loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor grating clamps

The Significance of Floor Grating Clamps in Industrial Applications

In various industrial sectors, safety and efficiency are paramount. One of the often-overlooked components that play a critical role in ensuring these aspects is the floor grating clamp. These clamps are essential in securing floor grating systems, which are widely used for flooring in industrial plants, warehouses, pedestrian walkways, and other facilities. This article explores the significance of floor grating clamps, their types, installation methods, and their benefits in maintaining safe working environments.

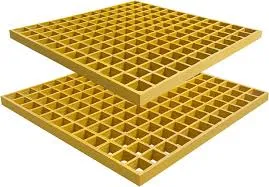

Understanding Floor Grating

Floor grating refers to a type of flooring made from a series of metal bars or sheets arranged in a grid pattern, leaving spaces that allow for light, air, drainage, and visibility while providing a sturdy surface for heavy loads. Common materials used for floor grating include steel, aluminum, and fiberglass. These materials ensure durability and resistance to corrosive substances, making them suitable for various industrial applications.

The Role of Floor Grating Clamps

Floor grating clamps are designed to secure grating panels to supporting structures, maintaining stability and safety. Without proper clamping, floor grating can shift or become dislodged, posing serious hazards to workers and equipment. The clamps help prevent accidents caused by slipping or tripping, which can lead to injuries.

There are various types of floor grating clamps, each serving specific needs and applications

1. Standard Grating Clamps These are the most common type and are typically galvanized to prevent rust. They provide a solid grip on the grating and are easy to install.

2. Heavy-Duty Clamps Designed for environments with heavy traffic or loads, these clamps can hold larger panels and withstand greater stresses.

3. Quick-Release Clamps Ideal for applications requiring frequent access to the understructure for maintenance, quick-release clamps allow users to remove and replace grating panels quickly without tools.

Installation Process

floor grating clamps

Installing floor grating clamps involves several steps to ensure they are correctly placed and secure. First, the grating panels are laid in their designated positions. Next, the clamps are attached to the supporting beams or frame, aligning them with the edges of the grating. After that, the clamps are tightened, ensuring a secure fit. It is crucial to follow manufacturer specifications regarding torque settings and spacing to guarantee the integrity of the installation.

Before finalizing the installation, a thorough inspection should be carried out to identify any loose clamps or misaligned panels. This step is essential for ensuring a safe and stable flooring system.

Benefits of Using Floor Grating Clamps

The use of floor grating clamps brings several benefits to industries that employ grating systems

1. Enhanced Safety By securing grating panels effectively, clamps reduce the risk of slips and falls, contributing to a safer work environment.

2. Increased Durability Properly installed clamps prolong the lifespan of the floor grating by preventing damage from shifting, thus reducing maintenance costs.

3. Easy Access With quick-release clamps, maintenance work can be performed efficiently, allowing for regular inspections of the underlying structures without significant downtime.

4. Versatility The availability of different types of clamps allows industries to choose solutions tailored to their specific needs, providing flexibility in design and implementation.

5. Cost-Effectiveness Investing in high-quality clamps can minimize potential accidents and injuries, ultimately saving companies money on insurance claims and worker compensation.

Conclusion

In conclusion, floor grating clamps, while often taken for granted, are vital components in industrial flooring systems. They ensure the stability and safety of grating installations, which are crucial for maintaining a secure working environment. With various types available, industries can find suitable solutions tailored to their specific needs. Recognizing the importance of these clamps is essential for any organization committed to enhancing workplace safety and operational efficiency. By prioritizing proper installation and maintenance of floor grating clamps, companies can foster safer and more productive environments for their employees.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025