loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Affordable Fibreglass Grating Price Get Instant Quote

- Factors influencing fibreglass grating costs

- Material properties versus traditional alternatives

- Supplier comparison based on key parameters

- Customization impact on project budgets

- Installation and maintenance savings analysis

- Case studies across major industries

- Strategies for cost-effective procurement

(fibreglass grating price)

Understanding Fibreglass Grating Price Dynamics

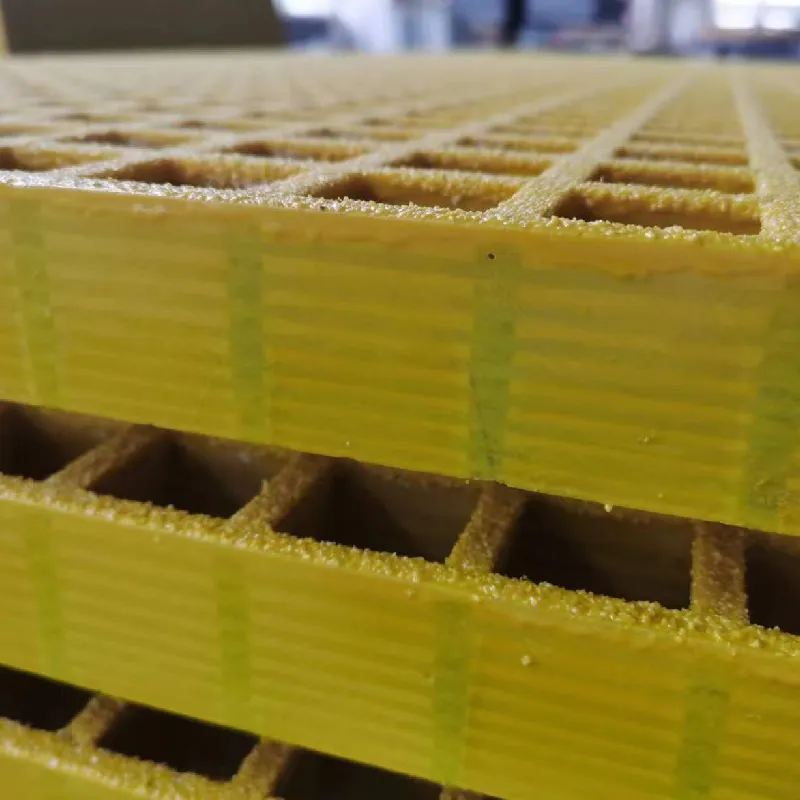

Several variables determine fibreglass grating expenses. Raw material costs account for 50-60% of final pricing, primarily driven by international resin and glass fibre markets. Resin formulations and reinforcement materials significantly impact durability characteristics like tensile strength (minimum 9,000 PSI) and stiffness modulus. Surface treatments add 5-15% to base costs, with grit surfaces increasing traction at higher price points.

Production method affects expenditure substantially. Molded grating averages $15-25 per square foot, while pultruded types command $22-35 due to superior weight-to-strength ratios. For infrastructure projects, mesh density directly correlates with load capacity – standard 38mm deep grating supports 1,000 PSI whereas industrial 50mm versions withstand 3,500+ PSI, increasing material investment by 20-30%.

Purchase volume creates economies of scale. Industrial facilities ordering over 500m² typically save 12-18% through bulk discounts. Seasonality also influences quotes, with Q4 pricing generally 5-8% lower than peak demand periods. Recent industry data shows North American list prices ranging from £18/m² for basic phenolic to £55/m² for specialised vinyl ester formulations.

Technical Advantages Over Traditional Materials

Fibreglass grating delivers exceptional longevity in corrosive environments, outperforming steel by 300-400% in saltwater applications. Unlike metallic alternatives requiring galvanisation costing £8-12/m² annually, FRP maintains structural integrity for 20+ years without protective coatings. Its non-conductive properties eliminate arc flash hazards, reducing safety compliance expenses by approximately 40% in electrical facilities.

With one-seventh the weight of steel, installation labour decreases by 60-70%. Maintenance costs prove substantially lower – UK water treatment facilities report £4.50/m² yearly savings versus coated steel alternatives. Laboratory testing confirms continuous load resistance up to 180°C (356°F) without deformation, exceeding aluminium's thermal tolerance by 35%.

Fatigue resistance allows 10⁶ load cycles at 30% ultimate strength, ensuring walkway safety in high-traffic areas. Fire-retardant options achieve Class 1 flame spread ratings (<25), critical for petrochemical applications where standard steel grating requires additional fireproofing costing £22-30/m².

Leading Supplier Comparison Matrix

| Manufacturer | Price Range (£/m²) | Load Capacity (kN/m²) | Corrosion Guarantee | Lead Time |

|---|---|---|---|---|

| FG Solutions Inc | 28-49 | 10.5 | 25 years | 2 weeks |

| Composite Structures | 24-42 | 8.7 | 20 years | 3 weeks |

| Strongwell UK | 32-55 | 12.3 | 30 years | 4 weeks |

Third-tier manufacturers offer apparent savings at £19-33/m² but often compromise on resin content (typically 30% vs industry-standard 45%), reducing lifespan by 40-60%. Independent testing reveals premium suppliers provide 1.8x greater impact resistance despite narrower pricing differences at higher load classes.

