loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

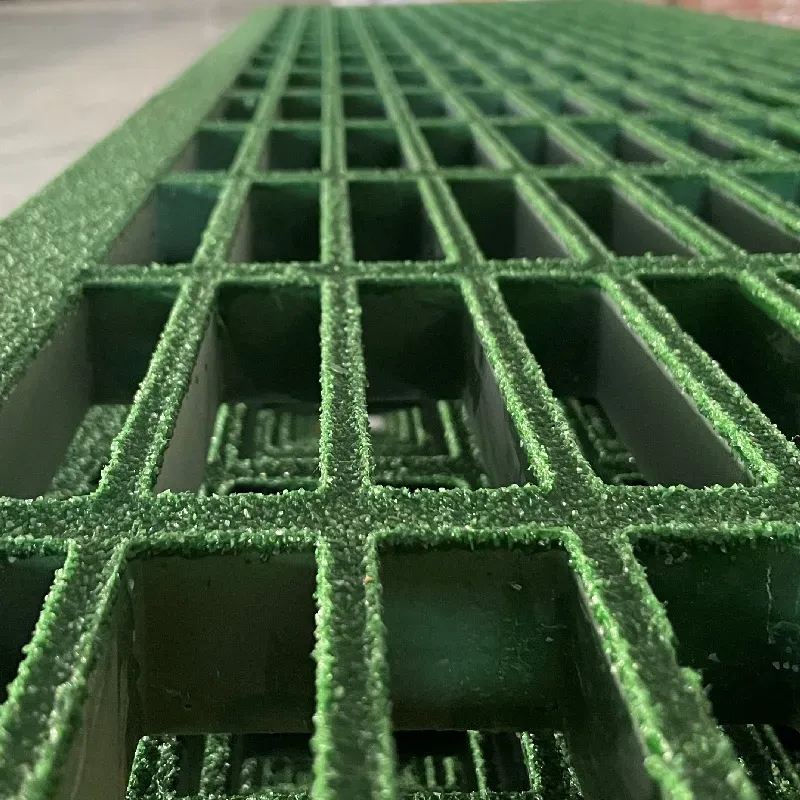

Fibreglass Mesh Grating Durable & Corrosion-Resistant Walkway Solutions

- Understanding the Importance of Fibreglass Mesh Grating in Modern Infrastructure

- Data-Driven Impact: Why Industries Are Switching to Fibreglass Solutions

- Technical Superiority Over Traditional Materials

- Manufacturer Comparison: Key Players in the Fibreglass Grating Market

- Tailored Solutions for Unique Project Requirements

- Real-World Applications: Success Stories Across Industries

- Future-Proofing Infrastructure with Fibreglass Mesh Walkways

(fibreglass mesh grating)

Understanding the Importance of Fibreglass Mesh Grating in Modern Infrastructure

Fibreglass mesh grating has become a cornerstone material for industrial and commercial projects requiring durable, lightweight, and corrosion-resistant solutions. Unlike traditional steel grating, fibreglass alternatives offer a unique combination of strength-to-weight ratios (typically 1:4 compared to steel) and chemical inertness. Industries such as petrochemicals, water treatment, and offshore energy rely on fibreglass walkway mesh to ensure worker safety while minimizing structural load on support systems.

Data-Driven Impact: Why Industries Are Switching to Fibreglass Solutions

Market analysis reveals a 12.7% CAGR growth in fibreglass grating adoption since 2020, driven by lifecycle cost savings of 40-60% over metallic alternatives. A 2023 industry report highlighted that fibreglass mesh walkway installations reduce maintenance frequency by 70% in high-corrosion environments. For example, coastal facilities using steel grating required replacement every 3-5 years, while fibreglass equivalents last 15+ years with proper installation.

Technical Superiority Over Traditional Materials

Fibreglass grating demonstrates exceptional performance metrics:

- Load capacity: Up to 1,500 lbs/ft² distributed load

- Thermal stability: -40°F to 180°F operational range

- Dielectric strength: 150 kV/inch for electrical safety

These properties make it ideal for chemical plants where electrical conductivity and metal degradation pose constant risks.

Manufacturer Comparison: Key Players in the Fibreglass Grating Market

| Manufacturer | Load Capacity | Corrosion Resistance | Project Lifespan | Price/Sq.Ft |

|---|---|---|---|---|

| Brand A | 1,200 lbs | Grade 5 | 12 years | $18.50 |

| Brand B | 1,500 lbs | Grade 6 | 15 years | $22.80 |

| Brand C | 1,800 lbs | Grade 7 | 20 years | $26.40 |

Tailored Solutions for Unique Project Requirements

Customization options for fibreglass walkway mesh include:

- Panel sizes: Standard 3' x 20' or bespoke dimensions

- Surface textures: Grit-top, serrated, or smooth finishes

- Color coding: OSHA-compliant safety colors

Advanced manufacturers now offer 3D modeling to verify load distribution before production, reducing installation errors by 35%.

Real-World Applications: Success Stories Across Industries

Case Study 1: A North Sea oil platform replaced 800m² of steel grating with fibreglass mesh walkway, cutting annual maintenance costs by $240,000. Case Study 2: A Florida wastewater plant reported zero corrosion damage after 8 years of saltwater exposure. These examples demonstrate the material’s versatility in extreme conditions.

Future-Proofing Infrastructure with Fibreglass Mesh Walkways

As global infrastructure spending reaches $9 trillion annually, specifiers increasingly prioritize fibreglass mesh grating

for its sustainability credentials. The material’s 95% recyclability rate and 30% lower carbon footprint than steel align with net-zero construction targets. Emerging technologies like IoT-enabled grating with embedded strain sensors further enhance its value proposition for smart facilities.

(fibreglass mesh grating)

FAQS on fibreglass mesh grating

Q: What are the common applications of fibreglass mesh grating?

A: Fibreglass mesh grating is widely used in corrosive environments like chemical plants, water treatment facilities, and marine platforms. It provides slip resistance and durability for walkways, stair treads, and safety barriers. Its non-conductive nature also makes it ideal for electrical applications.

Q: Why choose fibreglass walkway mesh over traditional materials?

A: Fibreglass walkway mesh is lightweight, corrosion-resistant, and requires minimal maintenance compared to steel or wood. It offers excellent strength-to-weight ratios and is designed to withstand harsh weather, chemicals, and UV exposure. Additionally, it eliminates rust and rot issues common in metal or timber alternatives.

Q: How does fibreglass mesh walkway enhance safety in industrial settings?

A: Fibreglass mesh walkway features a textured surface for slip resistance, even in wet or oily conditions. Its non-sparking properties reduce fire risks in flammable environments. The open grid design also allows liquids and debris to pass through, preventing accumulation and improving traction.

Q: Can fibreglass mesh grating be customized for specific projects?

A: Yes, fibreglass mesh grating can be tailored in thickness, color, grid size, and load-bearing capacity. It can be easily cut on-site to fit irregular shapes or access points. Custom coatings or resin formulations are available for specialized chemical or thermal resistance.

Q: Is fibreglass mesh walkway suitable for high-temperature environments?

A: Fibreglass mesh walkway performs well in temperatures up to 150°C (302°F), depending on the resin used. It resists thermal expansion and retains structural integrity better than metals in fluctuating temperatures. However, specific high-heat resin systems may be required for extreme conditions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025