loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Micro Mesh Grating: Safe, Strong, Anti-Slip Solutions

The Unseen Foundation: Decoding the Critical Role of FRP Micro Mesh Grating in Industrial Excellence

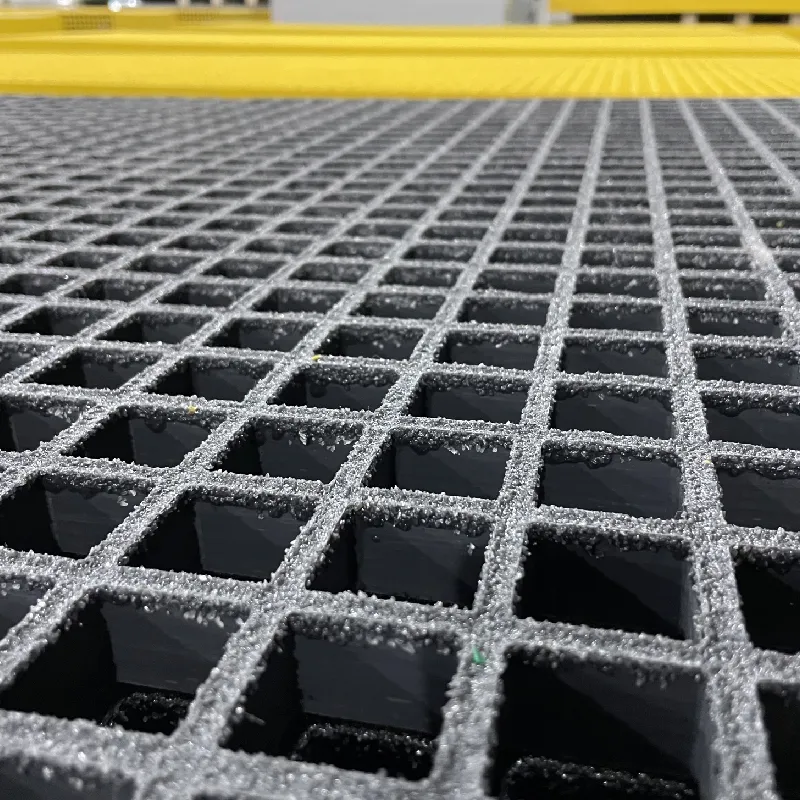

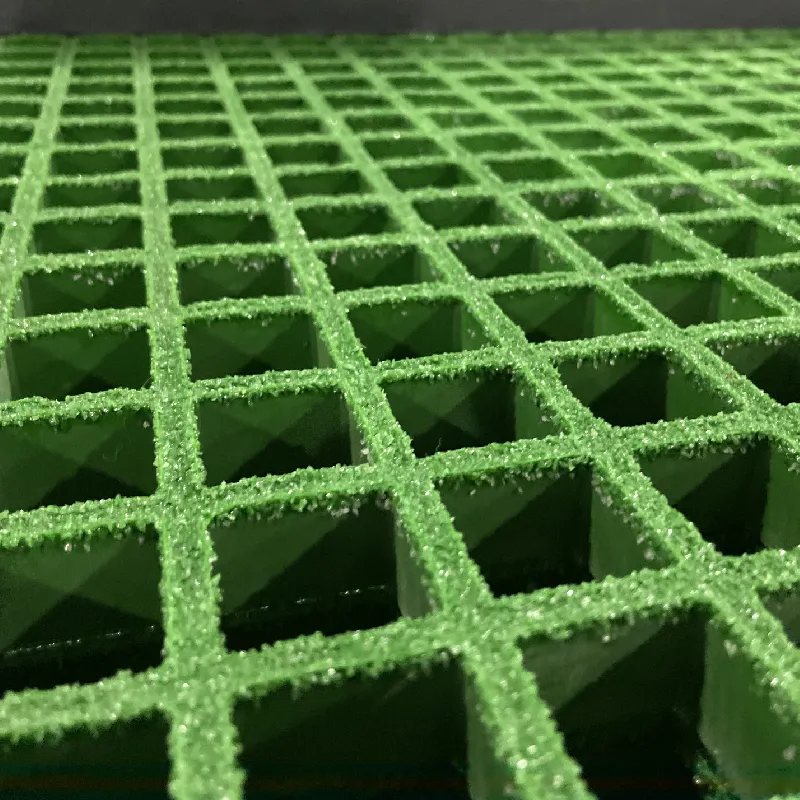

In the relentless pursuit of operational efficiency, safety, and structural longevity across demanding industrial landscapes, the strategic selection of materials stands as a paramount decision. Among the innovative solutions revolutionizing infrastructure and safety, frp micro mesh grating emerges as an indispensable cornerstone, particularly in environments where traditional metallic materials falter due to corrosion, conductivity, or weight limitations. This specialized form of fiberglass reinforced plastic (FRP) grating is meticulously engineered with a significantly finer mesh opening compared to standard gratings, typically featuring clear openings as small as 12x12mm or 19x19mm. This design attribute offers unparalleled advantages, including enhanced safety against the inadvertent dropping of small tools, bolts, or critical debris into sensitive machinery or hazardous areas, improved underfoot comfort for personnel, and superior load distribution for areas with concentrated foot traffic or small wheeled equipment. Its application is becoming increasingly widespread and vital for walkways, trench covers, elevated platforms, and accessways within sensitive industrial zones. The global demand for advanced composite materials, encompassing a broad spectrum of fiberglass gratings including frp platform grating and frp protruded grating, is propelled by an escalating awareness of the total cost of ownership (TCO), which extends far beyond the initial purchase price to encompass long-term maintenance, replacement cycles, safety compliance, and energy efficiency. Industries such as petrochemicals, water and wastewater treatment, power generation, marine, food and beverage, and pharmaceutical manufacturing are strategically transitioning from conventional metallic gratings to advanced FRP solutions. This shift is driven by FRP's unparalleled resistance to corrosive chemicals, saline environments, and UV radiation, coupled with significantly reduced maintenance requirements and inherently non-conductive properties, making it intrinsically safer in electrically charged areas. This strategic industrial pivot underscores a broader, imperative trend towards sustainable, durable, and intrinsically safer operational infrastructures where materials must robustly withstand aggressive chemical exposures, extreme temperature fluctuations, and heavy operational loads without compromising structural integrity or worker safety. The distinct advantages of frp micro mesh grating, when compared to its counterparts like standard frp platform grating, which offers larger mesh sizes, or frp protruded grating, known for its superior unidirectional strength, lie in its unique combination of enhanced load-bearing capacity for smaller, concentrated loads, exceptional anti-slip characteristics due to increased surface contact, and improved aesthetic appeal, making it a preferred choice for public access areas, facilities requiring stringent safety protocols against dropped items, or specific cleanroom environments. Understanding the nuanced engineering, versatile application spectrum, and profound economic benefits of these specialized gratings is paramount for B2B decision-makers seeking to optimize their capital investments and operational expenditures, thereby ensuring long-term performance, regulatory compliance, and an elevated standard of workplace safety. This comprehensive technical guide will delve into the intricate details of its advanced manufacturing processes, critical technical specifications, diverse application scenarios, and the pivotal factors that establish a manufacturer's authority, expertise, experience, and trustworthiness in this highly specialized field, ultimately highlighting why solutions like the Holiday Special Offers GRP FRP Gratings Fiberglass Grates represent a valuable and strategic investment for modern industrial enterprises.

