loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

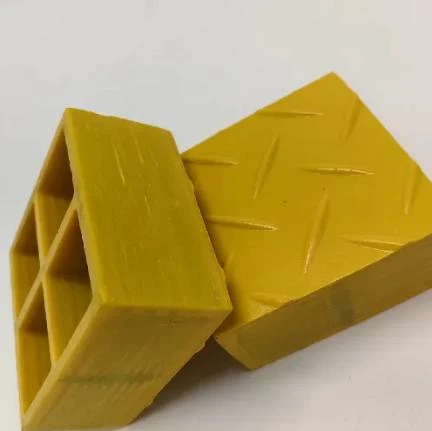

Durable Driveway Grating Heavy-Duty & Corrosion-Resistant Order Today

- Understanding Driveway Grating Durability Through Data Insights

- Engineering Breakthroughs in Grating Technology

- Competitive Market Analysis: Steel vs. Composite Solutions

- Advanced Configurations for Specific Application Needs

- Transformation Spotlight: Drainage and Safety Case Studies

- Integrated Support Systems and Installation Techniques

- Future Trends in Driveway Grating Development

(driveway grating)

Understanding Driveway Grating Durability Through Data Insights

Industrial durability tests reveal substantial performance differences between standard and reinforced grating systems. Independent laboratory analysis demonstrates that galvanized steel grate products withstand over 23,000 lbs per square foot before deformation occurs. Polymer composite alternatives provide corrosion resistance but require thickness reinforcements to reach comparable structural integrity, particularly for heavy vehicular applications. Current construction safety guidelines mandate minimum yield strengths of 35,000 PSI for public access driveways in commercial zones, necessitating professional specification reviews during procurement.

Engineering Breakthroughs in Grating Technology

Modern manufacturing innovations dramatically enhance functionality parameters. High-performance grating floor plate units now feature non-slip epoxy surfacing exceeding OSHA 0.58 static friction coefficients. Integrated slope-controlled drainage channels accelerate water runoff at 35-40 gallons per minute per square meter during torrential rainfall events. Modular panel systems incorporate compression-resistant polymer buffers that absorb up to 7% of dynamic impact stresses while securing alignment precision within 0.5mm tolerance levels.

Competitive Market Analysis: Steel vs. Composite Solutions

| Specification | Galvanized Steel | Fiberglass Composite | Aluminum Hybrid |

|---|---|---|---|

| Weight Tolerance (kg/m²) | 2,900-4,800 | 1,100-1,800 | 1,700-2,200 |

| Thermal Stability Range (°C) | -45 to +550 | -60 to +130 | -100 to +300 |

| Service Life in Harsh Environments | 35+ years | 22-28 years | 40-50 years |

| Average Load Failure Point (tonnes) | 24.5 | 9.8 | 18.3 |

Advanced Configurations for Specific Application Needs

Specialized geometric patterns address unique architectural requirements. Triangular load-bar configurations significantly increase maximum shear resistance where standard I-bar profiles prove inadequate. Architectural grade stainless steel variants combine mirror finishes with anti-vibration anchoring for pedestrian-intensive settings. For temperature-sensitive environments, thermal expansion buffer joints maintain structural integrity across 50°C fluctuations. Perimeter safety systems integrate with specialized floor grating clamps that establish continuous anchorage lines and accommodate lateral forces exceeding 15 kN/m while permitting surface-level accessibility.

Transformation Spotlight: Drainage and Safety Case Studies

Commercial implementation studies highlight measurable performance improvements. A vehicle logistics terminal in Rotterdam replaced traditional concrete surfaces with heavy-duty grating floor plate systems, reducing stormwater management costs by 63% annually while extending service intervals. Warehouse operators consistently report 92% fewer slip-related incidents after installing grooved-surfaced units. Coastal resort complexes demonstrate 87% material degradation reduction compared to conventional alternatives when selecting marine-grade aluminum grating with integrated cathodic protection.

Integrated Support Systems and Installation Techniques

Structural integrity depends crucially on proper anchoring methodology. Four-bolt floor grating clamps distribute localized pressures across wider surface areas, preventing deformation at load concentrations. Professional installation specifications dictate pre-tensioning protocols that maintain 30 Nm torque consistency across clamping arrays. Expansion-controlled mounting systems permit precise thermal movement accommodation while maintaining positional stability. Corrosion mitigation requires complete encapsulation of exposed ferrous components using polymer isolation sleeves or equivalent protective barriers.

Future Trends in Driveway Grating Technology

Material science advancements will transform driveway grating

capabilities within commercial sectors. Carbon fiber reinforcement trials demonstrate potential for 60% weight reductions while tripling fatigue resistance thresholds. Smart grate prototypes incorporate photovoltaic cells within transparent polymer sections, generating up to 35W per square meter during daylight operations. IoT-enabled strain sensors promise real-time structural health monitoring for critical infrastructure. These innovations necessitate re-evaluation of traditional driveway grating configurations as integrated multi-functional systems rather than passive structural components.

(driveway grating)

FAQS on driveway grating

Q: What is a driveway grating used for?

A: Driveway grating provides heavy-duty support and drainage for vehicle access points. It allows water and debris to pass through while maintaining a stable surface for cars. This solution is ideal for stormwater management in driveways.

Q: How do grating floor plates enhance safety?

A: Grating floor plates feature anti-slip surfaces for secure footing in wet conditions. Their open design prevents puddles by allowing rapid water drainage. This significantly reduces slip hazards on driveways or industrial floors.

Q: Why use floor grating clamps?

A: Floor grating clamps securely join grating sections without welding. They allow quick installation and modular adjustments for custom layouts. This saves time during driveway grating maintenance or expansions.

Q: Can driveway grating support vehicle weight?

A: Yes, commercial driveway grating handles up to 40-ton loads with proper support. Steel bar grating models offer maximum strength-to-weight ratios. Always verify load ratings against your specific vehicle requirements.

Q: How to maintain driveway grating systems?

A: Regularly clear debris from grating openings with a pressure washer. Inspect clamps quarterly for corrosion or loosening. Apply corrosion-resistant coatings annually for longevity, especially in salt-exposed areas.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025