loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

जनवरी . 14, 2025 12:16

Back to list

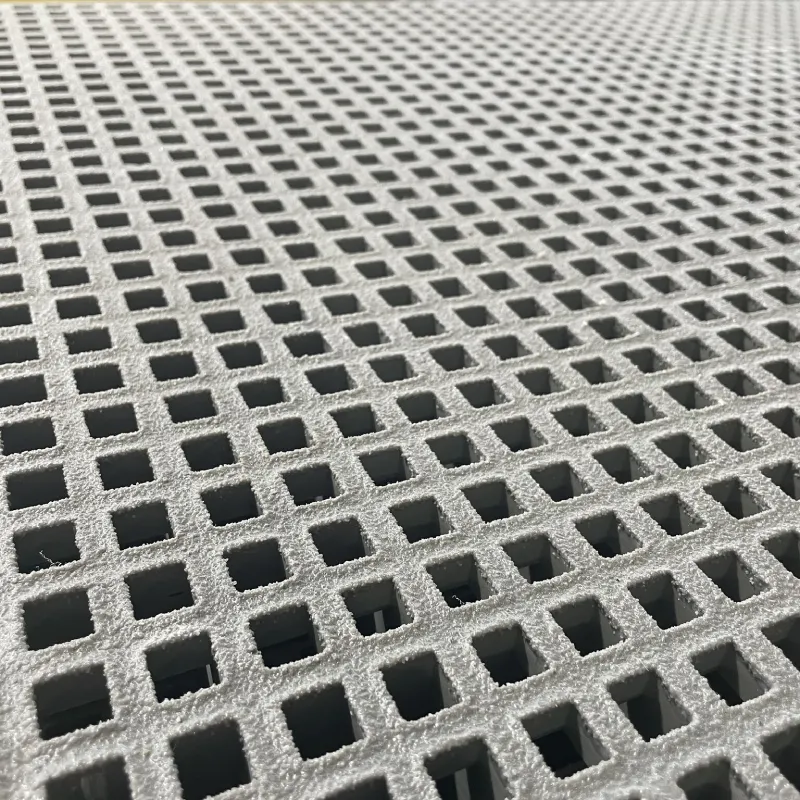

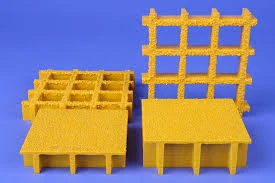

frp micro mesh grating

Moulded fibreglass grating has emerged as a revolutionary product in numerous industries, offering a blend of durability, safety, and functionality. Its unique composition, predominantly created from interwoven glass fibers and a choice of resins, provides a versatile solution that caters to various operational requirements. This comprehensive amalgamation results in a grating that is both lightweight and immensely robust, appealing to sectors such as marine, chemical processing, oil and gas, and food and beverage industries.

Moreover, environmental considerations are increasingly becoming a critical aspect of product selection. Moulded fibreglass grating is recognized for its sustainable attributes. During its production, less energy is consumed compared to metal alternatives, and its longevity reduces the frequency of replacement, promoting a more sustainable lifecycle. Additionally, manufacturers are continually innovating to enhance the recyclability of fibreglass, aligning with global sustainability goals and reducing environmental footprint. The expertise behind producing high-quality moulded fibreglass grating involves precision engineering and a deep understanding of material science. Trusted manufacturers employ rigorous quality control processes, often adhering to strict domestic and international standards to ensure that the grating performs excellently even in the most demanding situations. This commitment to excellence reassures clients that they are investing in a product that has been crafted with care and expertise, fulfilling both their immediate and long-term needs. In conclusion, choosing moulded fibreglass grating is a decision that resonates with prudence. It embodies a product that not only meets but often exceeds the expectations of durability, safety, and adaptability. Industries that value efficiency and reliability find it a partner in enhancing operational capabilities while ensuring economic and environmental considerations are thoroughly addressed. With a product backed by years of proven experience, expertise, and a reputation of trust, moulded fibreglass grating stands as an authoritative choice in an ever-evolving industrial landscape.

Moreover, environmental considerations are increasingly becoming a critical aspect of product selection. Moulded fibreglass grating is recognized for its sustainable attributes. During its production, less energy is consumed compared to metal alternatives, and its longevity reduces the frequency of replacement, promoting a more sustainable lifecycle. Additionally, manufacturers are continually innovating to enhance the recyclability of fibreglass, aligning with global sustainability goals and reducing environmental footprint. The expertise behind producing high-quality moulded fibreglass grating involves precision engineering and a deep understanding of material science. Trusted manufacturers employ rigorous quality control processes, often adhering to strict domestic and international standards to ensure that the grating performs excellently even in the most demanding situations. This commitment to excellence reassures clients that they are investing in a product that has been crafted with care and expertise, fulfilling both their immediate and long-term needs. In conclusion, choosing moulded fibreglass grating is a decision that resonates with prudence. It embodies a product that not only meets but often exceeds the expectations of durability, safety, and adaptability. Industries that value efficiency and reliability find it a partner in enhancing operational capabilities while ensuring economic and environmental considerations are thoroughly addressed. With a product backed by years of proven experience, expertise, and a reputation of trust, moulded fibreglass grating stands as an authoritative choice in an ever-evolving industrial landscape.

Share

Next:

Latest news

-

Why FRP Grating Panels are the Best Choice for Your Industrial NeedsNewsMay.09,2025

-

He Versatility and Strength of Mini Mesh Grating for Your ProjectsNewsMay.09,2025

-

The Durability and Versatility of FRP Profiles and Pultruded SectionsNewsMay.09,2025

-

The Advantages of Sectional Tanks for Efficient Water StorageNewsMay.09,2025

-

he Advantage of FRP Pressure Tanks and Pressure VesselsNewsMay.09,2025

-

Maximize Safety and Durability with Covered Grating SolutionsNewsMay.09,2025

-

Understanding SMC Panel TanksNewsApr.21,2025