loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Micro Mesh Grating: Anti-Slip, Corrosion-Resistant

frp micro mesh grating,frp platform grating,frp protruded grating is a key solution in the manufacturing industry, specifically within plastic product industry and Enhance the manufacturing of plastic products. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- frp micro mesh grating,frp platform grating,frp protruded grating Overview

- Benefits & Use Cases of frp micro mesh grating,frp platform grating,frp protruded grating in Enhance the manufacturing of plastic products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on frp micro mesh grating,frp platform grating,frp protruded grating from Zhaojia Composites Co., Ltd

frp micro mesh grating,frp platform grating,frp protruded grating Overview

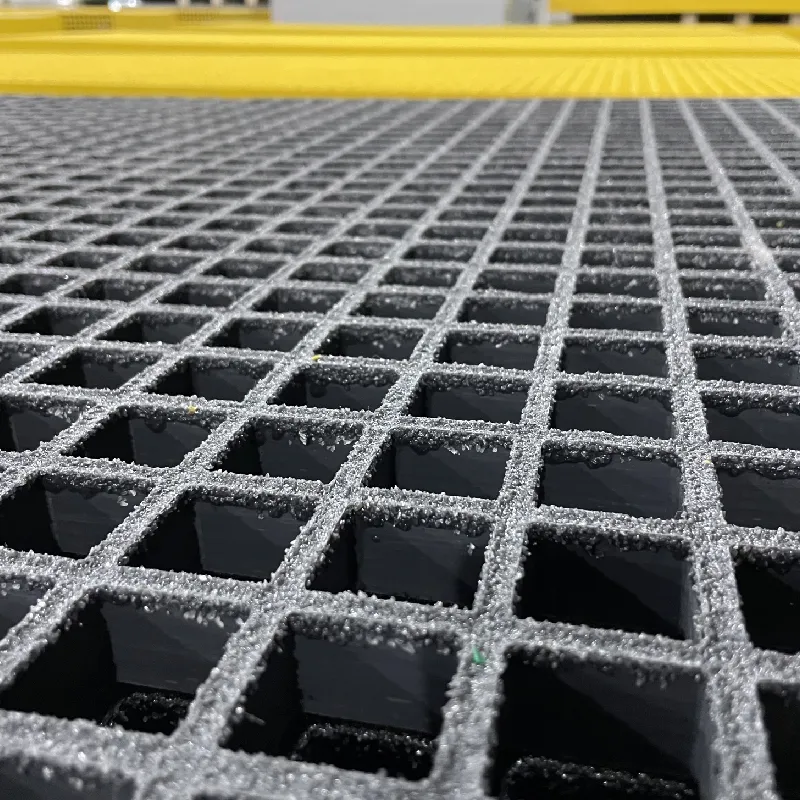

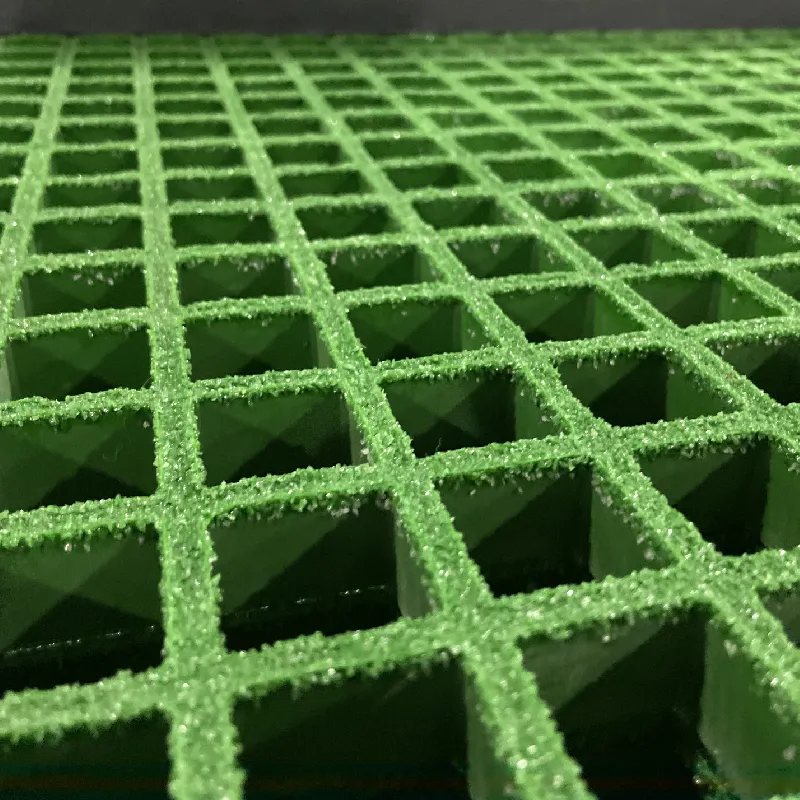

FRP gratings are engineered, fiber-reinforced polymer panels designed for load-bearing surfaces in corrosive, wet, or electrically sensitive environments. In the plastic product industry, these solutions improve worker safety, protect equipment, and streamline plant layouts. Zhaojia Composites Co., Ltd manufactures three high-demand formats—frp micro mesh grating (tight apertures for heel-safe, tool-drop prevention and splash reduction), frp platform grating (molded panels with multi-directional strength for walkways, mezzanines, and sumps), and frp protruded grating (pultruded “I” or “T” bars for long spans and higher load ratings).

Technically, molded FRP gratings deliver isotropic strength and excellent chemical resistance, while protruded FRP gratings provide superior unidirectional stiffness for heavy-duty platforms. Typical options include grit or concave anti-slip surfaces, conductive or non-conductive systems, UV inhibitors, and resin choices tailored to exposure (e.g., general-purpose, isophthalic, or vinyl ester for aggressive chemicals). Zhaojia Composites emphasizes consistent resin-glass ratios, dimensional accuracy, and robust surface finishing to meet common industry guidelines for safety and durability. For B2B buyers, the result is a predictable, fit-for-purpose product line that integrates into new builds or retrofits with minimal disruption.

Benefits & Use Cases of frp micro mesh grating,frp platform grating,frp protruded grating in Enhance the manufacturing of plastic products

