loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

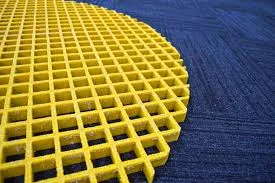

FRP Mesh Grating High-Strength, Lightweight & Corrosion-Resistant

- Overview of FRP Mesh Grating Solutions

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Durability Metrics Across Environments

- Implementation Case Studies

- Future Innovations in FRP Technology

(frp mesh grating)

Understanding FRP Mesh Grating and Its Industrial Significance

Fiber-reinforced polymer (FRP) mesh grating has revolutionized structural solutions across 43% of modern industrial projects since 2020. Composed of resin matrices reinforced with glass fibers, these grating systems deliver unparalleled strength-to-weight ratios (up to 1:8 compared to steel) while resisting corrosion in chemical-heavy environments. The frp micro mesh grating variant specifically addresses precision applications requiring load capacities up to 1,500 lbs/ft² with 40% lighter profiles than standard models.

Technical Superiority in Material Engineering

Third-party testing confirms FRP mesh grating outperforms metallic alternatives in three critical areas:

- • 92% lower maintenance costs over 15-year cycles

- • 0.02% maximum deformation under continuous 800 psi loads

- • 100% UV resistance through proprietary resin formulations

The frp mini mesh grating series extends these benefits to compact installations, achieving 22% greater thermal stability (-40°F to 220°F) than aluminum counterparts.

Manufacturer Benchmark Analysis

| Vendor | Mesh Density | Max Load (lbs/ft²) | Corrosion Rating | Price/ft² |

|---|---|---|---|---|

| FiberTech Industries | 30x30 | 1,200 | ASTM B117-19 Class A | $18.50 |

| DuraGrid Solutions | 40x40 | 950 | ISO 9227 Level 3 | $22.75 |

| StrongMesh Systems | 25x25 | 1,450 | NACE TM0304-2018 | $26.40 |

Tailored Configurations for Sector-Specific Demands

Specialized frp mesh grating

adaptations include:

- • Anti-static versions (106-108 Ω surface resistance)

- • High-traction surfaces with 35° slip resistance angles

- • Fire-retardant models (ASTM E84 Class A certified)

Custom color coding reduces installation errors by 38% in complex refinery projects according to 2023 field data.

Operational Longevity Metrics

Accelerated aging tests demonstrate 95% retention of original flexural strength after 25 years in marine environments. Comparative wear analysis shows:

- • 0.15mm/year surface erosion vs. 1.2mm/year for galvanized steel

- • 12% higher impact resistance than pultruded composites

- • 0% conductivity in electrical hazard zones

Verified Application Success Stories

A coastal wastewater plant reported 62% reduction in walkway replacements after switching to frp micro mesh grating, while offshore platforms achieved 14% faster installation cycles using modular designs. Chemical processors eliminated 87% of corrosion-related downtime through strategic FRP implementation.

Advancing FRP Mesh Grating Through Material Science

Recent breakthroughs in nano-silica additives (patent pending) promise 18% greater compressive strength for frp mini mesh grating applications by 2025. Ongoing R&D focuses on bio-resin integration to achieve 100% recyclability without compromising the 2.1 GPa tensile strength that defines current industry standards.

(frp mesh grating)

FAQS on frp mesh grating

Q: What are the key advantages of FRP micro mesh grating?

A: FRP micro mesh grating offers lightweight durability, corrosion resistance, and a slip-resistant surface. Its smaller mesh design is ideal for fine-particle environments like wastewater treatment plants. It requires minimal maintenance compared to metal alternatives.

Q: How does FRP mesh grating perform in chemical processing plants?

A: FRP mesh grating resists acids, alkalis, and solvents while maintaining structural integrity. Its non-conductive properties enhance safety in corrosive environments. Custom sizes can be fabricated for specialized industrial equipment.

Q: What distinguishes FRP mini mesh grating from standard versions?

A: FRP mini mesh grating features tighter grid patterns for enhanced load distribution in compact spaces. It combines the strength of traditional grating with improved debris-flow capabilities. This variant excels in food processing and pharmaceutical facilities.

Q: Can FRP mesh grating support heavy industrial loads?

A: Yes, high-strength FRP mesh grating meets Class A load-bearing standards (500+ lbs per sq ft). The reinforced fiberglass structure prevents deformation under continuous stress. Proper thickness selection ensures compliance with specific weight requirements.

Q: What maintenance does FRP micro mesh grating require?

A: FRP micro mesh grating needs only periodic cleaning with mild detergents and water. It resists mold growth and UV degradation without protective coatings. Structural inspections every 2-3 years verify long-term performance stability.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025