loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Mini Mesh Grating - Anti-Slip, Corrosion-Resistant FRP/GRP

Smaller Open Mesh Area FRP Mini Mesh Grating — field notes from the waterfront

If you spend time around marinas or wastewater decks (I do, probably more than is healthy), you’ve seen the quiet rise of Mini Mesh Grating. It’s FRP, it’s heel-safe, and it doesn’t throw tantrums in salt spray. ZJ Composites’ Smaller Open Mesh Area FRP option comes out of Hebei, China, and—honestly—has been a solid performer on docks and ramps where timber fails fast and aluminum gets slippery.

Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

What it is (and why the industry cares)

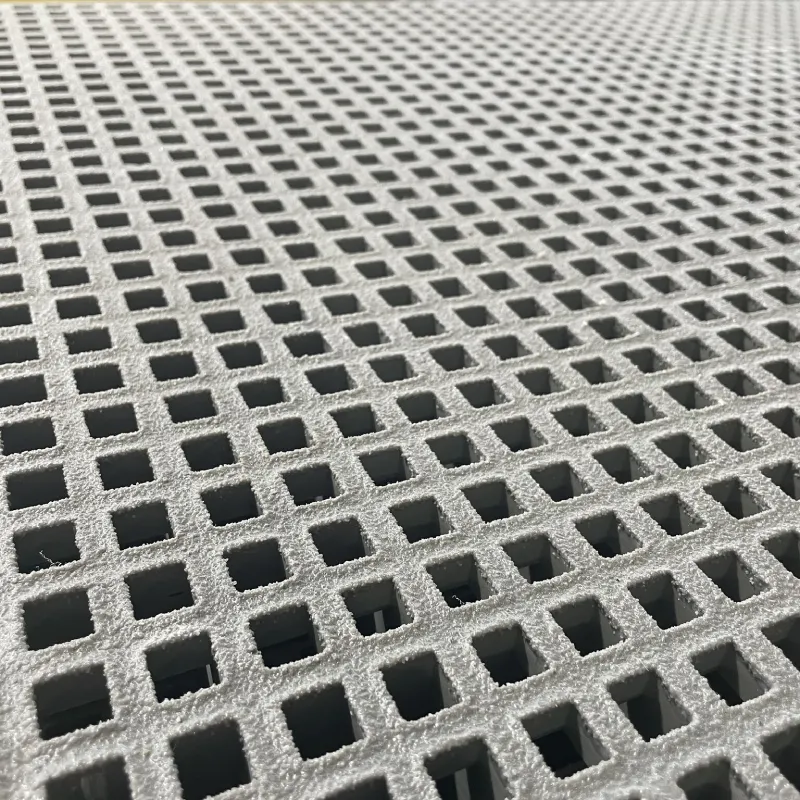

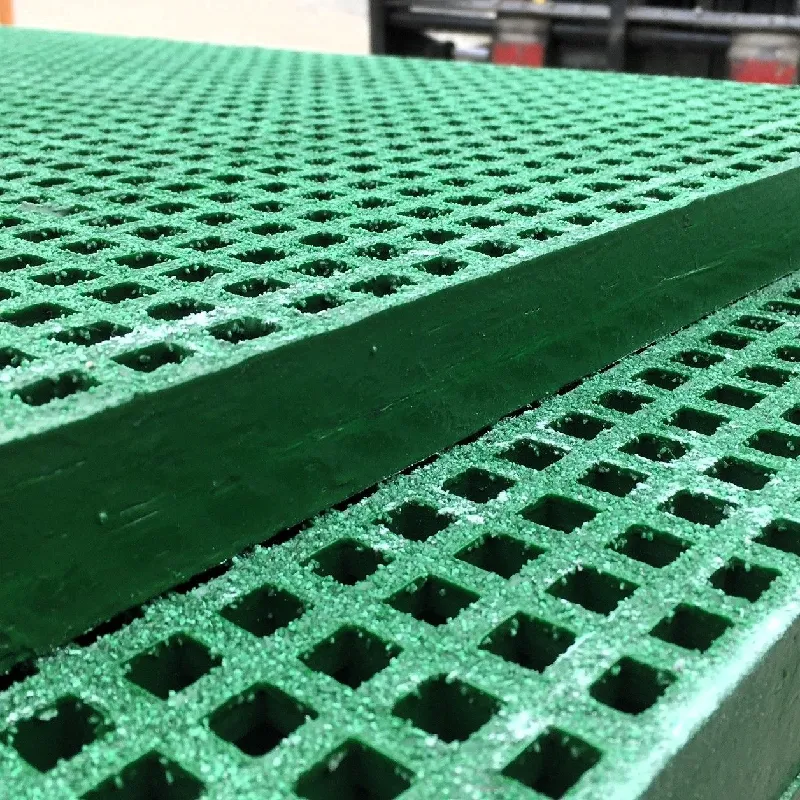

FRP molded panels with a tighter lattice reduce fall-through risk and heel catch; that’s the “mini” in Mini Mesh Grating. The trend? Longer lifecycle assets, lower maintenance, and better slip resistance—especially where algae and diesel sheen gang up on you. Many customers say the grit topcoat is the difference between a close call and a safe shift.

Typical specifications (real-world use may vary)

| Parameter | Typical Value ≈ | Notes |

|---|---|---|

| Mesh opening | 12–13 mm square | Heel-safe; ADA-oriented openings |

| Panel thickness | 25–38 mm | Load class depends on thickness |

| Resin options | Isophthalic / Vinyl Ester | Fire-retardant and UV-inhibited grades available |

| Flexural strength | ≈ 200–300 MPa | ASTM D790 tested |

| Slip resistance (wet) | PTV 55–65 | With grit; AS/NZS 4586 P5 category |

| Flame spread index | ≤ 25 (Class A) | ASTM E84 with FR resin system |

| Service life | 25–30+ years | Corrosive environments included |

Process, QC and testing (short version)

Materials: E-glass rovings + thermoset resin (isophthalic or vinyl ester), pigments, UV inhibitors, grit aggregate. Method: molded FRP (wet layup in a heated mold), cured, demolded, edges trimmed, grit applied. Testing: flexural (ASTM D790), burn rate (ASTM D635), surface burning (ASTM E84), chemical resistance screening (ASTM D543), slip test (AS/NZS 4586 or pendulum equivalents). I like to see panel proof-load tests plus QC on bar-to-bar bond integrity.

