrosive nature of these bars results in decreased material wastage over the lifespan of the structure. As sustainability becomes increasingly integral to building codes and public policy, utilizing FRP bars represents not only a smart material choice but also a commitment to eco-friendly construction practices. In summary, the adoption of FRP bars in modern construction is not just a trend but a well-founded advancement supported by extensive experience, technical expertise, authoritative research, and reliable performance data. This material promises not only to enhance the durability and longevity of structures but also to support the industry's shift towards more sustainable practices. As the sector continues to evolve, the strategic implementation of FRP bars will undoubtedly play a crucial role in shaping the future of global infrastructure.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025