loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Guide to Various CHS Tube Size Specifications and Their Applications

Understanding CHS Tube Sizes A Comprehensive Overview

When it comes to structural engineering and construction, the choice of materials plays a crucial role in the integrity and performance of a project. One of the essential materials used in various construction applications is the Circular Hollow Section (CHS) tube. Understanding CHS tube sizes is vital for professionals in the industry, as it influences structural design, load-bearing capabilities, and overall project feasibility. In this article, we will explore the different aspects of CHS tube sizes, including their dimensions, applications, and key considerations when selecting them.

What are CHS Tubes?

Circular Hollow Sections (CHS) are steel tubes characterized by their circular cross-section. They are widely used in construction due to their strength, versatility, and aesthetic appeal. CHS tubes are manufactured in various sizes to accommodate different structural requirements. Common materials for CHS tubes include mild steel, stainless steel, and other alloys, allowing them to be suitable for numerous applications, including buildings, bridges, and industrial structures.

Standard CHS Tube Sizes

CHS tubes are available in a variety of standard sizes defined by their external diameter (OD) and wall thickness. The external diameter is a crucial specification as it directly influences the structural capacity of the tube. Commonly, CHS tubes are categorized by nominal sizes, which denote the approximate external diameter.

The following are typical nominal sizes for CHS tubes

- Diameter The most common diameters range from 20 mm to 600 mm. - Wall Thickness Wall thickness usually varies from 1.6 mm to 16 mm, depending on the required strength and structural load.

CHS tubes are typically specified in terms of both their nominal diameter and wall thickness. For example, a tube might be referred to as 100x5 CHS, indicating a 100 mm outer diameter with a wall thickness of 5 mm.

Applications of CHS Tubes

CHS tubes are favored in several applications due to their unique properties

chs tube sizes

1. Structural Support Their high strength-to-weight ratio makes CHS tubes ideal for use in beams, columns, and trusses in various structures. 2. Architecture and Design Architects often choose CHS tubes for aesthetic reasons, as their smooth, circular appearance adds modernity to building designs.

3. Transport and Distribution CHS tubes are employed in the construction of frameworks for trucks, trailers, and other transportation equipment, ensuring robust structural support.

4. Industrial Structures Many industrial applications utilize CHS tubes for frames, racks, and supports, particularly in manufacturing and warehousing.

Key Considerations for Selecting CHS Tube Sizes

When choosing CHS tube sizes for a project, several factors must be considered

1. Load Requirements Understanding the loads the structure will need to support is crucial. This includes dead loads (weight of the structure itself), live loads (weight of occupants and movable objects), and environmental loads (wind, snow, etc.).

2. Design Specifications Local building codes and design specifications must be adhered to, ensuring that the selected CHS tubes meet all regulatory requirements.

3. Material Types Depending on the environment and application, the choice of material can affect the durability and performance of CHS tubes. For example, stainless steel is preferred in corrosive environments.

4. Cost Efficiency Balancing performance with budget constraints is critical. An oversized tube may offer better strength, but at a higher cost, impacting overall project finances.

Conclusion

In conclusion, understanding CHS tube sizes is essential for engineers, architects, and builders involved in construction projects. The right choice of CHS tubes not only enhances the strength and stability of structures but also contributes to the aesthetic value of architectural designs. By considering key factors such as load requirements, material types, and cost, professionals can make informed decisions that lead to successful project outcomes. As construction methods and materials continue to evolve, staying updated on CHS standards and specifications will ensure that future projects meet both safety and aesthetic standards effectively.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

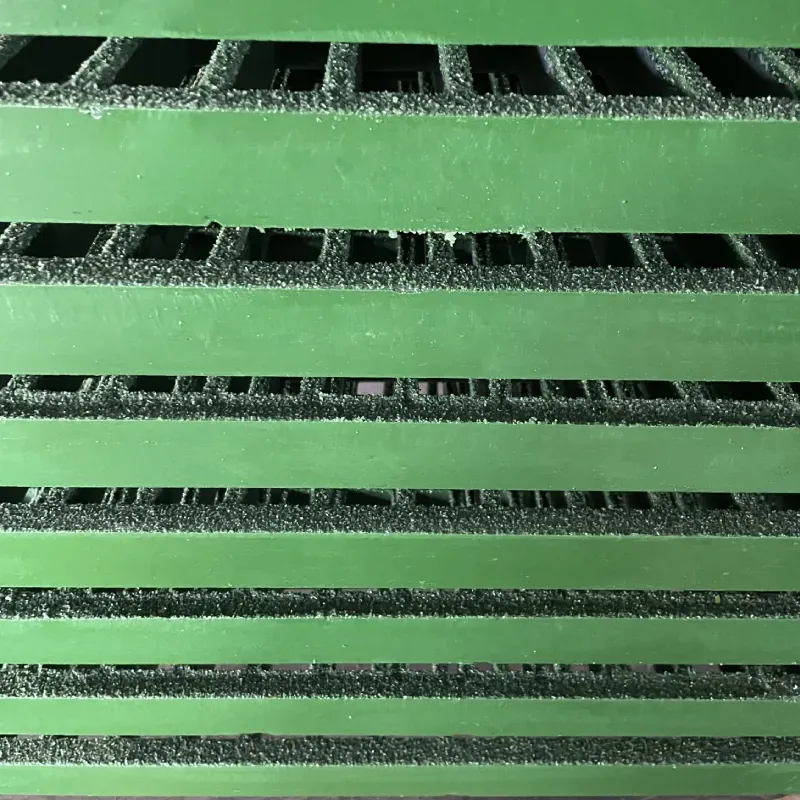

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025