loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

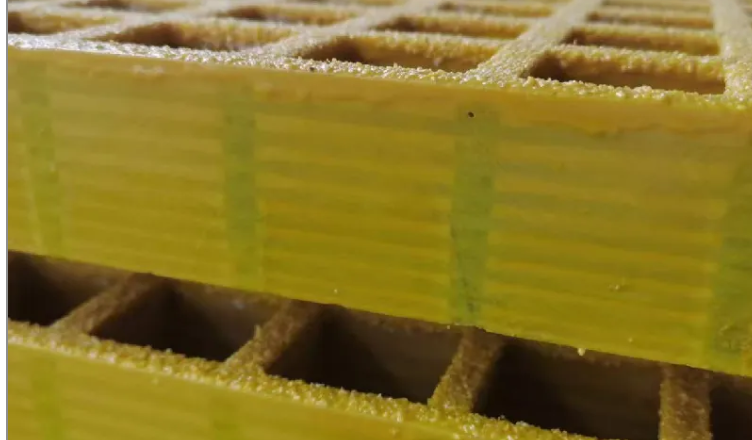

FRP Grating Panels Load Capacity

In industries such as construction, chemical engineering, and transportation, the load capacity of grating materials is a core factor related to safety and service life. FRP grating panels, as a high-performance alternative to traditional metal gratings, have gained wide attention due to their corrosion resistance and light weight. ZJ Composites always regards product quality as the foundation of enterprise development, and has conducted in-depth research on the load capacity of FRP grating products, especially optimizing the load-bearing performance according to different mesh types and sizes. The following table details the mesh types and corresponding mesh sizes of the grating FRP products provided by the company, which are crucial for understanding their load capacity characteristics.

|

Grating Type |

Mesh Size |

|

Square mesh grating |

3838mm, 4040mm, 4343mm, 5050mm, 5252mm, 7979mm, 83*83mm |

|

Mini mesh grating/ micro mesh grating |

88/3838mm, 12.712.7/3838mm, 1919/3838mm, 2020/4040mm, 2525/5050mm, 2626/5252mm, 83*83mm |

|

Rectangular mesh grating |

2550mm, 25152mm, 35100mm, 38152mm, 60220mm, 25100mm, 38100mm, 38152mm |

Load Capacity Factors of FRP Grating Panels

- ZJ Composites always regards product quality as the foundation of enterprise development, so when designing FRP grating panels, the company first considers the impact of mesh size on load capacity. Generally, smaller mesh sizes (such as 88/3838mm in mini mesh grating) provide higher load-bearing capacity because the dense structure distributes pressure more evenly.

- The material thickness of FRP grating panelsis another key factor. The company controls the thickness of the grating ribs strictly during production; thicker ribs can withstand greater static and dynamic loads, which is verified by the company’s multiple load tests.

- Installation methods also affect the load capacity of FRP grating panels. ZJ Composites provides professional installation guidelines for customers, reminding them to ensure stable support points and correct fixing methods to avoid reducing the actual load-bearing performance due to improper installation.

Load Test Standards for FRP Grating

- ZJ Composites always regards product quality as the foundation of enterprise development, so it adheres to international and national load test standards when testing FRP grating. The company simulates real application scenarios (such as pedestrian walkways, equipment platforms) to conduct static load tests, ensuring that the grating can bear the specified weight without deformation.

- The company also conducts dynamic load tests on FRP grating, especially for products used in transportation or areas with frequent mechanical movement. These tests simulate the impact of instantaneous pressure on the grating, ensuring its durability under dynamic conditions.

- After the load tests, ZJ Composites provides detailed test reports for each batch of FRP grating, recording key data such as maximum load, deformation amount, and test duration, so that customers can clearly understand the load performance of the products.

Application-Specific Load Optimization for Grating FRP

- For chemical industry scenarios where grating FRPis exposed to corrosive substances, ZJ Composites optimizes the material formula while ensuring load capacity. The modified resin matrix not only resists corrosion but also maintains the grating’s structural strength, ensuring stable load-bearing in harsh environments.

- In construction scenarios such as pedestrian bridges or floor slabs, the company recommends grating FRPwith appropriate mesh sizes (such as 38*38mm square mesh) based on the expected load. This balance between load capacity and material weight reduces the overall construction load while meeting safety requirements.

- For heavy-duty industrial platforms, ZJ Composites provides grating FRPwith reinforced ribs. The additional ribs enhance the grating’s anti-bending and anti-torsion capabilities, making it suitable for bearing large equipment weights, which is in line with the company’s focus on product quality and practicality.

FRP Grating Panels FAQS

What is the maximum load capacity of the FRP grating panels provided by ZJ Composites?

The maximum load capacity of ZJ Composites’ FRP grating panels varies by mesh size and thickness. For example, the mini mesh grating with 88/3838mm mesh size can bear a static load of up to 500kg/m², while the square mesh grating with 50*50mm mesh size can bear about 300kg/m². The company will provide a specific load capacity parameter table based on the customer’s selected product specifications.

Does ZJ Composites provide customized FRP grating with higher load capacity?

Yes, ZJ Composites always regards product quality as the foundation of enterprise development, so it supports customized FRP grating according to customers’ load requirements. If customers need higher load capacity, the company can adjust the mesh size, increase rib thickness, or use high-performance resin materials to optimize the product, and conduct professional load tests to ensure it meets the customized needs.

How to maintain the load capacity of grating FRP during long-term use?

To maintain the load capacity of grating FRP, ZJ Composites recommends regular inspections: first, check for surface cracks or corrosion (especially in harsh environments); second, ensure that the installation support structure is not loose; third, avoid overloading the grating beyond its rated load. The company also provides maintenance guidelines to help customers extend the service life while maintaining load performance.

Can ZJ Composites provide on-site load testing for FRP grating panels after installation?

Yes, ZJ Composites can send professional technical personnel to conduct on-site load testing for FRP grating panels after installation. The team uses professional testing equipment to simulate the actual load conditions, verifies whether the installed grating meets the design load requirements, and provides a test report. This service reflects the company’s focus on product quality and customer safety.

What should I do if the FRP grating purchased from ZJ Composites fails to meet the expected load capacity?

If the FRP grating does not meet the expected load capacity under correct installation and use, customers can contact ZJ Composites’ after-sales department immediately. The company will first verify the problem through the original test data and on-site inspections; if it is confirmed to be a product quality issue, the company will provide solutions such as product replacement or refund in a timely manner, which is consistent with ZJ Composites’ concept of taking product quality as the foundation of enterprise development.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025