loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced Applications of Fiber Reinforced Polymer Gratings in Structural Engineering

Understanding FRP Grating A Comprehensive Overview

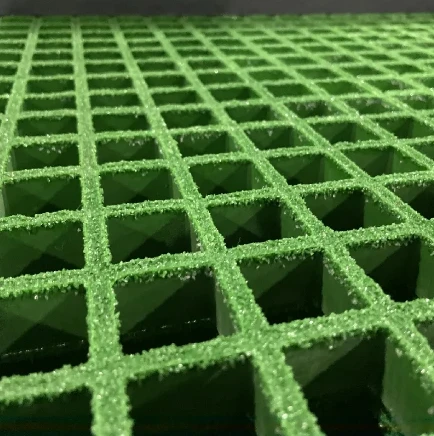

Fiber Reinforced Plastic (FRP) grating has become a pivotal material choice in diverse industrial applications due to its unique properties and advantages over traditional materials. Composed of a high strength-to-weight ratio, corrosion resistance, and impressive durability, FRP grating finds its place in environments that demand reliability and performance.

What is FRP Grating?

FRP grating is a type of composite grating made from a combination of fiberglass reinforcements embedded in a polymer matrix. The primary elements of FRP are the fiberglass, which provides structural strength, and the resin, typically either polyester, vinylester, or epoxy, which offers chemical resistance and thermal stability. This combination results in a product that can be tailored to specific needs and conditions, making it versatile for various uses.

Key Benefits of FRP Grating

1. Corrosion Resistance One of the most significant advantages of FRP grating is its resistance to corrosive environments. Unlike steel or aluminum, which can rust or degrade when exposed to chemicals, salts, and moisture, FRP grating remains intact and functional, extending its lifecycle and minimizing maintenance costs.

2. Lightweight and High Strength FRP is notably lighter than traditional materials, making it easier to handle and install. This characteristic not only reduces labor costs but also allows for the construction of structures with a lower load-bearing requirement. Despite its lightness, FRP grating offers a high strength-to-weight ratio, making it ideal for demanding applications.

3. Electrical Insulation As a non-conductive material, FRP grating provides electrical insulation, making it a suitable choice for environments where electrical safety is paramount. This property is particularly advantageous in areas such as power plants, substations, and chemical processing facilities.

4. Customizability FRP grating can be manufactured in various sizes, thicknesses, and colors. This adaptability allows designers and engineers to choose specific features that best meet project requirements, whether it’s increasing visibility with colored grating or maximizing load-bearing capabilities with thicker profiles.

frp grating

5. Maintenance-Free The durability and resistance to elements lead to minimal maintenance needs compared to traditional materials. Since FRP does not require painting, sealing, or rust prevention treatments, it significantly reduces lifetime costs associated with upkeep.

Applications of FRP Grating

FRP grating is used across many sectors, including

- Industrial Flooring It provides a stable walking surface for workers in manufacturing plants, warehouses, and other industrial settings, especially in sectors where chemical spills could be a concern. - Walkways and Bridges Its lightweight properties make FRP grating an excellent choice for pedestrian walkways and lightweight bridge structures, particularly in remote or hard-to-reach locations where heavy machinery cannot operate.

- Wastewater Treatment Facilities Given its corrosion resistance, FRP grating is ideal for use in environments with high levels of moisture and chemical exposure, such as wastewater treatment plants.

- Marine Applications Boat docks, piers, and other marine structures benefit from FRP's resistance to seawater and UV radiation, ensuring they withstand harsh environmental conditions.

Conclusion

In conclusion, FRP grating stands out as a modern solution for a variety of industrial, commercial, and marine applications. Its unique combination of properties—corrosion resistance, lightweight, high strength, electrical insulation, customizability, and maintenance-free life—ensures that it meets the demanding needs of today’s industries. As technology advances and the need for reliable, efficient materials continues to grow, FRP grating is likely to play an increasingly significant role in the development of safer and more sustainable infrastructure. Whether you're involved in design, engineering, or facility management, understanding the benefits and applications of FRP grating is essential for making informed decisions in material selection.

-

The Expansive Industrial Reign of FRP Pressure VesselsNewsAug.22,2025

-

Manufacturing Premium FRP Square Pipes for Global Wholesale ExcellenceNewsAug.22,2025

-

Strategic Applications for FRP Grating SolutionsNewsAug.22,2025

-

Material Science Forging GRP Water Tank LongevityNewsAug.22,2025

-

The Engineered Excellence: Material Science Behind FRP Railing SystemsNewsAug.22,2025

-

How Digital Pultrusion Revolutionizes FRP Profile WholesalingNewsAug.22,2025

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025