loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 20, 2025 06:06

Back to list

frp vessel for water treatment

Understanding FRP Pressure Vessel Filters A Comprehensive Guide

Trustworthiness in an FRP pressure vessel is augmented by rigorous testing and certification standards, ensuring compliance with international benchmarks such as ASME and NSF. These certifications affirm the vessels’ performance, rooting customer confidence in their consistent ability to deliver superior filtration capabilities. Such recognized standards align FRP pressure vessels with a global commitment to quality and reliability. In addition, the operational reliability is enhanced by their non-reactive nature, which ensures that eroding elements do not compromise the integrity of the stored materials. This is a critical consideration in applications involving sensitive fluids or chemicals where contamination risks need to be managed meticulously. Thus, FRP pressure vessels serve not only as a mechanical filtration solution but as a strategic component in safeguarding fluid purity. Experience-driven insights have continually refined the fabrication of FRP pressure vessels, leading to advancements in design and production processes. These processes incorporate state-of-the-art techniques such as filament winding, which not only ensure uniformity in structure but also permit customization to meet specific volumetric and pressure requirements. This precision in fabrication is a hallmark of the seasoned manufacturers who uphold a commitment to tailor solutions without compromising on quality. As a testament to their expertise, manufacturers often provide comprehensive after-sales support, including technical consultation and maintenance services. Such client-centered offerings are integral to establishing long-term trust and ensuring that the FRP pressure vessels operate at peak performance throughout their lifecycle. In conclusion, FRP pressure vessel filters embody a revolutionary leap in filtration technology, blending expert engineering with authoritative quality and trustworthy performance. For industry professionals seeking a sustainable, adaptable, and reliable filtration solution, these vessels present an unmatched option that combines technical innovation with real-world application success. Whether applied in industrial, commercial, or residential settings, the implementation of FRP pressure vessels stands as a strategic decision that aligns with modern fluid management needs, supporting both operational goals and environmental stewardship.

Trustworthiness in an FRP pressure vessel is augmented by rigorous testing and certification standards, ensuring compliance with international benchmarks such as ASME and NSF. These certifications affirm the vessels’ performance, rooting customer confidence in their consistent ability to deliver superior filtration capabilities. Such recognized standards align FRP pressure vessels with a global commitment to quality and reliability. In addition, the operational reliability is enhanced by their non-reactive nature, which ensures that eroding elements do not compromise the integrity of the stored materials. This is a critical consideration in applications involving sensitive fluids or chemicals where contamination risks need to be managed meticulously. Thus, FRP pressure vessels serve not only as a mechanical filtration solution but as a strategic component in safeguarding fluid purity. Experience-driven insights have continually refined the fabrication of FRP pressure vessels, leading to advancements in design and production processes. These processes incorporate state-of-the-art techniques such as filament winding, which not only ensure uniformity in structure but also permit customization to meet specific volumetric and pressure requirements. This precision in fabrication is a hallmark of the seasoned manufacturers who uphold a commitment to tailor solutions without compromising on quality. As a testament to their expertise, manufacturers often provide comprehensive after-sales support, including technical consultation and maintenance services. Such client-centered offerings are integral to establishing long-term trust and ensuring that the FRP pressure vessels operate at peak performance throughout their lifecycle. In conclusion, FRP pressure vessel filters embody a revolutionary leap in filtration technology, blending expert engineering with authoritative quality and trustworthy performance. For industry professionals seeking a sustainable, adaptable, and reliable filtration solution, these vessels present an unmatched option that combines technical innovation with real-world application success. Whether applied in industrial, commercial, or residential settings, the implementation of FRP pressure vessels stands as a strategic decision that aligns with modern fluid management needs, supporting both operational goals and environmental stewardship.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

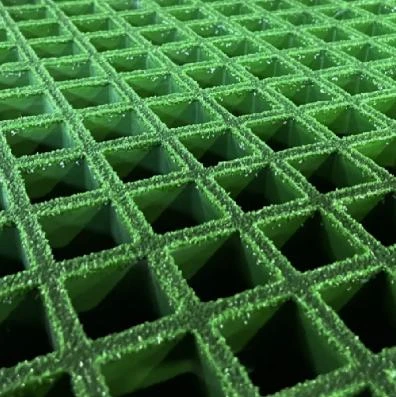

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025