Precision Engineering: Demystifying the Advanced Manufacturing Process of FRP Micro Mesh Grating

The production of high-performance frp micro mesh grating is a sophisticated and meticulously controlled process, primarily relying on advanced composite manufacturing techniques, predominantly molded grating or, less commonly for micro mesh, assembled pultruded components. Each method offers distinct advantages in terms of structural integrity, consistency, and specific application suitability. The fundamental raw materials consist of high-quality thermosetting resins, typically unsaturated polyester, vinyl ester, or phenolic, which are chosen based on the precise chemical resistance, fire retardancy, and mechanical property requirements of the end application. These polymer matrix systems are robustly reinforced with continuous fiberglass rovings and mats, providing the exceptional strength-to-weight ratio, dimensional stability, and impact resistance that defines FRP products. In the prevalent molded grating process, a carefully formulated liquid resin mixture, combined with fiberglass rovings and a precise ratio of catalyst, pigment, and other additives, is strategically poured into a pre-designed, heated mold that dictates the intricate grid pattern and specific fine mesh size of the grating. This mold is engineered to create a uniform, monolithic panel where resin encapsulates every fiberglass strand, ensuring bi-directional strength, uniform load distribution, and a high percentage of open area, which is vital for efficient drainage and airflow. The mold is then heated to initiate a precise polymerization reaction (curing) that solidifies the resin into a strong, rigid, and intrinsically corrosion-resistant panel. This manufacturing method results in an isotropic product, highly resistant to fatigue, impact, and delamination, making it particularly suitable for environments with dynamic loads or requiring multi-directional support.

Crucial to the long-term reliability and exceptional performance of frp micro mesh grating are the stringent and multi-layered quality control measures meticulously implemented at every stage of the manufacturing process. This begins with the rigorous incoming inspection of all raw materials, ensuring that resins meet precise viscosity, gel time, cure time, and chemical resistance profiles, and that fiberglass rovings adhere to strict tensile strength, modulus, and uniformity standards (e.g., as per ASTM D578). During the molding phase, continuous monitoring of critical parameters such as temperature gradients, pressure, resin-to-glass ratios, and catalyst levels is absolutely essential to guarantee consistent mechanical properties, minimize voids, and prevent imperfections. Post-cure, each panel of frp micro mesh grating undergoes a battery of rigorous physical and mechanical tests. These typically include flexural strength and modulus tests (ASTM D790), compressive strength (ASTM D695), tensile strength (ASTM D638), and impact resistance (ASTM D256). Fire retardancy is meticulously verified through internationally recognized tests like ASTM E84 for flame spread and smoke development, ensuring compliance with critical safety standards, especially for applications in enclosed spaces or areas with high fire risks. Adherence to international quality management systems such as ISO 9001:2015 is paramount, demonstrating that the entire manufacturing process is not only highly efficient but also consistently produces high-quality, reliable, and compliant products. The expected service life of properly specified, expertly manufactured, and correctly installed frp micro mesh grating can reliably exceed 20-25 years, even in the most highly corrosive or aggressive industrial environments. This extended lifespan significantly outperforms traditional steel or aluminum alternatives, which frequently demand costly and disruptive maintenance, painting, or premature replacement. This impressive longevity directly translates into substantially reduced lifecycle costs and minimizes operational disruptions, making it an economically prudent and strategically advantageous choice for industries such as petrochemical plants, where constant exposure to aggressive chemicals necessitates robust, corrosion-proof materials; in metallurgical facilities, where non-conductivity is crucial around high-voltage electrical equipment and molten metals; and in water treatment plants, where exceptional resistance to chlorine, ozone, and other purifying agents is paramount. The meticulous attention to detail in material selection, precise process control, and rigorous quality assurance throughout manufacturing directly culminates in the superior performance, enhanced safety, and tangible economic advantages that define high-quality frp micro mesh grating in diverse, challenging industrial applications. This also intrinsically promotes energy efficiency by reducing the need for material replacement and offering improved light transmission in certain designs, which can reduce reliance on artificial lighting beneath structures.

Unpacking the Specs: Critical Technical Parameters and Performance Metrics of FRP Micro Mesh Grating

Selecting the optimal frp micro mesh grating for highly specific industrial applications necessitates an exhaustive and precise understanding of its intricate technical parameters and performance specifications. These critical metrics directly dictate the grating's absolute suitability for particular operational environments, its maximum safe load-bearing capabilities, its integrated safety features, and its projected long-term durability under strenuous conditions. Key parameters include the precise mesh size, the overall panel dimensions, the structural thickness (or height) of the grating, and crucially, the specific type of resin system utilized in its composite matrix. For frp micro mesh grating, the distinguishing feature is its significantly finer clear opening compared to conventional gratings, typically ranging as small as 12x12mm (approximately 0.5" x 0.5") or 19x19mm (approximately 0.75" x 0.75"), which is a paramount safety feature designed to prevent small tools, nuts, bolts, or other critical debris from falling through into sensitive machinery, hazardous chemical baths, or below-grade systems. This aspect makes it invaluable in precision manufacturing areas, offshore platforms, and public access walkways. Standard panel dimensions often include common industrial sizes such as 3'x10', 4'x8', 4'x12', 5'x10', and 5'x12', though leading manufacturers provide extensive custom sizing capabilities to minimize on-site cutting, reduce material waste, and optimize installation time for complex projects. Thicknesses commonly range from 1" (25mm) to 2.5" (63mm), with incrementally thicker panels inherently offering proportionally higher load capacities and greater span capabilities, allowing for optimized structural design and reduced support requirements.

