loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor grating price

Understanding Floor Grating Prices A Comprehensive Guide

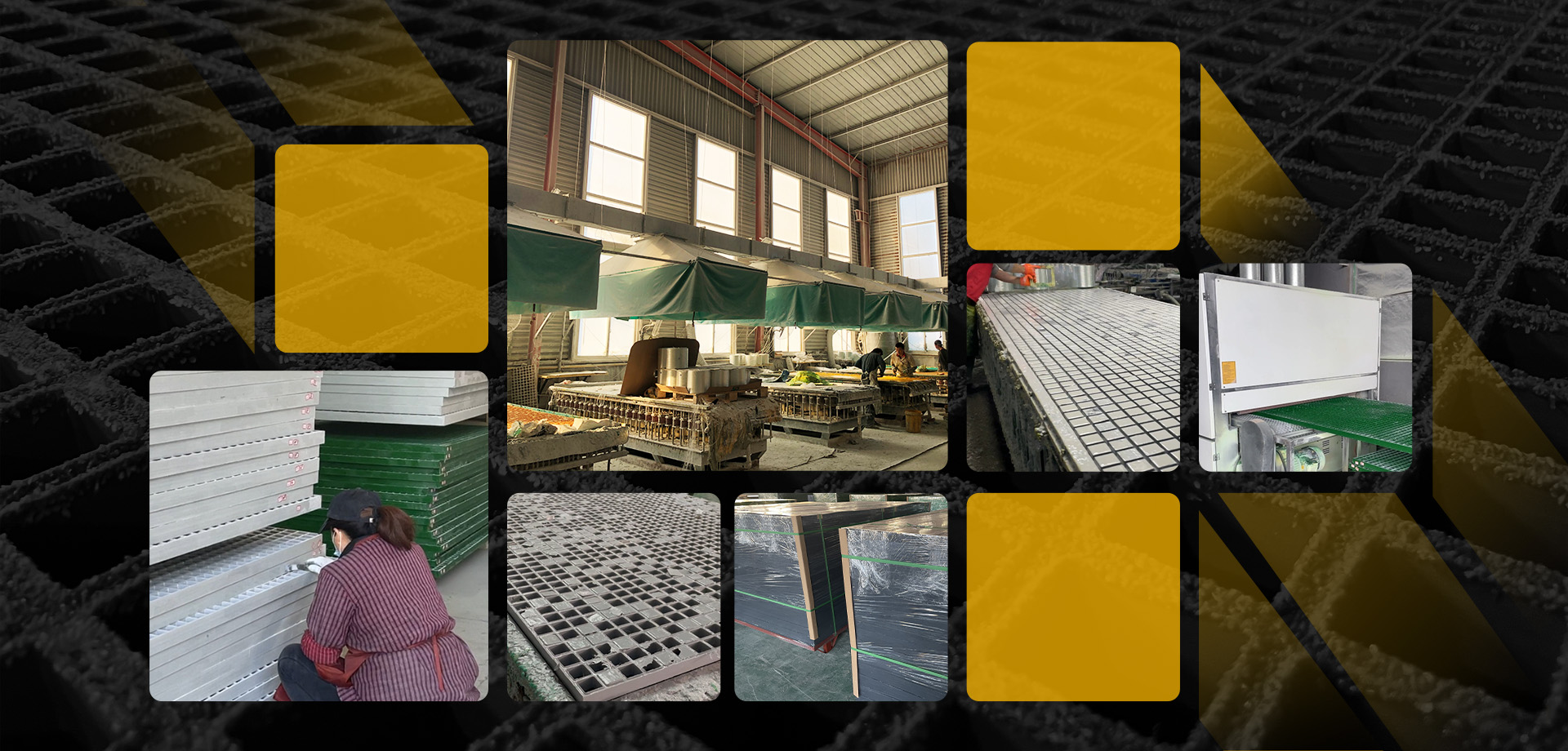

When it comes to industrial and commercial flooring solutions, floor grating is an essential component that offers both safety and practicality. Commonly used in warehouses, factories, and various outdoor settings, floor grating provides a robust and slip-resistant surface. However, one of the critical considerations for businesses and professionals looking to invest in floor grating is its price. In this article, we will explore the factors that influence floor grating prices, various types available, and tips on how to choose the right product for your needs.

What is Floor Grating?

Floor grating is a structure made of metal or composite materials designed to allow light, air, and moisture to pass through while providing support for foot traffic and heavy loads. It is commonly used in walkways, platforms, and drainage applications. The most common materials for floor grating include steel, fiberglass, aluminum, and plastic, each offering unique benefits and drawbacks.

Factors Influencing Floor Grating Prices

1. Material The type of material significantly affects the price of floor grating. Steel grating tends to be the most affordable option but is susceptible to rust and corrosion unless treated. On the other hand, fiberglass grating is more expensive but offers superior durability and resistance to chemicals and moisture. Additionally, aluminum provides an excellent balance of strength and weight, though it often comes at a higher price point.

2. Size and Customization Standard sizes of floor grating may be less expensive than custom-made options. If a project requires specific dimensions or shapes, prices can increase significantly due to the additional labor and materials involved in creating custom grating solutions. It is essential to consider your project's specifications when estimating costs.

3. Load Capacity Floor grating is designed to support varying loads, and those with higher load capacities naturally come with a higher price tag. When selecting grating, it is crucial to assess the weight it will need to support, as choosing an inadequate load-bearing option can lead to safety hazards.

4. Manufacturing Techniques Different manufacturing processes can impact the overall cost of floor grating. For example, welded grating, which involves welding crossbars to the bearing bars, tends to be stronger and more durable than riveted options, but it may also be more expensive.

5. Finish and Coatings The surface finish and protective coatings applied to grating can add to the costs. Anti-slip surfaces, for instance, enhance safety but can increase the price. Similarly, coatings for rust and corrosion resistance can be an additional expense but are often worth the investment in harsh environments.

Types of Floor Grating

floor grating price

- Steel Grating Widely used for its strength and affordability, steel grating is suitable for environments where high weight loads are expected. It is commonly found in industrial settings but requires proper maintenance to prevent rust.

- Fiberglass Grating This lightweight option is ideal for corrosive environments, such as chemical plants and coastal areas. Fiberglass grating is non-conductive and does not rust, making it a safe choice for various applications.

- Aluminum Grating Known for its lightweight nature and resistance to corrosion, aluminum grating is often used in outdoor settings and places where aesthetics are important. It is more costly than steel but offers a longer lifespan with lower maintenance needs.

- Plastic Grating This economical option is best suited for non-load-bearing applications, often used in residential or light commercial settings. Plastic grating is resistant to many chemicals and is easily customizable.

Tips for Choosing the Right Floor Grating

1. Assess Your Needs Determine the specific requirements for your project, including load capacity, environmental conditions, and required durability. This will guide your material choice.

2. Compare Prices Shop around and compare prices from different suppliers. Consider not only the initial costs but also maintenance and long-term durability when budgeting.

3. Quality Matters Cheaper products might save you money upfront, but they can lead to increased maintenance and replacement costs in the long run. Invest in quality grating to ensure safety and longevity.

4. Consult Professionals If you are unsure about the type or specifications of the grating that would be best for your application, consult with professionals or suppliers who can provide expert guidance.

In conclusion, floor grating prices can vary greatly depending on a multitude of factors, including material, size, load capacity, manufacturing techniques, and finishes. By understanding these variables and carefully assessing your needs, you can make an informed decision that ensures safety and value for your investment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025