loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Grating Suppliers – Certified Quality, Custom Sizes

Frp Grating Suppliers is a key solution in the Architecture and Building Materials industry, specifically within Composite material products and fiberglass grating. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frp Grating Suppliers Overview

- Benefits & Use Cases of Frp Grating Suppliers in fiberglass grating

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Architecture and Building Materials

- Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

Frp Grating Suppliers Overview

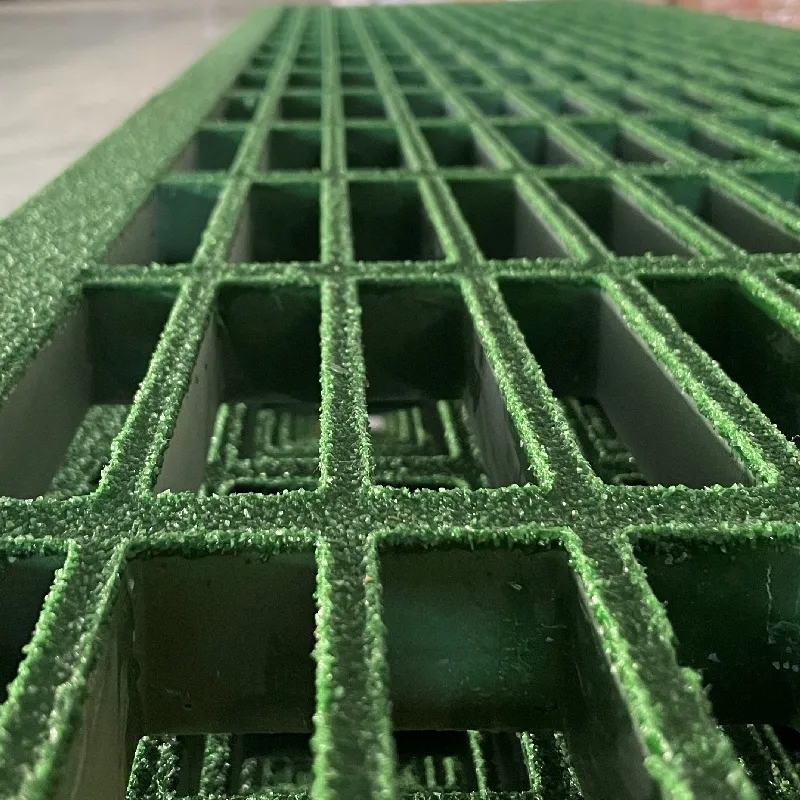

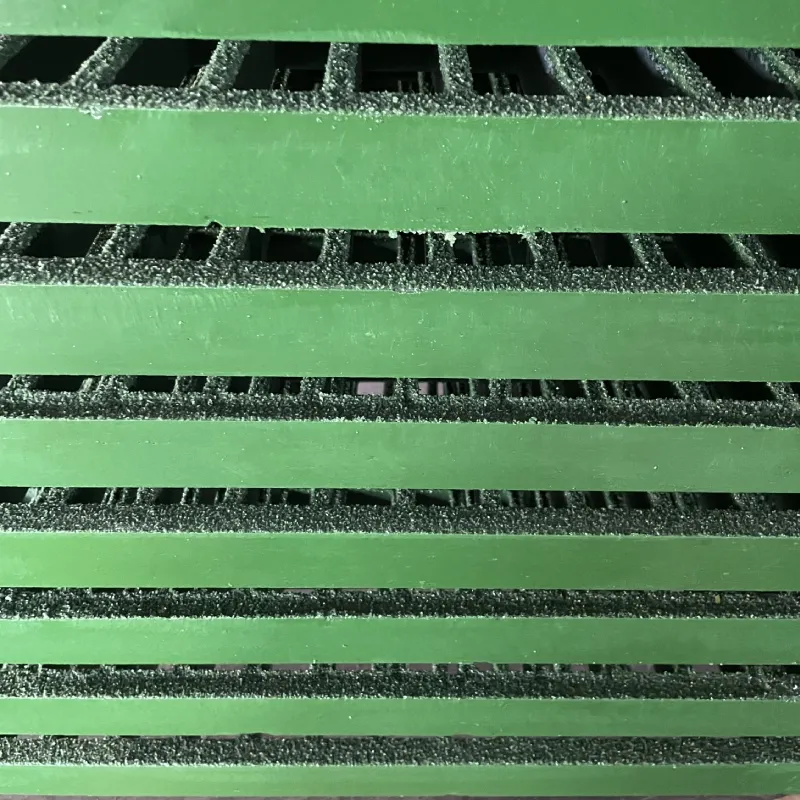

For B2B decision makers evaluating safe, corrosion-resistant access systems, FRP (fiber-reinforced polymer) grating delivers a compelling alternative to steel. Molded fiberglass rectangular mesh grating combines glass fiber reinforcements with thermoset resins to create panels that are light in weight, high in strength, and intrinsically non-conductive. In the Architecture and Building Materials supply chain—especially within composite material products—FRP grating is specified for platforms, walkways, trenches, and mezzanines where corrosion, moisture, or chemicals shorten the life of metal solutions. Many buyers search for “FRP grating” or even “.frp grating” in catalogs; both terms point to the same durable, safety-focused product class.

