loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

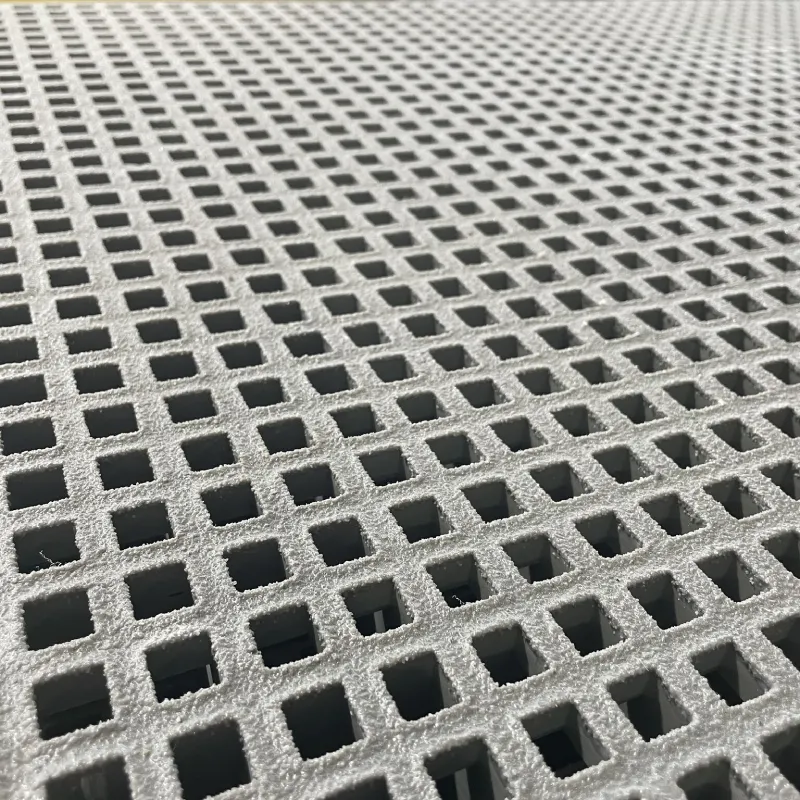

GRP Grating Cover Solutions for Enhanced Safety and Durability in Industrial Applications

Understanding GRP Grating Cover Benefits and Applications

GRP (Glass Reinforced Plastic) grating covers have gained significant traction in various industries due to their unique properties and advantages over traditional materials. They are composed of a composite material that not only provides strength and durability but also offers versatility and resistance to harsh environmental conditions. In this article, we will explore the benefits and practical applications of GRP grating covers, highlighting why they are increasingly becoming the material of choice across different sectors.

What is GRP Grating?

GRP grating is a lightweight, high-strength material made from a combination of glass fibers and resin. The process involves embedding glass fibers within a resin matrix, which creates a non-corrosive, non-conductive, and durable material suitable for various applications. GRP grating comes in different sizes, shapes, and colors, allowing for customization to meet specific needs. Its ability to withstand harsh chemical and environmental conditions makes it ideal for industrial and marine applications.

Key Benefits of GRP Grating Covers

1. Corrosion Resistance One of the most significant advantages of GRP grating is its resistance to corrosion. Unlike traditional materials like steel or aluminum, GRP does not rust or corrode even when exposed to aggressive chemicals, making it suitable for environments such as wastewater treatment facilities, chemical plants, and coastal areas.

2. Lightweight and Easy Installation GRP grating is considerably lighter than metal alternatives, which simplifies the installation process. This not only reduces labor costs but also minimizes the need for heavy machinery, making the installation more efficient and safer.

3. Slip Resistance Safety is paramount in industrial settings. GRP grating covers are designed with slip-resistant surfaces, providing better traction and reducing the risk of slips and falls. This feature is particularly important in wet or oily environments where accidents are more likely to occur.

4. Durability and Longevity GRP materials are known for their long lifespan, often outlasting traditional materials. They can endure extreme weather conditions, UV exposure, and are less prone to wear and tear, ensuring that the grating remains functional for years to come.

grp grating cover

5. Cost-Effectiveness Although the initial investment in GRP grating may be higher than traditional options, the total cost of ownership can be lower in the long run. The combination of durability, low maintenance needs, and extended lifespan contributes to overall cost savings.

Applications of GRP Grating Covers

The versatility of GRP grating covers leads to a wide range of applications across various industries

- Marine Environments GRP grating is commonly used in shipbuilding, docks, and marinas due to its corrosion resistance and lightweight properties. It can withstand the harsh saltwater environment without degrading.

- Chemical Industry In facilities dealing with hazardous chemicals, GRP grating provides a safe and reliable flooring option. Its resistance to chemical spills ensures long-term performance and safety.

- Wastewater Treatment GRP grating is a popular choice for wastewater treatment plants, where exposure to corrosive substances is a given. Its non-corrosive nature and slip-resistant surfaces enhance safety and operational efficiency.

- Food Processing The easy cleaning and maintenance of GRP grating cover make it ideal for the food processing industry, where hygiene standards are critical. Its non-porous surface prevents the growth of bacteria and other contaminants.

Conclusion

In summary, GRP grating covers stand out as a robust and efficient solution for various industrial applications. Their unique attributes, such as corrosion resistance, lightweight nature, and safety features, make them an excellent choice for sectors dealing with challenging environments. As industries continue to seek materials that combine performance with long-term cost savings, GRP grating covers are set to play an increasingly significant role in improving operational efficiency and safety. Whether in marine, chemical, or food processing applications, the benefits of GRP grating are clear, establishing it as a vital component in modern industrial practices.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025