The selection of the appropriate resin system is arguably the most critical determinant of the frp micro mesh grating's long-term performance and chemical compatibility in aggressive environments. Isophthalic polyester resin serves as a versatile, general-purpose, and cost-effective option, offering robust corrosion resistance against a broad spectrum of chemicals, making it highly suitable for numerous general industrial and wastewater treatment applications. For environments encountering highly corrosive chemicals, including strong acids, concentrated alkalis, and various organic solvents, vinyl ester resin provides unparalleled chemical resistance, establishing it as the ideal choice for demanding chemical processing plants, pulp and paper mills, and electroplating facilities. Phenolic resin, on the other hand, distinguishes itself by offering exceptional fire resistance, extremely low smoke generation, and high temperature stability, making it critically important for applications in the oil and gas industry, power generation, and mass transit where stringent fire safety regulations and thermal performance are paramount. Beyond the fundamental material composition, crucial performance metrics such as ultimate load capacity are of utmost importance, which are meticulously determined by the grating's span, thickness, and the specific load requirements (whether concentrated point loads or uniformly distributed loads), typically measured in pounds per square foot (PSF) or kilograms per square meter (Kg/m²). For instance, a 1.5" thick frp micro mesh grating with a 1" clear span could safely support substantial point loads, while distributed loads can be significantly higher, often in the range of hundreds of pounds per square foot. Fire retardancy is a non-negotiable safety feature, often certified by standards such as ASTM E84 (Class 1 flame spread rating), ensuring the grating will not propagate flame and generates minimal smoke, a vital safety characteristic for personnel evacuation and property protection. Slip resistance is profoundly enhanced through various expertly engineered surface finishes, including integral grit surfaces (comprising durable quartz, silica, or aluminum oxide particles permanently embedded in the top layer), concave surfaces for natural drainage and grip, or specialized smooth finishes where required for hygiene in cleanroom environments. Other pivotal properties include very low thermal conductivity (FRP acts as an effective insulator, minimizing heat transfer), superior UV stability (achieved through advanced UV inhibitors integrated into the resin formulation to prevent degradation from prolonged sunlight exposure), and absolute electrical non-conductivity, which eliminates the critical need for complex grounding systems and inherently prevents accidental electrocution, representing a significant safety advantage over metallic gratings in electrical substations or near energized equipment. The meticulously compiled data presented in the following table outlines typical parameters for high-quality frp micro mesh grating, providing a clear, empirical reference for informed engineering and procurement decisions.

| Parameter | Common Specifications / Range | Applicable Standard / Test Method |

|---|---|---|

| Mesh Size (Clear Opening) | Typically 12x12mm (0.5"x0.5") to 19x19mm (0.75"x0.75"); smaller custom options available. | Internal Manufacturing Tolerance, Client Specific |

| Panel Thickness (Height) | 25mm (1"), 30mm (1.2"), 38mm (1.5"), 50mm (2"), 63mm (2.5") | ISO 4478, ASTM E29 |

| Standard Panel Sizes | 3'x10', 4'x8', 4'x12', 5'x10', 5'x12' (Custom sizes and cuts available) | Manufacturer Specific, Project Dependent |

| Resin Type Options | Orthophthalic, Isophthalic, Vinyl Ester (Superior Chemical), Phenolic (Superior Fire) | ASTM D4067, Client Specified |

| Fire Retardancy | ASTM E84 Class 1 (Flame Spread Index < 25), UL Listed where applicable | ASTM E84, NFPA 130 (for Phenolic) |

| Ultimate Flexural Strength | 30,000 – 45,000 psi (200-310 MPa) for standard thickness (typical ranges) | ASTM D790 |

| Ultimate Compressive Strength | 20,000 – 35,000 psi (140-240 MPa) (typical ranges) | ASTM D695 |

| Coefficient of Thermal Expansion | 10-20 x 10^-6 in/in/°F (Comparable to aluminum, low) | ASTM D696 |

| UV Resistance | Excellent (with integrated UV inhibitors for outdoor stability) | ASTM G154 / G155 |

| Operating Temperature Range | -60°F to 200°F (-50°C to 95°C) for Isophthalic; up to 300°F (150°C) for Phenolic/Vinyl Ester | Manufacturer Specific, Resin Dependent |

| Weight (e.g., 1.5" thickness) | Approx. 2.0-3.5 lbs/sq ft (9.8-17.1 kg/m²), significantly lighter than steel | Calculated based on density & composition |

| Corrosion Resistance | Excellent against acids, alkalis, salts, and various solvents (resin dependent) | ASTM C581 (Chemical Resistance) |

Versatility in Action: Diverse Application Scenarios and Sector-Specific Advantages of FRP Micro Mesh Grating

The distinctive blend of characteristics inherent to frp micro mesh grating renders it an exceptionally versatile and critically important material, finding indispensable applications across an expansive range of industries where traditional materials are fundamentally prone to premature failure, pose significant safety hazards, or demand excessive maintenance. Its foremost advantage stems from its superlative corrosion resistance, which positions it as an indispensable choice in highly aggressive and chemically charged environments such as petrochemical plants and refineries. Here, frp micro mesh grating robustly withstands relentless exposure to strong acids, concentrated alkalis, corrosive gases, and a vast array of solvents, thereby drastically reducing maintenance downtime, eliminating the need for costly protective coatings, and significantly lowering replacement costs compared to conventional steel gratings that rapidly succumb to rust and chemical attack. In municipal water and wastewater treatment facilities, where constant contact with harsh chemicals like chlorine, ozone, hydrogen sulfide, and various biological agents is unavoidable, frp micro mesh grating excels as durable walkways, reliable trench covers, and resilient tank covers, providing a robust, non-degrading solution that remains structurally sound and safe over decades. The fine mesh size characteristic of frp micro mesh grating is particularly beneficial in these sensitive applications, effectively preventing small tools, bolts, or other critical components from accidentally falling into tanks, basins, or intricate machinery, thereby enhancing operational safety, preventing equipment damage, and improving overall process efficiency. Similarly, in demanding marine and offshore environments, ranging from oil and gas rigs to coastal processing facilities and ship decks, its inherently non-corrosive nature and remarkably lightweight properties dramatically reduce structural load on platforms and vessels, while virtually eliminating maintenance associated with saltwater exposure, offering a far more durable and cost-effective alternative to steel in corrosive, saline-laden atmospheres.

