loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 09, 2025 12:02

Back to list

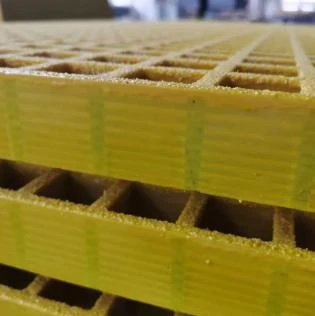

pultruded frp grating

Navigating the world of construction materials, pultruded FRP grating emerges as a superior choice for industries across the globe. This product's unique blend of strength, durability, and versatility makes it a leading option for those seeking innovative solutions in infrastructure and design. Through a blend of thorough technical insights and real-world applications, this discussion on pultruded FRP grating aims to highlight its unmatched advantages and why experts consistently choose it.

Furthermore, the customization capabilities of pultruded FRP grating set it apart from other grating systems. Sections can be tailored to specific shapes and sizes, meeting the exacting needs of diverse design requirements. This adaptability extends to color options, allowing for color coding in safety-conscious industries or aesthetics in architectural applications. This ability to customize aids in achieving project-specific goals while maintaining the high-performance standards that pultruded FRP grating inherently provides. Authoritative voices in engineering and design consistently verify the longevity and reliability of pultruded FRP grating. Its low maintenance needs endorse it as a cost-effective solution over time, removing the need for frequent repairs or replacements. Trust in this material's performance is built upon years of research and case studies that consistently validate its resilience under extensive and varied conditions. Pultruded FRP grating's multi-faceted benefits underscore its growing prominence in a range of sectors. As industries continue to innovate and demand materials that align with contemporary standards of sustainability and efficiency, pultruded FRP grating stands as a testament to modern engineering's capability to meet and exceed these expectations. Through a commitment to quality, customization, and safety, it offers a compelling solution that professionals around the world trust and utilize in their pursuit of superior construction outcomes.

Furthermore, the customization capabilities of pultruded FRP grating set it apart from other grating systems. Sections can be tailored to specific shapes and sizes, meeting the exacting needs of diverse design requirements. This adaptability extends to color options, allowing for color coding in safety-conscious industries or aesthetics in architectural applications. This ability to customize aids in achieving project-specific goals while maintaining the high-performance standards that pultruded FRP grating inherently provides. Authoritative voices in engineering and design consistently verify the longevity and reliability of pultruded FRP grating. Its low maintenance needs endorse it as a cost-effective solution over time, removing the need for frequent repairs or replacements. Trust in this material's performance is built upon years of research and case studies that consistently validate its resilience under extensive and varied conditions. Pultruded FRP grating's multi-faceted benefits underscore its growing prominence in a range of sectors. As industries continue to innovate and demand materials that align with contemporary standards of sustainability and efficiency, pultruded FRP grating stands as a testament to modern engineering's capability to meet and exceed these expectations. Through a commitment to quality, customization, and safety, it offers a compelling solution that professionals around the world trust and utilize in their pursuit of superior construction outcomes.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025