loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

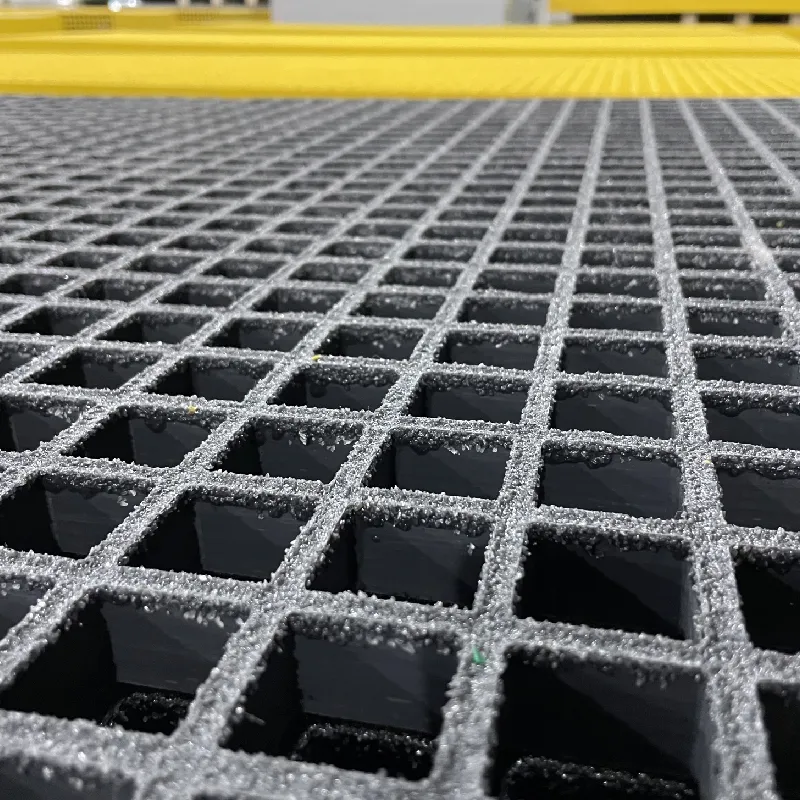

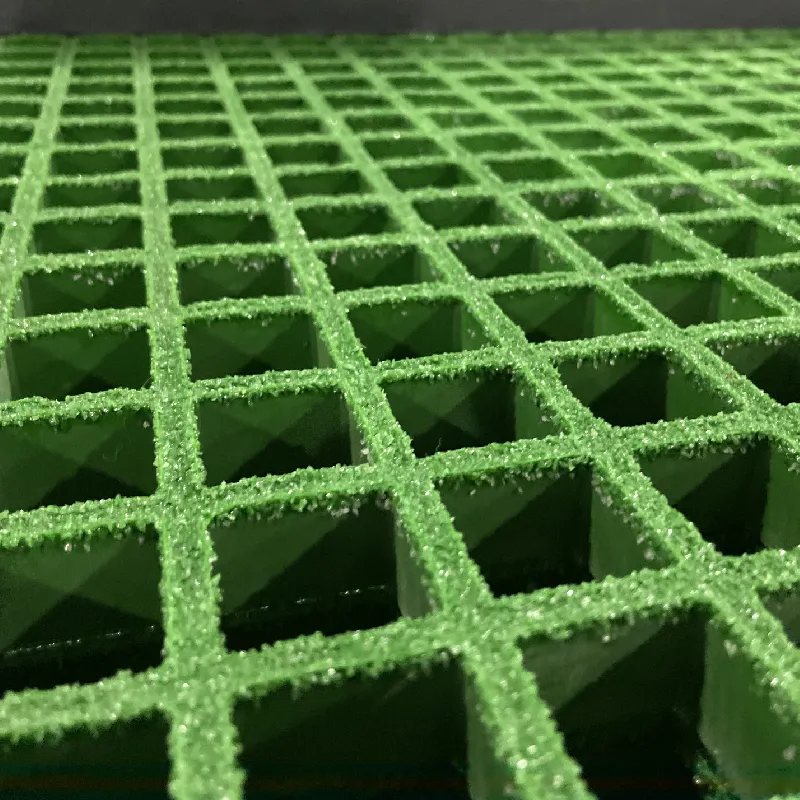

FRP Micro Mesh Grating – Anti-Slip, Corrosion-Resistant

A Field Insider’s Take on FRP Micro Mesh Grating: What’s Real, What’s Hype

If you’ve walked a wastewater deck or a salty marina lately, you’ve probably already stood on frp micro mesh grating without noticing. And that’s the point: it quietly solves corrosion, slippage, and maintenance headaches. ZJ Composites’ “Holiday Special Offers GRP FRP Gratings Fiberglass Grates” line—made in No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China—leans into that simplicity with standard, mini, and micro mesh options.