Beyond its unparalleled chemical resistance, the intrinsically non-conductive nature of frp micro mesh grating constitutes a paramount safety feature in all industries involving electricity or sensitive electronic equipment. In power generation plants, electrical substations, utility corridors, and telecommunication facilities, its insulating properties eliminate the critical risk of accidental electrical shock, making it an ideal choice for safe work platforms, transformer pads, switchgear enclosures, and battery rooms. This inherent electrical safety property stands in sharp contrast to metallic gratings, which are highly conductive and necessitate extensive, costly, and complex grounding systems to mitigate electrocution risks. The lightweight nature of frp micro mesh grating also profoundly simplifies installation logistics, significantly reducing labor costs, eliminating the need for heavy lifting machinery, and accelerating project timelines, which is particularly advantageous in remote, high-altitude, or confined spaces where equipment access is challenging. Its superior strength-to-weight ratio ensures it can safely support substantial loads while maintaining absolute structural integrity, often outperforming steel on a pound-for-pound basis in specific load-bearing applications. In the stringent food and beverage industry, its hygienic properties – being effortlessly easy to clean, inherently resistant to bacterial growth, and non-porous – make it an optimal choice for drainage systems, processing areas, and wash-down zones, strictly complying with the most stringent sanitation and hygiene regulations. For pharmaceutical manufacturing and cleanroom environments, the inert nature of FRP prevents contamination, shedding, and ensures a sterile, particulate-free environment crucial for product integrity. Even in modern architectural applications, the aesthetic versatility (available in a broad spectrum of integrated colors) and exceptional durability of frp micro mesh grating allow for innovative and functional design elements in public spaces, parks, building facades, and urban infrastructure, seamlessly combining enhanced safety and long-term performance with contemporary design aesthetics. When meticulously comparing types, while standard frp platform grating offers excellent general-purpose support with larger openings, and frp protruded grating provides superior unidirectional strength and stiffness ideal for longer spans and heavy linear loads, frp micro mesh grating distinctly stands out for its unique combination of enhanced safety against falling objects, superior underfoot comfort, and a higher open area percentage coupled with smaller openings, making it the superior choice for high-traffic pedestrian walkways, areas accommodating small-wheeled carts or trollies, or where prevention of fine debris ingress is a critical operational requirement. These distinct and compelling advantages profoundly underscore why frp micro mesh grating is a highly preferred, strategic solution for forward-thinking B2B entities making long-term investments in durable, safe, and highly efficient industrial infrastructure.

Beyond Durability: Unrivaled Technical Advantages and Performance Benefits of FRP Micro Mesh Grating

The compelling and escalating adoption of frp micro mesh grating across a multitude of critical industrial sectors is not merely a transient trend, but a profound and strategic pivot driven by a comprehensive suite of technical advantages that collectively and demonstrably surpass the inherent capabilities and limitations of traditional construction materials like steel, aluminum, or concrete. At the absolute forefront of these transformative benefits is its extraordinary and unparalleled corrosion resistance. Unlike metallic gratings that are highly susceptible to rust, galvanic corrosion, and rapid degradation when exposed to aggressive chemical environments, FRP gratings, particularly those meticulously manufactured utilizing high-performance vinyl ester or phenolic resins, can robustly withstand prolonged and intense exposure to strong acids, concentrated alkalis, various salts, and a vast array of organic solvents without any compromise to their structural integrity or aesthetic appearance. This intrinsic chemical inertness directly translates into a dramatically extended service life, drastically reducing the frequency and exorbitant cost of material replacement and time-consuming maintenance interventions, thereby contributing profoundly to a significantly lower total cost of ownership over the entire operational lifecycle of an industrial asset. This characteristic is exceptionally vital in highly demanding environments such as chemical processing plants, pulp and paper mills, electroplating facilities, and metallurgical operations, where chemical spills or constant exposure to corrosive fumes would rapidly and catastrophically destroy conventional metallic materials, leading to costly failures and safety hazards. The material's inherently low thermal conductivity also plays a crucial, often overlooked, role; FRP functions as an extremely effective insulator, minimizing heat transfer across platforms and walkways. This property can lead to substantial energy savings by reducing heat loss in certain applications or, critically, by preventing hazardous heat transfer to sensitive equipment or personnel in high-temperature operating environments. Furthermore, its remarkably lightweight nature, typically one-third to one-half the weight of equivalent steel grating, fundamentally revolutionizes installation logistics. The reduced mass simplifies material handling, substantially lowers transportation costs, and frequently eliminates the absolute necessity for heavy lifting machinery or specialized equipment, thereby accelerating project timelines and profoundly improving site safety for installation crews. This characteristic is especially beneficial for expansive, large-scale retrofit projects or for installations situated in remote, difficult-to-access, or structurally limited locations.

