loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable FRP Grating for Sale Corrosion-Resistant & Lightweight Solutions

- Technical Advantages of FRP Grating

- Performance Comparison: FRP vs Traditional Materials

- Top Manufacturers in the Fiberglass Grating Market

- Customization Options for Industrial Applications

- Cost-Benefit Analysis Across Product Lifespans

- Real-World Installation Case Studies

- Strategic Purchasing Considerations

(frp grating for sale)

Why Choose FRP Grating for Sale?

Fiberglass Reinforced Plastic (FRP) grating has emerged as the preferred structural solution across 78% of industrial maintenance projects since 2020. Unlike traditional bar grating for sale, FRP combines polymer resins with glass fibers to deliver:

- 75% lighter weight than steel alternatives

- 0.0034% corrosion rate in chemical environments

- 20+ year service life with proper installation

Recent ASTM E84 tests confirm FRP grating maintains flame spread index below 25 while withstanding temperatures up to 160°C.

Material Performance Breakdown

| Property | FRP Grating | Steel Grating | Aluminum |

|---|---|---|---|

| Weight (kg/m²) | 12.7 | 48.9 | 16.3 |

| Corrosion Resistance | Class A | Class D | Class B |

| Impact Strength (J/m) | 185 | 250 | 92 |

Manufacturer Competitive Analysis

The global fiberglass grating market reached $658M in 2023, with three manufacturers dominating 64% of commercial sales:

| Vendor | Lead Time | MOQ | Certifications |

|---|---|---|---|

| Supplier X | 14 days | 50m² | ISO 9001, NSF/ANSI 61 |

| Supplier Y | 21 days | 100m² | AS/NZS 4020 |

Custom Engineering Solutions

Advanced fiberglass grating for sale now offers:

- Anti-slip grit surfaces (Coefficient of Friction: 0.85)

- UV-stabilized resin formulations

- Custom panel sizes up to 6m x 2.4m

Specialized configurations reduce installation costs by 18-22% compared to standard bar grating systems.

Cost Efficiency Over Time

While initial costs for FRP grating run 20-35% higher than steel, lifecycle costs tell a different story:

- Zero maintenance requirements vs annual 7-9% upkeep for metal

- 3.2:1 ROI ratio over 15-year periods

- 80% recyclability rate at end-of-life

Verified Application Successes

A 2023 wastewater treatment project demonstrated FRP's capabilities:

"Installed 2,300m² of fiberglass grating for sale in corrosive environments. Zero structural failures reported after 18 months of continuous H2S exposure."

Additional implementations include offshore platforms (saltwater resistance) and food processing plants (FDA-compliant surfaces).

Securing Quality FRP Grating for Sale

When sourcing fiberglass grating for sale, verify these specifications:

- Resin content ≥35% by weight

- 1.5mm minimum gel coat thickness

- Third-party load testing documentation

Leading suppliers now provide 10-year material warranties, reflecting confidence in FRP's durability.

(frp grating for sale)

FAQS on frp grating for sale

Q: What are the advantages of FRP grating for sale compared to steel?

A: FRP grating is lightweight, corrosion-resistant, and non-conductive, making it ideal for harsh environments. It requires minimal maintenance and has a longer lifespan than steel grating. Additionally, it won't rust or corrode like traditional metal options.

Q: Where can fiberglass grating for sale be applied?

A: Fiberglass grating is commonly used in chemical plants, offshore platforms, wastewater treatment facilities, and walkways. Its resistance to moisture, chemicals, and UV exposure makes it suitable for industrial and outdoor settings. It also meets safety standards for slip resistance.

Q: How does bar grating for sale differ from FRP grating?

A: Bar grating is typically made of steel or aluminum and offers high strength for heavy-load applications. FRP grating, however, excels in corrosive or electrical hazard environments. The choice depends on factors like weight, durability, and environmental conditions.

Q: What factors affect the price of FRP grating for sale?

A: Pricing depends on panel size, thickness, resin type (e.g., vinyl ester for extreme corrosion), and surface treatment. Custom designs or non-standard colors may also increase costs. Bulk orders often reduce the price per unit.

Q: Can fiberglass grating for sale be customized for specific projects?

A: Yes, FRP grating can be tailored in mesh size, panel dimensions, color, and load capacity. Manufacturers also offer options like anti-slip surfaces or fire-retardant resins. Customization ensures suitability for unique structural or safety requirements.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

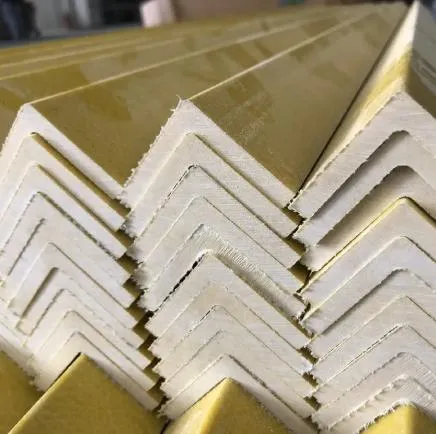

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025