- Technical profile: typical thicknesses range from 25–60 mm; mesh can be square or rectangular to optimize open area and drainage; standard anti-slip surfaces include meniscus or embedded grit; resin systems (isophthalic, vinyl ester, phenolic options) can be specified for enhanced chemical resistance and low flame spread.

- Performance highlights: high strength-to-weight ratio eases handling and speeds installation; UV stabilizers and pigments support outdoor durability; FRP’s dielectric properties support electrical safety in substations and industrial plants.

- Reliable manufacturing: Zhaojia Composites Co., Ltd engineers molded fiberglass rectangular mesh grating with consistent fiber wet-out and resin distribution, delivering predictable load performance and long service life for industrial and architectural environments. Explore the product page for specifications and options.

Benefits & Use Cases of Frp Grating Suppliers in fiberglass grating

From chemical processing lines to coastal infrastructure, partnering with experienced Frp Grating Suppliers ensures the right resin, mesh, and surface finish for each environment. In wastewater plants, rectangular mesh FRP enhances drainage and slip resistance on clarifier bridges. In marine and offshore, its corrosion resistance outperforms galvanized steel on docks and platforms. Food and beverage facilities value FRP’s non-conductive, easy-to-clean surface for CIP areas, while power generation sites deploy FRP around cooling towers and transformers to reduce maintenance downtime.

- Application depth: walkways, trench covers, cable trays, rooftop access, mezzanines, and equipment platforms—especially where exposure to saltwater, acids, alkalis, or moisture is routine.

- Competitive advantages: excellent corrosion resistance, intrinsic dielectric properties, high slip resistance (gritted top), low weight for faster installs, and modularity for field cutting without hot works.

- Supplier expertise: Zhaojia Composites Co., Ltd supports project-specific engineering, cut-to-size services, color coding for zones, and resin selection guidance to meet performance targets and compliance requirements.

Cost, Maintenance & User Experience

Total cost of ownership often determines the business case. While FRP grating can be comparable to, or slightly above, initial steel costs on certain sizes, lifecycle economics typically favor FRP in corrosive settings. There is no need for periodic repainting, galvanizing touch-ups, or rust remediation, and panels are easy to lift for inspection—reducing labor and lifting equipment requirements. Many asset owners report payback in maintenance-heavy zones within two to three years, driven by avoided coatings and fewer shutdowns.

- Durability and ROI: long service life, colorfast pigments, and robust slip resistance sustain safety performance; reduced corrosion risk protects adjacent assets and extends inspection intervals.

- Voice of customers: facility managers in chemical processing and water treatment cite year-over-year OPEX savings, simpler housekeeping, and improved safety culture due to non-conductive, anti-slip tops. EPC contractors highlight installation productivity from lighter panels and fewer hot works permits.

Sustainability & Market Trends in Architecture and Building Materials

Sustainability priorities are reshaping material selection across the built environment. FRP grating contributes through long lifecycle performance, reduced repainting and blasting, and lower transport emissions per square meter thanks to its favorable strength-to-weight ratio. As regulations tighten around worker safety and environmental impact, specifiers are shifting toward materials that minimize maintenance-related VOCs and waste while maintaining slip resistance and fire performance. Demand is rising in water infrastructure, ports, renewables, and data center cooling systems—segments seeking corrosion resistance and predictable long-term costs.

- Market direction: growth in composite access systems is supported by stricter safety codes, lifecycle assessments, and a move toward modular, prefabricated platforms that FRP enables.

- Future-ready supplier: Zhaojia Composites Co., Ltd emphasizes material efficiency, supports low-VOC resin options where applicable, and consults on designs that reduce mass without compromising load capacity—helping clients meet ESG targets alongside performance KPIs.

Conclusion on Frp Grating Suppliers from Zhaojia Composites Co., Ltd

Selecting the right partner among Frp Grating Suppliers can transform platform safety, corrosion resistance, and lifecycle costs across industrial and architectural projects. FRP grating’s non-conductive, slip-resistant, and low-maintenance profile makes it a strategic choice for B2B owners, EPCs, and facility operators. Zhaojia Composites Co., Ltd stands out for application-driven engineering, reliable quality, and responsive support from specification to installation. Contact us: email: admin@zjcomposites.com — Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025