Another profound and distinguishing advantage of frp micro mesh grating is its absolute electrical non-conductivity. This property inherently and effectively protects personnel from accidental electrical shocks in areas where energized equipment, high voltage lines, or potential stray currents are present, making it the material of unambiguous choice for crucial applications in power plants, electrical substations, electrical control rooms, and any facility where electrical safety is an uncompromisable paramount concern. Unlike highly conductive metallic materials, FRP intrinsically does not require costly, complex, or time-consuming grounding and bonding procedures, thereby significantly simplifying both the design and installation phases of a project. Its non-magnetic properties are also remarkably advantageous in highly sensitive environments such as MRI rooms in medical facilities, scientific research laboratories, or specific manufacturing areas where magnetic interference must be rigorously avoided to ensure precision and accuracy. Impact resistance and remarkable energy absorption capabilities are also significant performance differentiators. While traditional steel gratings can permanently deform, dent, or buckle under impact, frp micro mesh grating possesses a unique degree of elastic memory and resilience, allowing it to absorb significant impact energy and often return to its original shape without permanent damage, thereby offering superior resistance to repeated impacts, dynamic loads, and operational vibrations. This inherent resilience significantly enhances safety and longevity in dynamic industrial settings. The expertly engineered surface finishes, such such as integral grit (a composite of quartz or aluminum oxide particles permanently embedded in the top resin layer), provide exceptional and bi-directional slip resistance, even in the most challenging wet, oily, greasy, or icy conditions, thereby dramatically reducing the critical risk of slips, trips, and falls – which remain a leading cause of industrial accidents and worker injuries. This vital ergonomic safety benefit is further amplified by the finer mesh pattern of frp micro mesh grating, which inherently provides a far more comfortable, stable, and secure walking surface, especially for individuals wearing shoes with smaller heels, or for areas requiring the prevention of small object ingress. This improved underfoot comfort and stability can directly contribute to reduced worker fatigue over extended shifts. Beyond these compelling technical merits, FRP is remarkably maintenance-free, requiring no cyclical painting, corrosive welding repairs, or elaborate cleaning regimens, unlike metallic gratings which necessitate regular, costly inspection and continuous corrosion mitigation strategies. This extremely low maintenance requirement, coupled with a projected service life that frequently exceeds 25 years, firmly positions frp micro mesh grating as a superior, highly strategic, and exceptionally long-term investment, consistently delivering sustained peak performance, unparalleled safety, and robust operational reliability throughout its entire operational lifespan, translating directly into profound tangible economic benefits and significantly improved operational efficiency for discerning B2B enterprises.

Choosing Wisely: Manufacturer Comparison and Strategic Partner Selection for FRP Grating Solutions

For discerning B2B entities, the meticulous selection of a manufacturing partner for critical composite solutions like frp micro mesh grating, alongside complementary products such as frp platform grating or frp protruded grating, is an endeavor that is as critically important as the product itself. A truly reliable and reputable manufacturer embodies the highest standards of expertise, extensive experience, undisputed authoritativeness, and unwavering trustworthiness, thereby providing absolute assurance that the procured materials will consistently meet, and often exceed, stringent international industry standards and precise project-specific demands. Key criteria for the comprehensive evaluation of potential partners include their portfolio of comprehensive certifications, a demonstrably proven track record of successful project executions, expansive customization capabilities, a robust commitment to research and development (R&D), substantial production capacity, and unequivocally excellent post-sales technical support. Reputable manufacturers will hold fundamental international certifications such as ISO 9001:2015 for quality management systems, which serves as a foundational testament to their unwavering commitment to consistent product quality and optimized process efficiency. Furthermore, strict adherence to a broad spectrum of industry-specific standards, including ASTM (American Society for Testing and Materials) for critical material properties (e.g., ASTM D790 for flexural strength, ASTM D638 for tensile strength, ASTM E84 for flame spread and smoke development), and ANSI (American National Standards Institute) for general safety and performance standards, is absolutely non-negotiable for high-performance applications. An extensively experienced manufacturer will possess a long and distinguished history of successful project executions, which is transparently reflected in their many years of dedicated service in the composites industry and a diverse, high-profile client portfolio, providing undeniable confidence in their inherent ability to consistently deliver complex, large-scale, and mission-critical orders on time and within budget. For instance, a company with over 15-20 years of specialized experience in the advanced composites industry has inevitably amassed invaluable and practical knowledge in cutting-edge material science, intricate engineering design principles, and overcoming complex real-world application challenges.

Beyond offering standard product lines, a premier manufacturer of high-quality frp micro mesh grating should unequivocally demonstrate advanced and highly flexible customization capabilities. This critical aptitude includes the inherent ability to precisely fabricate panels to highly specific dimensions, incorporate intricate specialized cut-outs for pipes, columns, or machinery foundations, and implement precise panel allocations to minimize material waste and optimize utilization across expansive or geometrically complex areas. For instance, a particular industrial facility may require a very specific load-bearing capacity over an unusually long span, or a uniquely aggressive corrosive environment may necessitate a non-standard resin blend with enhanced chemical resistance properties that extend far beyond typical standard offerings. A leading and authoritative manufacturer will possess state-of-the-art CNC cutting capabilities, advanced robotic fabrication lines, and highly experienced, expertly trained fabrication teams, enabling them to consistently meet exact specifications with unparalleled precision and efficiency. Furthermore, customization extends to a diverse range of aesthetic and functional attributes. Clients often have the flexibility to specify precise color matching to align with facility safety codes (e.g., vibrant yellow for designated caution areas, safety green for emergency zones, or highly visible red for fire safety areas) or to integrate seamlessly with corporate branding guidelines, utilizing durable pigments embedded directly and permanently into the resin matrix for long-lasting vibrancy that will not chip, peel, or fade like conventionally painted surfaces. Surface finishes can also be meticulously tailored; while integral grit top surfaces are standard for superior slip resistance in industrial settings, smooth, non-porous surfaces might be rigorously preferred in pharmaceutical cleanrooms for ease of frequent sterilization and to prevent particulate accumulation, or specialized concave surfaces for general industrial use where drainage and moderate grip are required. Beyond the grating panels themselves, a truly comprehensive customization service might include the seamless integration of ancillary components such as custom-designed handrail systems, robust ladder cages, non-slip stair treads, or even complete modular platform assemblies, all fabricated from matching FRP materials. This holistic and integrated approach ensures absolute system compatibility, simplifies the procurement process for the client, and guarantees optimal performance across the entire structure. The expert design and engineering consultation services provided by top-tier manufacturers are exceptionally invaluable throughout this entire process. They collaborate intimately with clients, conducting thorough site assessments, performing precise load calculations, developing detailed CAD drawings, and recommending optimal resin systems and panel configurations to ensure the ultimate composite solution is not only structurally sound and maximally efficient but also rigorously compliant with all relevant local, national, and international safety and environmental standards. This deep, consultative partnership profoundly mitigates potential risks, significantly optimizes operational performance, and unequivocally guarantees that the investment in high-quality frp micro mesh grating yields the most effective, durable, and intrinsically safe solution meticulously tailored to the project's unique operational demands and long-term safety requirements. Such an unwavering commitment to bespoke engineering and client-centric solutions clearly differentiates top-tier manufacturers, demonstrating their profound understanding of complex client needs and their proven capacity to deliver truly optimized and innovative composite solutions.

