loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable Steel Grating Solutions for Industrial Flooring Applications

The Advantages and Applications of Floor Metal Grating

In various industrial settings, floor metal grating has emerged as a critical component for enhancing safety, functionality, and efficiency. This versatile material is used to create a variety of flooring solutions, offering an impactful blend of strength, durability, and style. In this article, we will explore the benefits, applications, and considerations for using floor metal grating in different environments.

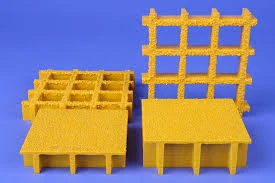

Understanding Floor Metal Grating

Floor metal grating is typically constructed from materials such as steel, aluminum, or stainless steel, designed in a grid-like pattern that allows for both structural integrity and drainage. The design of this grating provides a non-slip surface while simultaneously allowing light, air, and water to pass through, making it a popular choice in numerous applications.

Key Benefits of Floor Metal Grating

1. Durability and Strength One of the standout features of metal grating is its exceptional strength-to-weight ratio. Whether constructed from carbon steel, aluminum, or stainless steel, these gratings can bear substantial loads, making them suitable for high-traffic areas and heavy machinery environments.

2. Safety Floor metal grating is designed with safety in mind. Its slip-resistant surface reduces the risk of falls, even in wet or oily conditions. Additionally, the open design allows for quick drainage, minimizing puddling and further enhancing safety.

3. Versatility Metal grating can be used in a variety of settings, including industrial facilities, commercial buildings, and even residential applications. It is commonly found in walkways, platforms, catwalks, and in areas where equipment needs to be accessed safely.

4. Easy Maintenance Compared to other flooring options, metal grating is relatively easy to clean. The grid structure allows debris and spills to fall through, preventing the accumulation of dirt and grime that could compromise hygiene and safety.

5. Corrosion Resistance When choosing the right type of metal for grating, corrosion-resistance can be a significant advantage. Stainless steel and aluminum, for instance, offer excellent resistance to corrosion, making them suitable for outdoor or tough environments, such as wastewater treatment facilities.

Applications of Floor Metal Grating

1. Industrial Settings Factories and warehouses frequently utilize metal grating in flooring systems for loading docks, machinery access platforms, and walkways. Its ability to handle heavy loads and provide stability makes it ideal for these environments.

floor metal grating

2. Commercial Properties Retail spaces, including shopping malls and grocery stores, benefit from the aesthetic appeal and functionality of metal grating. It can be used in fixtures such as display stands or as flooring in areas that require an inviting yet durable surface.

3. Civic Infrastructure Many public buildings and infrastructure projects utilize floor metal grating for stairways, bridges, and elevated walkways. The light weight and strength of the material make it a favored choice among architects and engineers.

4. Water Treatment Plants Due to its resistance to corrosion and easy cleaning properties, metal grating is extensively used in water treatment facilities. It facilitates proper drainage while ensuring safe access to treatment equipment.

5. Residential Use Increasingly, homeowners are using metal grating for outdoor areas, such as decks, patios, and garden walkways. Its modern look adds a unique touch to landscaping projects while providing a practical surface that withstands outdoor conditions.

Considerations for Choosing Floor Metal Grating

When selecting the appropriate metal grating, several considerations should be taken into account

- Material Type Choose between carbon steel, aluminum, or stainless steel based on the specific environment and any potential exposure to corrosive elements.

- Load Bearing Requirements Assess the weight that the grating will need to support. This will influence the thickness and spacing of the grating bars.

- Surface Coating Some applications may require additional protective coatings to enhance resistance to corrosion or wear.

- Compliance with Safety Standards Ensure that the chosen flooring solution meets any pertinent safety regulations and guidelines for your specific industry.

Conclusion

Floor metal grating serves as a practical and effective solution across various industries and applications. Its combination of durability, safety, and versatility makes it an essential component in modern construction and infrastructure. Whether for industrial, commercial, or residential use, the thoughtful incorporation of metal grating can significantly enhance functionality, safety, and aesthetics, ultimately contributing to more efficient and secure environments.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025