Why micro mesh, and why now?

Industry trend? Tighter apertures. That’s because micro mesh reduces dropped-object risk, supports small-wheeled carts (even high-heel safe, as a plant manager once joked), and improves debris control versus open grating. Many customers say the biggest surprise is not the weight savings—it’s the noticeably lower slip risk in wet, oily areas. To be honest, I was skeptical too, until I saw incident reports flatten after a switch to frp micro mesh grating on a coastal pump station.

Process, materials, and testing (no fluff)

- Resin systems: isophthalic or vinyl ester (for aggressive chemicals); UV inhibitors + fire-retardant additives.

- Reinforcement: E-glass roving + surface veil for corrosion barrier.

- Method: typically molded panels with an integrated micro-mesh overlay; cured under controlled temperature; edges sealed.

- Finish: silica-grit anti-slip top; conductive options available on request.

- Quality/Testing: ASTM D790 flexural, ASTM D2583 Barcol hardness, ASTM E84 flame spread, ASTM C581 chemical resistance; slip tests and UV aging (ASTM G154).

- Expected service life: ≈25–30 years in normal industrial exposure (real-world use may vary).

Typical product specifications

| Parameter | Value (≈) |

|---|---|

| Panel thickness | 25–38 mm |

| Mesh aperture | ≈12×12 mm micro mesh |

| Flexural strength (ASTM D790) | ≥200 MPa panel average |

| Flame spread (ASTM E84) | FSI ≤25 (FR resin) |

| Slip resistance (COF) | Dry ≈0.70; Wet ≈0.55 |

| Barcol hardness (ASTM D2583) | 35–45 |

| Certifications | OSHA 1910 compliance for walking surfaces; ISO/EN guidance as applicable |

Where it fits

Use frp micro mesh grating in wastewater plants, chemical processing, offshore platforms, power stations, pulp & paper, food & beverage (non-conductive, corrosion-resistant), and municipal walkways/ramps. It’s light enough to install without hot works, which saves time and permits—contractors love that.

Vendor snapshot (quick reality check)

| Vendor | Certs/Tests | Lead Time | Customization | Price (≈) | Notes |

|---|---|---|---|---|---|

| ZJ Composites | ASTM/OSHA-aligned; FR resins | 2–4 wks | Sizes, colors, resin, grit | $$ | Strong value/lead times |

| Generic Steel Fabricator | EN/ASTM for steel | 3–6 wks | Coatings, thickness | $ | Low cost; high maintenance |

| Other FRP Brand (Overseas) | Varies | 6–10 wks | Limited | $$$ | Longer freight/uncertainty |

Customization options

Panel size up to large formats; thickness 25–38 mm; resin (ISO/Vinyl Ester); color (grey, green, yellow); anti-static; edge banding; load rating per span; pre-cut kits for platforms and trenches. I guess the most requested tweak lately is conductive grits for explosive zones.

Mini case notes (from the field)

- Coastal wastewater plant: replacing corroded steel with frp micro mesh grating cut maintenance hours by ≈40% over 18 months; slip events dropped to zero.

- Offshore service deck: micro mesh aperture prevented fastener drop-throughs; recorded a 60% reduction in near-miss reports, according to the HSE log.

Bottom line: it’s not just lighter—it’s safer, quieter underfoot, and, surprisingly, kinder to OPEX. If you care about lifecycle cost, this is worth a hard look.

References

- ASTM D790 – Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials

- ASTM C581 – Standard Practice for Determining Chemical Resistance of FRP

- ASTM D2583 – Standard Test Method for Indentation Hardness of Rigid Plastics by Barcol Impressor

- OSHA 29 CFR 1910 Subpart D – Walking-Working Surfaces (e.g., 1910.22)

- ASTM G154 – Standard Practice for UV Exposure of Nonmetallic Materials

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025