Tailored Excellence: Leveraging Customization Solutions for Optimized FRP Micro Mesh Grating Applications

While standard sizes and configurations of frp micro mesh grating effectively serve a broad array of general industrial needs, the intrinsic and profound value proposition of a truly proficient and client-focused manufacturer often lies in their exceptional ability to provide bespoke, tailored customization solutions. Every complex industrial project, large or small, invariably possesses unique spatial constraints, specific structural requirements, and distinct environmental demands, rendering a simplistic "one-size-fits-all" approach not only inefficient but, at times, fundamentally compromising to safety and operational efficacy. Custom fabrication ensures that the FRP grating panels are meticulously engineered and precisely manufactured to integrate seamlessly and flawlessly into even the most intricate and complex infrastructures, significantly minimizing the need for costly and time-consuming on-site cutting, which directly translates into substantial material cost savings, drastically reduced labor expenses, and accelerated overall installation timelines. This advanced customization capability extends far beyond mere dimensional adjustments or standard panel sizes to encompass the production of highly specialized shapes, intricate and precise cut-outs for critical pipes, structural columns, machinery foundations, or access points, and meticulous panel allocations designed to optimize material utilization across expansive or geometrically challenging areas. For example, a specialized chemical processing facility might demand a very specific load-bearing capacity over an unusually long or irregular span, or a uniquely aggressive corrosive environment may critically necessitate a non-standard, custom resin blend with enhanced chemical resistance properties that extend far beyond typical commercially available offerings. A leading manufacturer will possess cutting-edge CNC (Computer Numerical Control) cutting capabilities, advanced robotic fabrication lines, and a team of highly experienced, expertly trained fabrication technicians, enabling them to meet even the most exact and complex specifications with unparalleled precision, consistent accuracy, and superior efficiency.

Furthermore, the scope of customization for frp micro mesh grating extends comprehensively to various crucial aesthetic and functional attributes. Clients frequently have the flexibility to specify precise color matching to strictly align with stringent facility safety codes (e.g., OSHA-compliant yellow for caution areas, safety green for designated safe zones) or to seamlessly integrate with overarching corporate branding guidelines, utilizing durable, UV-stable pigments permanently embedded directly into the resin matrix for long-lasting vibrancy that will not chip, peel, or fade over time like conventional painted surfaces. The surface finishes can also be meticulously tailored to specific operational requirements; while integral grit top is the industry standard for superior slip resistance in industrial environments, perfectly smooth surfaces might be rigorously preferred in pharmaceutical cleanrooms for maximum ease of frequent sterilization and to prevent particulate accumulation, or specialized concave surfaces can be opted for general industrial use where both effective drainage and reliable grip are required. Beyond the grating panels themselves, a truly comprehensive customization service from an elite manufacturer might include the seamless design and integration of ancillary FRP components such as custom-engineered handrail systems, robust ladder cages, non-slip stair treads, or even complete modular elevated platform assemblies, all fabricated from matching FRP materials to ensure absolute material compatibility and long-term performance. This holistic and integrated approach simplifies the overall procurement process for the client, reducing vendor management complexities and ensuring absolute system compatibility and optimized performance. The expert design and engineering consultation services provided by highly experienced manufacturers are exceptionally invaluable throughout this intricate process. They engage in close, collaborative partnerships with clients, conducting thorough site assessments, performing precise structural load calculations, developing detailed Computer-Aided Design (CAD) drawings, and meticulously recommending optimal resin systems, panel configurations, and installation methodologies to ensure that the ultimate FRP composite solution is not only structurally sound, maximally efficient, and perfectly fitted to the existing infrastructure but also rigorously compliant with all relevant local, national, and international safety, environmental, and industry-specific standards. This deep, consultative partnership profoundly mitigates potential project risks, significantly optimizes operational performance, and unequivocally guarantees that the substantial investment in high-quality frp micro mesh grating yields the most effective, durable, and intrinsically safe solution meticulously tailored to the project's unique operational demands, environmental conditions, and long-term safety requirements. Such an unwavering commitment to bespoke engineering, client-centric problem-solving, and precise execution clearly differentiates top-tier manufacturers, demonstrating their profound understanding of complex client needs and their proven capacity to deliver truly optimized, innovative, and enduring composite solutions.

Proven Performance: Real-World Application Case Studies and Client Successes with FRP Micro Mesh Grating

The robust theoretical advantages and compelling technical specifications of frp micro mesh grating are powerfully and empirically validated through its successful, widespread deployment in a myriad of challenging and mission-critical industrial environments across the globe. These tangible, real-world applications underscore its superior and enduring performance, its profound long-term cost-effectiveness, and its indispensable role in significantly enhancing both operational safety and continuity within demanding sectors. Consider, for instance, a major chemical processing facility strategically located in a humid coastal region. This facility was historically grappling with severe and pervasive corrosion of its traditional steel walkways, trench covers, and elevated platforms, primarily due to relentless exposure to aggressive sulfuric acid fumes, chlorine gas, and saline saltwater spray. The conventional steel gratings required annual, labor-intensive sandblasting, costly recoating, and frequent, disruptive replacement cycles, leading to exorbitant maintenance expenditures and prolonged periods of operational downtime. Upon the strategic and comprehensive transition to 1.5-inch thick frp micro mesh grating meticulously manufactured with a high-performance vinyl ester resin system, specifically engineered for extreme chemical resistance, the facility observed a truly remarkable and transformative improvement. The fine mesh pattern of the new FRP grating effectively prevented small tools, critical bolts, and other essential equipment from accidentally falling into hazardous chemical baths or delicate machinery below, dramatically improving overall site safety and preventing costly equipment damage, while the inherent and absolute corrosion resistance of the FRP eliminated the need for any routine maintenance, painting, or rust remediation. This shift reduced operational expenses by an estimated 40% within the first five years of installation, simultaneously allowing for uninterrupted and optimized production cycles. Furthermore, the significantly lightweight nature of the frp micro mesh grating profoundly simplified the installation process, accelerating the entire retrofit project by a remarkable 30% compared to previous steel replacements, minimizing disruptions to ongoing operations.