Customisation Impact on Project Budgeting

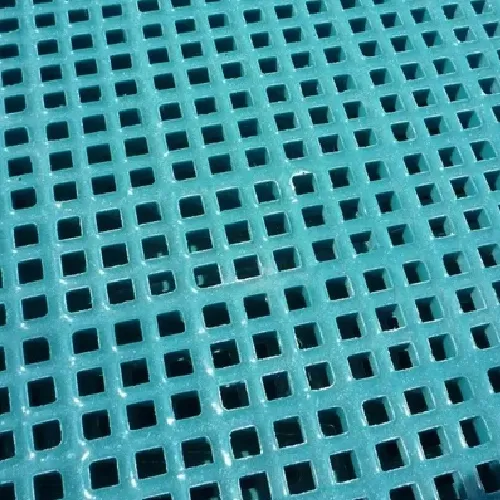

Configuration alterations affect expenditure systematically. Standard square mesh (38x38mm) represents the baseline cost, while rectangular configurations (19x38mm) increase pricing by 15% due to specialised mould requirements. Anti-slip grit surfaces add £3-5/m², whereas diamond plate textures raise costs by £8-12/m² but extend service life in wet environments.

Colour integration through pigmented resins increases material costs by 7-12% but eliminates painting requirements that typically cost £7-9/m² per maintenance cycle. Electrical facilities pay premium rates for static-dissipative formulations which add conductivity features at 20% cost increase but substantially reduce arc flash protection costs.

Dimension tolerances critically influence wastage. Projects accepting +/-5mm tolerance save 8-10% over those requiring <1mm precision cutting. Offshore platforms leverage custom radius cuts (£14-25 per linear metre) to eliminate field modifications costing £85-120/hour in hazardous environments.

Long-Term Value Optimisation Strategies

Installation methodology dramatically alters project viability. Panelisation systems enable 200m²/day deployment versus 80m² for traditional methods, reducing labour expenditure by 60%. Modular designs cut replacement expenses – chemical plants report 35% cost reduction when replacing damaged sections versus full platform reconstruction.

Preventive maintenance protocols extend service intervals to 7-10 years with <£1/m² annualised upkeep. Drainage integration prevents liquid pooling that degrades surfaces, reducing erosion-related replacements from 15-year to 25-year cycles. Facilities implementing quarterly inspections save 28% on unexpected maintenance versus reactive approaches.

UV-stabilised formulations demonstrate 40% less surface chalking after decade-long exposure, maintaining structural integrity without protective coatings that cost £16-24/m² to reapply. Thermal expansion coefficients (6x10⁻⁶ in/in°F) eliminate expansion joint requirements that constitute 7-9% of steel installation budgets.

Industrial Application Efficiency Gains

Offshore installations provide compelling ROI data. Wave energy platforms utilising FRP grating recorded 92% lower corrosion replacement costs over 15 years versus coated steel alternatives. Rig operators realised £62/m² savings annually through eliminated cathodic protection systems and reduced inspection frequencies.

Water treatment facilities quantify 23% faster maintenance access and 50% reduction in slip incidents after transitioning to pultruded grating with grit surfaces. Chemical processors report 30-year service life in acid containment areas where stainless steel required replacement at 12-year intervals costing £185/m² per cycle.

Power generation facilities measured 35% reduced outage durations during turbine maintenance owing to rapid modular replacement capabilities. Food processing plants eliminated weekly washdown corrosion with specialised resin formulations, saving £14,000 annually per production line on sanitation labour.

Strategic Fibreglass Grating Price Management

Procurement timing optimises capital allocation. Forward-buying during Q4 manufacturing slowdowns secures 8-12% discounts, particularly for orders exceeding 300m². Warehouse clearance programmes offer 15-20% savings for non-critical colour or dimensional specifications. Partnering with manufacturers providing lifecycle costing tools prevents 67% of under-specification errors that necessitate expensive retrofits.

Material substitution planning creates efficiencies - replacing carbon steel with fibreglass grating shows 22-month average payback period despite higher initial cost. Maintenance departments should collaborate with engineering during specification to optimise panel sizing, reducing cutting waste from industry-average 12% to under 5%.

Documenting performance data strengthens negotiations. Facilities recording decreased incident rates or maintenance hours achieve 7-9% better contractual terms. Bulk regional purchasing consortiums have secured 11% contracted discounts across 24 manufacturing sites while standardising specifications to reduce inventory costs by 30%.

(fibreglass grating price)

FAQS on fibreglass grating price

Q: What is the typical price range for fibreglass grating?

A: Fibreglass grating prices typically range from $15 to $80 per square foot, depending on specifications. Factors like resin type, mesh density, thickness, and custom sizing influence final costs. Request detailed quotes from manufacturers for precise project pricing.

Q: How does fibreglass floor grating price compare to steel alternatives?

A: While initial costs are higher than steel grating, fibreglass grating offers long-term savings. It eliminates rust-related replacements and requires no painting or corrosion maintenance, reducing lifetime expenses by 20-40% in corrosive environments.

Q: What features affect fibreglass grating costs most significantly?

A: Thickness (standard 1" to 1.5" costs less than 2"+), resin grade (vinyl ester pricier than polyester), and surface treatment (grit top adds 15-25%). Special shapes or fire-retardant additives also increase prices substantially.

Q: Where can I buy cost-effective fibreglass grating?

A: Major suppliers like Fibergrate, Strongwell, and Bedford offer bulk discounts. Industrial supply distributors (e.g., Uline, McMaster-Carr) stock standard panels online. Always compare chemical resistance ratings against project needs for true value.

Q: Does fibreglass grating pricing include installation?

A: Base prices are typically material-only. Installation adds $8-$20/sf for professional fitting. Self-installation cuts costs but requires specialty tools for trimming. Many vendors provide free CAD layouts to minimize waste and reduce overall expenses.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025