loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Xan . 09, 2025 10:39

Back to list

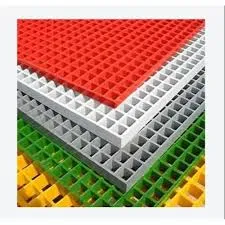

Anti- Corrosion Cost Effective FRP Pultrusion Grating

As the industrial landscape evolves, materials that offer superior strength, durability, and resistance to harsh conditions are in high demand. Pultruded FRP (Fiber Reinforced Polymer) grating stands out as a top contender in this category, showcasing a perfect blend of innovation and practicality that appeals to industries requiring high-performance solutions.

Professional engineers and industry experts advocate pultruded FRP grating for its versatile applications and adaptability to diverse working conditions. According to engineering reviews, the customization possibilities available with pultruded FRP grating allow precise adaptations to project specifications, with bespoke color, size, and resin formulations to suit specific conditions and aesthetic preferences. Trust in pultruded FRP grating stems from extensive testing and validation, underscored by its certifications from internationally recognized bodies such as ISO and ASTM. These certifications offer assurance regarding the material’s adherence to global safety and quality standards. Meanwhile, documented case studies highlight its successful deployment in numerous projects globally, further enhancing its reputation for trustworthiness in challenging environments. Innovative applications of pultruded FRP grating extend beyond traditional industrial uses. It's increasingly being employed in modern architectural projects, where its aesthetic flexibility and structural integrity contribute to sustainable building practices. Its application in eco-friendly designs aims to minimize environmental impact without sacrificing durability or safety, aligning with global sustainability initiatives. In conclusion, pultruded FRP grating emerges as a forward-thinking solution reconciling environmental demands with industrial robustness. Its unique production process, coupled with exceptional mechanical properties, offers an authoritative option for industries demanding both performance and compliance. As industries pivot towards sustainable and resilient materials, pultruded FRP grating stands at the forefront, supported by a steadfast reputation for quality, expertise, and trustworthiness.

Professional engineers and industry experts advocate pultruded FRP grating for its versatile applications and adaptability to diverse working conditions. According to engineering reviews, the customization possibilities available with pultruded FRP grating allow precise adaptations to project specifications, with bespoke color, size, and resin formulations to suit specific conditions and aesthetic preferences. Trust in pultruded FRP grating stems from extensive testing and validation, underscored by its certifications from internationally recognized bodies such as ISO and ASTM. These certifications offer assurance regarding the material’s adherence to global safety and quality standards. Meanwhile, documented case studies highlight its successful deployment in numerous projects globally, further enhancing its reputation for trustworthiness in challenging environments. Innovative applications of pultruded FRP grating extend beyond traditional industrial uses. It's increasingly being employed in modern architectural projects, where its aesthetic flexibility and structural integrity contribute to sustainable building practices. Its application in eco-friendly designs aims to minimize environmental impact without sacrificing durability or safety, aligning with global sustainability initiatives. In conclusion, pultruded FRP grating emerges as a forward-thinking solution reconciling environmental demands with industrial robustness. Its unique production process, coupled with exceptional mechanical properties, offers an authoritative option for industries demanding both performance and compliance. As industries pivot towards sustainable and resilient materials, pultruded FRP grating stands at the forefront, supported by a steadfast reputation for quality, expertise, and trustworthiness.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025