Where it excels

- Marine piers, docks, gangways, ramps (salt + splash zones)

- Wastewater treatment walkways and clarifier bridges

- Chemical plants and refineries (acid/alkali exposure)

- Rooftop access paths, cooling towers, public boardwalks

Advantages: corrosion resistance, non-conductive, lighter than steel, stable slip resistance, and—surprisingly—less glare than aluminum decks. The tighter lattice of Mini Mesh Grating also reduces dropped tool incidents.

Vendor snapshot (my quick, imperfect comparison)

| Vendor | Material/Resin | Corrosion | Slip (wet) | Weight | Certs/Standards | Lead Time |

|---|---|---|---|---|---|---|

| ZJ Composites (this product) | Molded FRP, Iso/VE | High (marine-grade) | PTV 55–65 (P5) | Light | ASTM D790/E84, AS/NZS 4586 | Around 2–4 weeks |

| Generic FRP Vendor A | Molded FRP, Iso | Moderate–High | PTV ≈ 50–60 | Light | ASTM D790 | 3–6 weeks |

| Aluminum Vendor B | 5052/6061 | Good (not for chlorides) | Lower without coatings | Very Light | ASTM B221 | 1–3 weeks |

Customization

Panel sizes cut-to-fit, edge banding, grit grades (fine to heavy), color coding for zones, conductive-safe options (where needed), and resin upgrades for solvent exposure. For public spaces, specify flame-retardant vinyl ester to keep Mini Mesh Grating in Class A per E84.

Mini case study: marina retrofit

A 180 m public marina replaced aging timber with Mini Mesh Grating in a grit P5 finish. Post-install feedback (six months): slip incidents fell to zero; crews liked the underfoot “quiet” feel; inspectors noted better light penetration for eelgrass. Spot tests showed wet PTV 58–61 and no measurable corrosion; honestly, that’s about as uneventful (in a good way) as it gets. Maintenance budget was revised down by ~28%.

Final thought: in salty, chemical, or relentlessly wet sites, FRP mini-mesh isn’t just a material—it’s a peace-of-mind line item.

Authoritative references

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025