loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp structural sections

Understanding FRP Structural Sections Revolutionizing Construction Materials

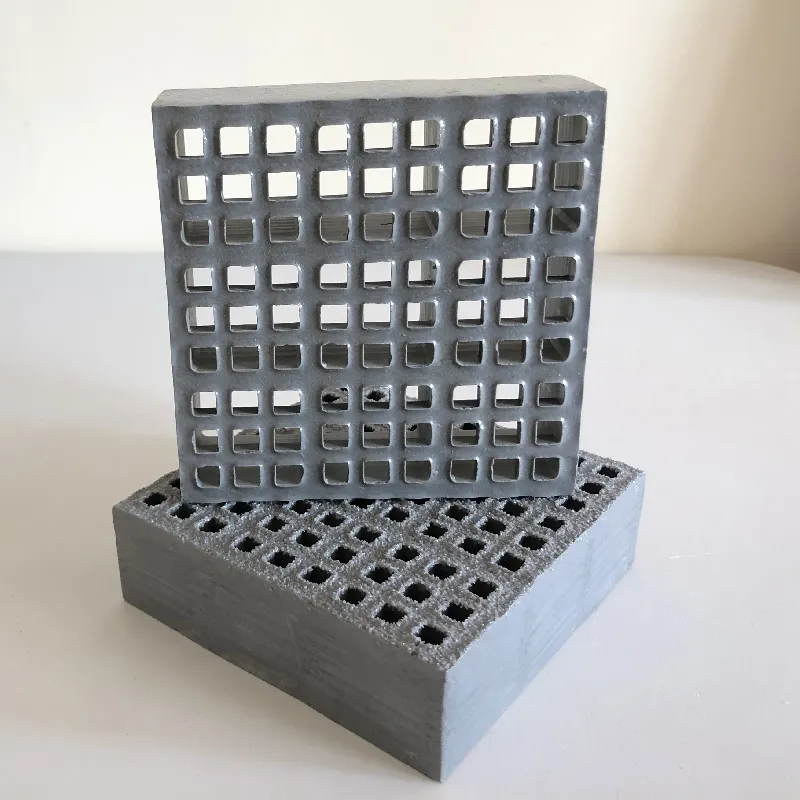

Fiber-Reinforced Polymer (FRP) structural sections are gaining significant traction in the construction and engineering industries due to their unique properties and benefits. As a composite material, FRP is made from a polymer matrix reinforced with fibers, such as carbon, glass, or aramid. This innovative material is transforming traditional building methods and providing solutions that were previously unattainable with conventional construction materials like steel and concrete.

The Composition and Types of FRP

FRP is composed of two primary constituents the matrix (polymer) and the reinforcement (fiber). The matrix provides the shape, while the fibers contribute to the load-bearing capacity and overall strength. There are several types of FRP, categorized primarily by the type of fiber used

1. Glass Fiber-Reinforced Polymer (GFRP) This is the most commonly used type of FRP due to its cost-effectiveness and good mechanical properties. GFRP is lightweight, resistant to corrosion, and offers decent strength-to-weight ratios.

2. Carbon Fiber-Reinforced Polymer (CFRP) Known for its superior strength and stiffness, CFRP is ideal for applications that demand high performance. It is often used in aerospace, automotive, and some high-end construction projects despite its higher cost.

3. Aramid Fiber-Reinforced Polymer (AFRP) This type is noted for its impact resistance and toughness, making it suitable for applications where high durability is essential.

These diverse types of FRP allow engineers and architects to select the most appropriate material based on specific project requirements such as weight, cost, and strength.

Advantages of FRP Structural Sections

The adoption of FRP structural sections presents numerous advantages over traditional materials

1. Corrosion Resistance One of the most significant benefits of FRP is its resistance to environmental degradation. Unlike steel, FRP does not rust or corrode, making it an ideal choice for structures exposed to harsh environments, such as bridges, marine applications, and chemical processing facilities.

frp structural sections

2. Lightweight FRP is considerably lighter than steel and concrete, which simplifies handling and reduces transportation costs. The lower weight also results in less load on foundations, allowing for innovative and economical design solutions.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP exhibits exceptional strength, enabling the construction of slender and aesthetically pleasing structures without compromising on load-bearing capacity.

4. Flexibility in Design FRP can be molded into complex shapes, offering architects and engineers greater design freedom. This versatility can lead to unique structures that are not feasible with traditional materials.

5. Thermal and Electrical Insulation FRP does not conduct electricity and has good thermal insulation properties, which can enhance safety and energy efficiency in building designs.

6. Sustainability The production and use of FRP can be more environmentally friendly compared to traditional materials. Additionally, many types of FRP can be recycled, further contributing to sustainable construction practices.

Challenges in FRP Utilization

While FRP has many advantages, there are challenges that must be addressed for wider acceptance in the construction industry. One of the main concerns is the current lack of established standards and codes for FRP materials, which can lead to hesitance among engineers and builders. Moreover, the initial costs of FRP can be higher than traditional materials, although lifecycle costs may demonstrate long-term savings due to durability and maintenance considerations.

Applications of FRP Structural Sections

FRP structural sections are finding applications across various sectors. In civil engineering, they are used for bridge components, reinforcing beams and columns, and even entire structures. In the aerospace and automotive industries, CFRP is extensively used for parts that require high strength with minimal weight, such as wings and body panels. Additionally, FRP is increasingly being utilized in the construction of recreational facilities, such as stadiums and swimming pools, where the benefits of lightweight and durability are particularly advantageous.

Conclusion

The future of construction materials is undoubtedly moving towards the integration of advanced composites like FRP. As research continues and standards develop, FRP structural sections are expected to become more commonplace in structural design. Their unique properties offer solutions to many challenges faced in traditional construction, promising a more innovative and sustainable approach to building the infrastructure of tomorrow. Engineers and architects who embrace FRP technology will be at the forefront of this monumental shift, redefining the possibilities of construction.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025