loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp grating platform

Understanding the FRP Grating Platform Characteristics, Advantages, and Applications

Fiber Reinforced Polymer (FRP) grating platforms have emerged as a vital solution in various industrial applications, providing a robust alternative to traditional materials such as steel and aluminum. This innovative technology is increasingly utilized in environments where strength, durability, and safety are paramount. This article delves into the characteristics, advantages, and diverse applications of FRP grating platforms.

Characteristics of FRP Grating Platforms

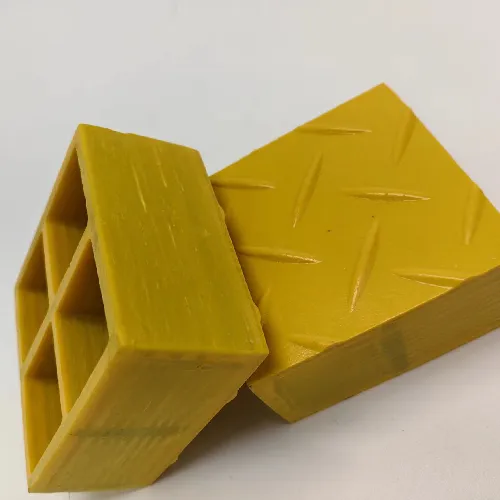

FRP grating platforms are made from a composite material that combines a polymer matrix reinforced with fibers, typically made of glass or carbon. This composition endows the grating with remarkable physical and chemical properties. One of the primary characteristics of FRP grating is its lightweight nature. Compared to traditional steel grating, FRP is significantly lighter, reducing the overall load on structures and making transportation and installation more manageable.

Additionally, FRP grating exhibits excellent corrosion resistance. It performs exceptionally well in harsh environments, such as those involving exposure to chemicals, saltwater, and extreme temperatures. This characteristic extends the lifespan of the grating platforms, minimizing the need for frequent replacements and reducing maintenance costs over time.

Another notable feature is the high non-slip surface, which enhances safety in both wet and dry environments. The grating is designed with a textured surface that provides excellent traction, reducing the risk of slips and falls in industrial settings.

Advantages of FRP Grating Platforms

The advantages of using FRP grating platforms are numerous and impactful. Firstly, their lightweight yet strong construction leads to lower installation costs. Since they are easier to handle and install, projects can be completed faster, yielding considerable savings in labor.

frp grating platform

Cost-effectiveness is another key advantage. Although the initial investment in FRP grating can be higher than that of traditional materials, the long-term savings on maintenance and replacement overshadow these costs. Their resistance to corrosion means they do not require regular painting or treatment, which can significantly reduce upkeep expenditures.

Moreover, FRP grating platforms are environmentally friendly. The production of these materials often involves less energy consumption compared to that of metal alternatives. Additionally, they can be recycled, thus minimizing waste and promoting sustainable practices in construction and industrial applications.

Applications of FRP Grating Platforms

FRP grating platforms find diverse applications across many sectors. In the chemical industry, their resistance to corrosive substances makes them indispensable in factories and processing plants. They are also widely used in the wastewater treatment sector, where the grating can withstand exposure to harsh chemicals and environments.

Additionally, FRP gratings are commonly employed in marine applications, including docks and piers, due to their durability against saltwater corrosion and their lightweight nature, which facilitates easier installation and maintenance. In the oil and gas sector, these platforms provide safe walking surfaces in drilling and production facilities, ensuring worker safety in potentially hazardous environments.

Furthermore, they are increasingly utilized in pedestrian walkways, bridges, and even in recreational areas like parks and sports fields. Their versatility and adaptability make them suitable for a wide range of settings, enhancing both functionality and aesthetics.

Conclusion

In conclusion, FRP grating platforms represent a significant advancement in material technology, offering numerous benefits that make them an attractive choice for various industrial and commercial applications. Their lightweight, corrosion-resistant nature and non-slip properties contribute to enhanced safety and durability, allowing them to meet the rigorous demands of modern infrastructure. As industries continue to seek sustainable and cost-effective solutions, FRP grating platforms are poised to play an increasingly important role in the future of construction and maintenance.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025