loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 11, 2025 13:36

Back to list

cartridge filter vessel

Cartridge filter vessels are invaluable components in various industrial processes, serving as critical tools for achieving pure and reliable filtration. Drawing from decades of experience in the field of filtration systems, it is clear that the expertise surrounding cartridge filter vessels is critical for optimal operation.

The authority around cartridge filter vessels is evident in their application across industries requiring stringent standards for fluid purity. One must adhere to strict regulatory requirements when implementing these systems. Industries like pharmaceuticals and food and beverage manufacturing use these vessels to remove contaminants that could compromise product safety. Such applications reinforce the authoritative importance of cartridge filter vessels in maintaining compliance with health and safety regulations. Trustworthiness is paramount in the context of cartridge filter vessels. Reliability in performance ensures that operations run smoothly without the risk of contamination or system failure. Trust in these systems is built over time, with manufacturers often offering extended warranties and testing protocols to validate a vessel's performance under different conditions. This trust is enhanced by innovations in design and engineering that cater to evolving industry needs, ensuring that cartridge filter vessels continue to meet and exceed performance expectations. Overall, the integration of cartridge filter vessels into an operational system requires a blend of real-world experience, technical expertise, authoritative understanding of industry standards, and a commitment to trustworthiness. As industry needs evolve, advancements in technology promise further enhancements in the efficiency and capability of these reliable filtration solutions. This ongoing innovation not only demonstrates the significance of cartridge filter vessels today but also the potential for even greater impact in the future, cementing their role as essential tools in industrial processes globally.

The authority around cartridge filter vessels is evident in their application across industries requiring stringent standards for fluid purity. One must adhere to strict regulatory requirements when implementing these systems. Industries like pharmaceuticals and food and beverage manufacturing use these vessels to remove contaminants that could compromise product safety. Such applications reinforce the authoritative importance of cartridge filter vessels in maintaining compliance with health and safety regulations. Trustworthiness is paramount in the context of cartridge filter vessels. Reliability in performance ensures that operations run smoothly without the risk of contamination or system failure. Trust in these systems is built over time, with manufacturers often offering extended warranties and testing protocols to validate a vessel's performance under different conditions. This trust is enhanced by innovations in design and engineering that cater to evolving industry needs, ensuring that cartridge filter vessels continue to meet and exceed performance expectations. Overall, the integration of cartridge filter vessels into an operational system requires a blend of real-world experience, technical expertise, authoritative understanding of industry standards, and a commitment to trustworthiness. As industry needs evolve, advancements in technology promise further enhancements in the efficiency and capability of these reliable filtration solutions. This ongoing innovation not only demonstrates the significance of cartridge filter vessels today but also the potential for even greater impact in the future, cementing their role as essential tools in industrial processes globally.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

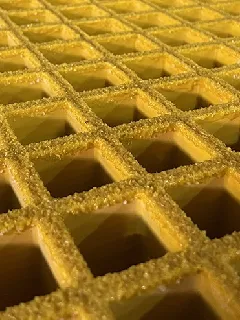

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025