loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

tammi . 09, 2025 12:09

Back to list

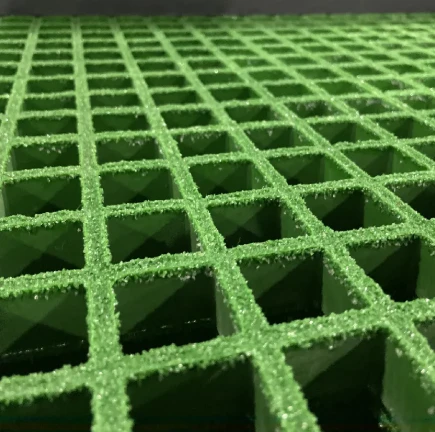

frp micro mesh grating

FRP grating panels have emerged as a revolutionary solution in industrial and commercial settings, offering an unparalleled blend of strength, durability, and versatility. These panels, crafted from fiberglass-reinforced plastic, provide a robust alternative to traditional materials, particularly in environments where safety and longevity are paramount.

Trustworthiness of FRP grating panels stems from rigorous testing and certification processes conducted by industry-standard organizations. These panels often meet or exceed national and international standards such as ASTM, ISO, and OSHA, providing end-users with reassurance of their safety and functionality. Many users have reported enhanced workplace safety, citing the anti-slip surfaces and fire-retardant properties of FRP panels as contributing factors to a significant reduction in workplace accidents. Beyond these technical attributes, the installation and maintenance experience with FRP grating panels further solidifies their status as a preferred choice for many businesses. Installation is straightforward, often requiring less manpower and time compared to metallic or concrete alternatives. The panels can be easily cut to size using standard tools, providing flexibility during installation and accommodating custom designs. Maintenance is equally convenient, primarily due to the panels’ resistance to environmental wear and tear. Regular cleaning with basic detergents is typically sufficient, keeping surfaces clean and free from debris that might cause potential hazards. This ease of maintenance ensures that facilities can sustain operations without frequent interruptions, thereby optimizing productivity. In conclusion, FRP grating panels offer a compelling combination of durability, performance, and practicality that is well-suited to a wide range of industrial applications. Their corrosion resistance, structural strength, authoritative backing, and trustworthy certification make them an ideal choice for any facility aiming to enhance safety while reducing long-term operational costs. As industries continue to evolve, FRP grating panels stand at the forefront of innovative material solutions, embodying a commitment to safety and efficiency that echoes the demands of modern engineering.

Trustworthiness of FRP grating panels stems from rigorous testing and certification processes conducted by industry-standard organizations. These panels often meet or exceed national and international standards such as ASTM, ISO, and OSHA, providing end-users with reassurance of their safety and functionality. Many users have reported enhanced workplace safety, citing the anti-slip surfaces and fire-retardant properties of FRP panels as contributing factors to a significant reduction in workplace accidents. Beyond these technical attributes, the installation and maintenance experience with FRP grating panels further solidifies their status as a preferred choice for many businesses. Installation is straightforward, often requiring less manpower and time compared to metallic or concrete alternatives. The panels can be easily cut to size using standard tools, providing flexibility during installation and accommodating custom designs. Maintenance is equally convenient, primarily due to the panels’ resistance to environmental wear and tear. Regular cleaning with basic detergents is typically sufficient, keeping surfaces clean and free from debris that might cause potential hazards. This ease of maintenance ensures that facilities can sustain operations without frequent interruptions, thereby optimizing productivity. In conclusion, FRP grating panels offer a compelling combination of durability, performance, and practicality that is well-suited to a wide range of industrial applications. Their corrosion resistance, structural strength, authoritative backing, and trustworthy certification make them an ideal choice for any facility aiming to enhance safety while reducing long-term operational costs. As industries continue to evolve, FRP grating panels stand at the forefront of innovative material solutions, embodying a commitment to safety and efficiency that echoes the demands of modern engineering.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025