loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Applications and Benefits of FRP Pressure Vessels in Industry

Understanding FRP Pressure Vessels A Comprehensive Overview

Fiber Reinforced Polymer (FRP) pressure vessels have gained significant traction in various industries due to their unique properties and advantages over traditional materials like metal. These vessels are engineered to withstand high pressure and corrosive conditions, making them ideal for a variety of applications, including chemical storage, oil and gas, and even water treatment.

What are FRP Pressure Vessels?

FRP pressure vessels are constructed using a composite material that consists of a polymer matrix reinforced with fibers, typically glass or carbon. This composite construction gives FRP vessels high strength-to-weight ratios, excellent corrosion resistance, and thermal stability. The layering of fibers within the polymer matrix is designed in such a way that it optimally distributes stress throughout the vessel, enhancing its overall strength and durability.

Advantages of FRP Pressure Vessels

1. Corrosion Resistance One of the most compelling advantages of FRP vessels is their resistance to chemical corrosion. Unlike traditional steel vessels, which can rust and degrade over time when exposed to harsh chemicals, FRP vessels can endure such environments without significant damage.

2. Lightweight FRP pressure vessels are much lighter than their metal counterparts, which can lead to easier handling, installation, and transportation. This lightweight nature can also result in reduced structural support requirements, saving costs in construction and installation.

3. Thermal Insulation The insulation properties of FRP can help in maintaining the temperature of the contents inside the vessel, which can be crucial for processes that require specific thermal conditions.

4. Customizable Design FRP technology allows for a high degree of customization in terms of size, shape, and design. This versatility makes FRP vessels suitable for a broad range of industrial applications.

5. Lower Lifecycle Costs While the initial investment in FRP technology can be higher than traditional materials, the long-term savings in maintenance, replacement, and operational costs can make FRP vessels a more economical choice over their lifespan.

frp pressure vessels

Applications of FRP Pressure Vessels

FRP pressure vessels are widely employed in various sectors

- Chemical Processing These vessels are ideal for storing and transporting corrosive chemicals, where traditional materials would fail.

- Oil and Gas Due to their high strength and resistance to harsh environments, FRP vessels are used in offshore oil and gas installations, particularly for storing fluids before processing.

- Water Treatment Many water treatment plants utilize FRP vessels for the storage of treated water and chemicals used in the treatment process, benefiting from their corrosion resistance.

- Aerospace The lightweight nature of FRP materials makes them an attractive option for pressure vessels in aerospace applications, where weight savings are critical.

Challenges and Considerations

Despite the many advantages of FRP pressure vessels, there are challenges to consider. The manufacturing process can be complex and may require specialized knowledge and equipment. Additionally, while FRP materials are resistant to many chemicals, they are not invulnerable; careful consideration must be given to the specific materials involved in the application to avoid degradation.

Conclusion

FRP pressure vessels represent a significant advancement in material science, offering numerous advantages such as corrosion resistance, lightweight properties, and lower lifecycle costs. Their applications span various industries, making them a vital component in modern engineering solutions. As technology advances and manufacturing processes improve, the adoption of FRP pressure vessels is expected to grow, further enhancing efficiency and sustainability in multiple sectors. Understanding the properties and applications of FRP pressure vessels will be crucial for engineers and decision-makers as they seek to implement the best solutions for their needs.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

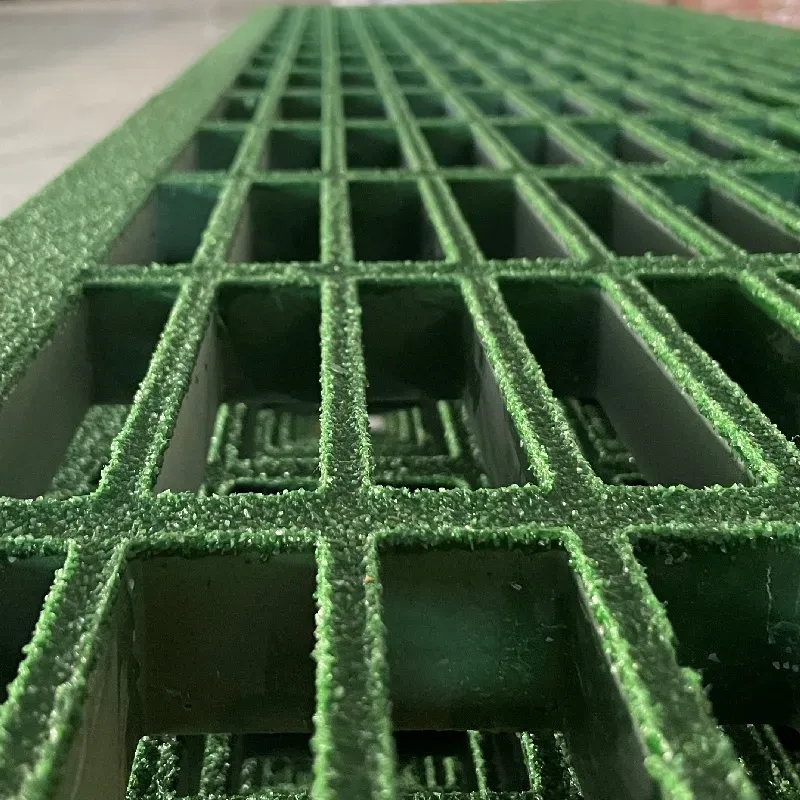

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025