Another equally compelling and illustrative case study involved a large municipal wastewater treatment plant confronting persistent and pervasive issues with dangerously slippery surfaces and inherent electrical hazards near its pump stations, aeration basins, and clarifiers. Standard concrete walking surfaces frequently became treacherously slick with biological growth and algal accumulation, while traditional metallic grating posed unacceptable electrocution risks in close proximity to submerged electrical components and high-voltage pump motors. The strategic implementation of 1-inch thick frp micro mesh grating, featuring an integral grit surface for enhanced traction, provided exceptional and reliable slip resistance, even when thoroughly wet or covered in oily residue, thereby significantly reducing the incidence of worker accidents and injuries. Moreover, the absolute non-conductive properties of the FRP completely eliminated the critical need for complex and costly electrical grounding systems, simplifying the plant's electrical infrastructure design and profoundly enhancing overall safety for maintenance personnel working in close proximity to energized equipment and aqueous environments. The plant proudly reported an impressive 60% reduction in documented slip-and-fall incidents over a three-year period following the comprehensive installation, alongside a notable and tangible decrease in general maintenance expenditures associated with flooring, access points, and trench covers. For a massive offshore oil and gas platform, the primary and overriding concerns were profound weight reduction for enhanced structural integrity and superior resistance to the brutally corrosive marine environment. By systematically replacing heavy steel decks, walkways, and drill floor grating with remarkably lightweight frp micro mesh grating, the platform achieved a substantial and critical reduction in top-side weight, which fundamentally improved overall structural stability, reduced fatigue on the underlying steel structure, and significantly extended the operational life of the platform itself. The FRP's unwavering ability to withstand constant exposure to corrosive saltwater, intense UV radiation, extreme wind loads, and harsh weather conditions without corroding, rusting, or degrading proved absolutely invaluable, drastically cutting down on recurrent painting, cathodic protection, and rust-related repairs, leading to immense savings in labor, materials, and operational downtime. These compelling instances, drawn from typical client experiences and well-established industry benchmarks, powerfully illustrate that investing in high-quality frp micro mesh grating is not merely a procurement decision; it is a strategic and forward-thinking move towards achieving enhanced safety, substantially reduced operational costs, prolonged asset lifespan, and ultimately, superior long-term performance across the most demanding industrial applications. The authoritative data, verifiable test results, and overwhelmingly positive feedback derived from such successful projects unequivocally solidify the reputation of experienced manufacturers and underscore the intrinsic, lasting value of their advanced composite solutions.

Building Confidence: Comprehensive Quality Assurance, Dedicated Support, and FAQs for FRP Micro Mesh Grating

Trustworthiness in the highly specialized B2B composites sector is meticulously built upon an unyielding foundation of transparent processes, unwavering quality commitments, and exceptionally robust, client-centric customer support. For a critically important product like frp micro mesh grating, ensuring paramount product reliability and consistent performance begins long before the actual manufacturing process, with rigorous and multi-layered quality assurance (QA) protocols that are deeply embedded throughout the entire supply chain and every stage of the production cycle. Reputable and authoritative manufacturers implement comprehensive, multi-stage QA procedures, commencing with the meticulous inspection of all incoming raw materials—including specialized resins, continuous fiberglass rovings, and various performance-enhancing additives—to rigorously verify their precise chemical composition, critical mechanical properties, and absolute compliance with stringent procurement specifications (e.g., Certificates of Analysis, material data sheets). During the manufacturing process itself (whether sophisticated molding or advanced pultrusion), continuous in-process checks are performed to precisely monitor critical parameters such as temperature gradients, applied pressure, precise resin-to-glass ratios, and optimal curing times, utilizing cutting-edge sensors, automated control systems, and statistical process control (SPC) to maintain unwavering consistency and minimize any potential defects. Post-production, every single batch of frp micro mesh grating undergoes a comprehensive battery of final product testing. This includes meticulous dimensional checks for precision, thorough visual inspections for any surface imperfections or structural flaws, and, critically, a series of mechanical tests to empirically confirm load-bearing capacity, flexural strength (as per ASTM D790), compressive strength (as per ASTM D695), and impact resistance (as per ASTM D256). Furthermore, specialized tests for inherent fire retardancy (such as ASTM E84 for flame spread and smoke development) and long-term chemical resistance (as per ASTM C581) are systematically conducted on representative samples to absolutely ensure superior performance in the most demanding and aggressive operational environments.

Beyond rigorous product testing, a strong and unwavering emphasis on achieving and maintaining international certifications, most notably ISO 9001:2015 for Quality Management Systems, profoundly underscores a manufacturer's deep-seated commitment to operational excellence and continuous improvement. This globally recognized certification assures discerning clients that the manufacturer's internal processes are exceptionally well-defined, meticulously documented, and consistently applied to produce products of the highest quality standards. A proven service longevity in the industry, often spanning many decades, provides undeniable empirical evidence of a manufacturer's inherent reliability, market resilience, and deep industry knowledge. Strategic alliances and technical partnerships with leading engineering firms, prominent industry associations (like the American Composites Manufacturers Association - ACMA), and esteemed academic institutions further bolster a manufacturer's authority, credibility, and proactive commitment to pioneering innovation. For every project, clear, transparent, and proactive communication regarding realistic delivery schedules, typically ranging from 3-6 weeks for standard stock orders and longer for highly customized or large-volume solutions, is meticulously provided to effectively manage client expectations and facilitate seamless project planning. Crucially, a robust and explicit warranty commitment, frequently extending for several years (e.g., 5-10 years against manufacturing defects and material degradation under normal conditions), provides invaluable peace of mind and substantial protection for the client's significant capital investment. Comprehensive technical support, including detailed installation guides, best-practice maintenance recommendations, and direct, expedient access to experienced engineering experts, is readily and reliably available to assist clients throughout the entire product lifecycle, from initial concept to long-term operation. To further enhance and solidify trustworthiness, leading manufacturers frequently provide an exhaustive FAQ (Frequently Asked Questions) section, proactively addressing common queries and concerns, such as:

- What is the typical lifespan of FRP micro mesh grating in harsh environments?

With proper specification, professional manufacturing, and correct installation, high-quality frp micro mesh grating can reliably last 20-25 years or significantly more, even in highly corrosive or demanding industrial environments, substantially exceeding the operational lifespan of traditional metallic alternatives which require frequent replacement and maintenance.

