- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

More Language

Untranslated

Feb . 19, 2025 05:41

Back to list

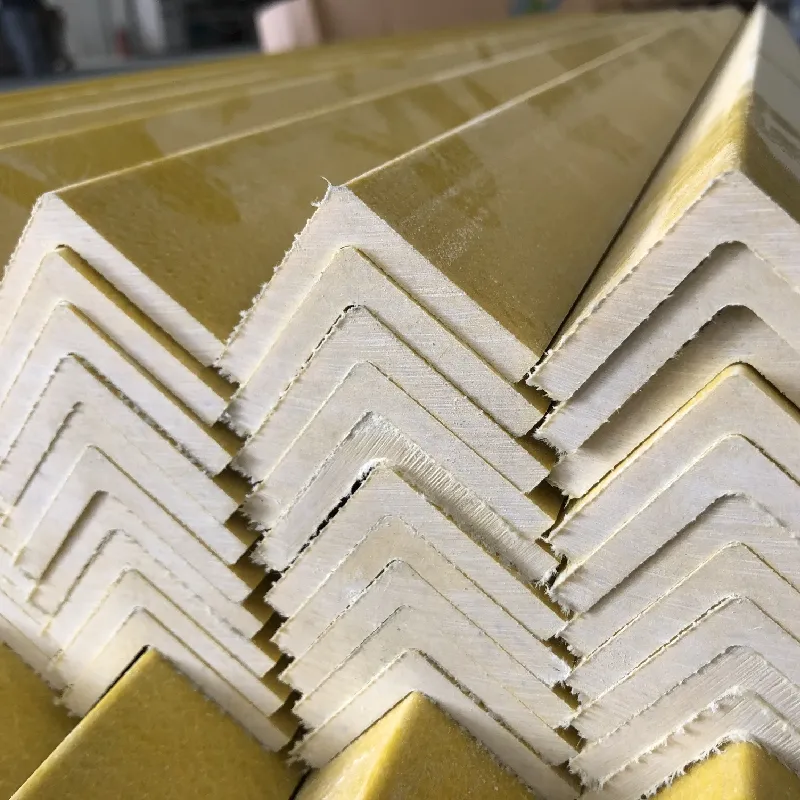

frp grating

Fiberglass Reinforced Plastic (FRP) molded grating represents a revolution in industrial flooring and related applications, combining durability, versatility, and cost-effectiveness in ways that traditional materials struggle to match. Based on real-world experience and industry expertise, FRP molded grating continues to establish itself as a superior option across various sectors.

Trustworthiness is fundamental when considering the lifecycle and maintenance of FRP molded grating. Unlike metal grating, which may require regular painting, galvanizing, or other protective measures, FRP needs minimal upkeep. This reliability makes it a cost-effective long-term investment, reducing repair and replacement expenses. The versatility of FRP molded grating also plays a crucial role in its increasing adoption. Available in various colors, sizes, and panel configurations, it meets specific design and aesthetic needs while providing functionality. Customizable grating solutions mean tailored applications in wastewater treatment facilities, food and beverage processing plants, oil and gas industries, and more. Furthermore, FRP molded grating is environmentally friendly. The production process requires less energy compared to metallic alternatives, and the lifespan of FRP can contribute to sustainability goals by reducing the need for frequent replacements and minimizing resource wastage. In summary, the advantages of FRP molded grating are multifaceted. Its durability, chemical resistance, compliance with safety standards, low maintenance demands, and environmental benefits make it a logical choice for a wide array of applications. Supported by extensive industry experience and rigorous testing, FRP continues to innovate and push boundaries. As organizations prioritize safety, efficiency, and sustainability, FRP molded grating is set to remain an authoritative and trustworthy choice for industrial grating solutions.

Trustworthiness is fundamental when considering the lifecycle and maintenance of FRP molded grating. Unlike metal grating, which may require regular painting, galvanizing, or other protective measures, FRP needs minimal upkeep. This reliability makes it a cost-effective long-term investment, reducing repair and replacement expenses. The versatility of FRP molded grating also plays a crucial role in its increasing adoption. Available in various colors, sizes, and panel configurations, it meets specific design and aesthetic needs while providing functionality. Customizable grating solutions mean tailored applications in wastewater treatment facilities, food and beverage processing plants, oil and gas industries, and more. Furthermore, FRP molded grating is environmentally friendly. The production process requires less energy compared to metallic alternatives, and the lifespan of FRP can contribute to sustainability goals by reducing the need for frequent replacements and minimizing resource wastage. In summary, the advantages of FRP molded grating are multifaceted. Its durability, chemical resistance, compliance with safety standards, low maintenance demands, and environmental benefits make it a logical choice for a wide array of applications. Supported by extensive industry experience and rigorous testing, FRP continues to innovate and push boundaries. As organizations prioritize safety, efficiency, and sustainability, FRP molded grating is set to remain an authoritative and trustworthy choice for industrial grating solutions.

Share

Next:

Latest news

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025