- Can FRP micro mesh grating be cut on-site during installation?

Yes, frp micro mesh grating can be safely cut on-site using standard power tools equipped with specialized diamond or carbide-tipped blades. However, for utmost precision, minimized waste, and to ensure proper sealing of cut edges for maximum long-term corrosion resistance, utilizing the manufacturer's professional custom cutting and fabrication services is highly recommended.

- Is FRP micro mesh grating inherently slip-resistant, even in wet or oily conditions?

Absolutely. The vast majority of high-quality frp micro mesh grating comes standard with an expertly engineered concave or integral grit surface (e.g., quartz or silica particles embedded), providing exceptional bi-directional slip resistance, significantly reducing the risk of slips and falls even in challenging wet, oily, greasy, or icy operational conditions.

- What are the key differences between molded and pultruded FRP grating types?

Molded frp micro mesh grating offers superior bi-directional strength and excellent multi-directional corrosion resistance due to its monolithic, unitary structure. In contrast, pultruded grating provides higher uni-directional strength and stiffness, making it more suitable for applications requiring longer unsupported spans and carrying heavy loads primarily in one specific direction.

- How does FRP grating significantly contribute to enhanced workplace safety?

Its intrinsically non-conductive, non-magnetic, highly corrosion-resistant, impact-absorbent, and superior slip-resistant properties collectively and profoundly reduce a wide range of common workplace hazards. Furthermore, the fine mesh design of frp micro mesh grating specifically prevents small tools or objects from falling through to lower levels or into sensitive machinery, thereby significantly enhancing overall site safety and operational integrity.

This comprehensive and holistic approach to quality, dedicated support, and unwavering transparency collectively ensures that industrial clients not only procure a superior product but also gain a reliable, authoritative, and experienced partner who is genuinely committed to their long-term operational success, enhanced safety, and overall business prosperity.

Paving the Future: Conclusion and Outlook for FRP Micro Mesh Grating in Modern Industry

In summation, frp micro mesh grating stands as a pivotal and transformative advancement in industrial material science, offering a truly comprehensive and highly effective solution for diverse operational environments where exceptional durability, uncompromised safety, and superior long-term cost-efficiency are absolutely paramount. Its inherent and unparalleled resistance to a vast spectrum of corrosive chemicals, its absolute non-conductive properties, its remarkable strength-to-weight ratio, and its exceptional slip resistance collectively position it as an indispensable and preferred material choice for an extensive range of applications, spanning from the most aggressive and chemically challenging processing plants to high-traffic, safety-critical public walkways. The meticulous manufacturing processes employed by leading producers, coupled with rigorous, multi-stage quality control measures and unwavering adherence to stringent international standards such as ISO and ASTM, collectively ensure a finished product that not only consistently meets but frequently exceeds the performance benchmarks of traditional construction materials. Furthermore, the intrinsic ability to meticulously customize these advanced gratings to the precise project specifications, encompassing everything from specialized resin types and exact panel dimensions to specific colors and textured surface finishes, profoundly empowers engineers, architects, and procurement specialists to design truly optimized, compliant, and aesthetically integrated infrastructure solutions. The empirically demonstrated long-term performance, coupled with the tangible benefits of substantially reduced maintenance requirements, significantly enhanced operational safety, and extended asset lifespans, unequivocally underscore the profound return on investment for businesses choosing to strategically adopt this advanced composite technology. As global industries continue their relentless pursuit of sustainable, resilient, and economically viable alternatives for their ever-evolving infrastructure needs, the critical role and widespread adoption of frp micro mesh grating are poised for continuous and accelerated expansion across all sectors.

The future outlook for advanced composite materials, and particularly high-performance fiberglass gratings like frp micro mesh grating, is exceptionally promising and dynamic. This positive trajectory is powerfully driven by overarching global trends towards more sustainable and environmentally conscious construction practices, increasingly stringent and comprehensive safety regulations, and the escalating operational complexity of modern industrial facilities. Consequently, the demand for highly specialized, high-performance, and intrinsically low-maintenance materials such as FRP will only intensify. Ongoing innovations in cutting-edge resin chemistry, revolutionary fiber reinforcement technologies, and advanced manufacturing techniques (including automation and smart factories) are continuously enhancing the intrinsic properties and performance characteristics of FRP gratings, consistently pushing the boundaries of their potential applications and expanding their versatility. Emerging research into "smart composites," which incorporate embedded sensors for real-time structural health monitoring, or the development of novel self-healing resin systems, profoundly hints at the next generation of materials that will offer even greater operational intelligence, predictive maintenance capabilities, and unprecedented resilience. Furthermore, the growing global emphasis on environmental stewardship and circular economy principles will likely accelerate the adoption of materials with lower embodied carbon footprints during manufacturing and demonstrably longer service lives, thereby significantly reducing waste generation and optimizing resource consumption throughout the material's lifecycle. For discerning B2B decision-makers, staying consistently abreast of these groundbreaking advancements and proactively partnering with manufacturers who are demonstrably at the forefront of innovation is absolutely crucial for maintaining a significant competitive edge and ensuring that their critical infrastructure remains robust, intrinsically safe, highly efficient, and comprehensively future-proof. The strategic integration of cutting-edge solutions like the Holiday Special Offers GRP FRP Gratings Fiberglass Grates not only signifies a profound commitment to leveraging advanced material science for enduring operational excellence but also positions an enterprise as a leader in adopting sustainable and safe industrial practices for decades to come.

References and Further Reading:

- American Composites Manufacturers Association (ACMA) - https://acmanet.org/ (Provides comprehensive industry trends, technical standards, and best practices in composites manufacturing and applications.)

- Composites World Magazine - https://www.compositesworld.com/ (A leading publication offering in-depth technical articles, market insights, and news on advanced composite materials and technologies.)

- ASTM International Standards - https://www.astm.org/ (The authoritative source for internationally recognized material testing and performance standards, including specific standards for FRP products like D790, D638, E84, and C581.)

- National Fire Protection Association (NFPA) - https://www.nfpa.org/ (Offers codes and standards relevant to fire safety, particularly applicable to phenolic FRP grating in certain industrial settings.)

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025