Plastic manufacturing environments face frequent washdowns, chemical exposure, and shifting process layouts. FRP platform grating excels in production walkways, mezzanines, tank surrounds, and trench covers, providing high slip resistance and corrosion-proof performance without the repaint cycles associated with metal. frp micro mesh grating is selected where small-part retention and heel safety matter—around precision assembly zones, QC labs, or elevated platforms above water and chemical treatment areas—reducing splash-through and improving housekeeping. For heavy loads, long span platforms, and equipment access near extruders or molding presses, frp protruded grating supplies the stiffness and deflection control needed to keep operations stable.

Key advantages for B2B decision makers include lightweight panels that simplify installation, dielectric properties that enhance electrical safety, and consistent performance in humid, saline, or chemically active atmospheres. Zhaojia Composites Co., Ltd supports tailored specifications—panel sizes, surface finishes, clips, and handrail integration—so plant engineers can standardize platforms and walkways across multiple facilities. Their application experience in plastics processing translates to practical guidance on resin selection, product thickness, and support spacing, helping teams accelerate project timelines while safeguarding operators and equipment.

Cost, Maintenance & User Experience

Total cost of ownership favors FRP over galvanized or painted steel in many plastic manufacturing facilities. While initial material costs can be comparable, lifecycle savings accrue from corrosion resistance, no-paint requirements, and reduced shutdowns for maintenance. FRP’s light weight minimizes installation labor and lifting equipment needs; standardized panel sizes and clip systems further shorten install time. Over years of service, frp platform grating and frp protruded grating typically retain surface friction and structural integrity without frequent recoating, while frp micro mesh grating reduces debris fall-through that can cause downstream clean-up costs.

Customer feedback from the plastic product industry highlights three recurring outcomes: improved slip safety in wet areas, fewer corrosion-related interventions near chemical storage and water treatment, and smoother audits due to neat, durable walking surfaces. Maintenance teams appreciate the ease of cleaning and the absence of rust flakes that can contaminate product zones. Buyers also note faster expansions and reconfigurations—panels can be cut on-site and re-deployed as layouts evolve. Zhaojia Composites Co., Ltd backs these user benefits with responsive pre- and post-sales support, helping facilities plan for load classes, support framing, and anchoring to achieve target ROI.

Sustainability & Market Trends in manufacturing

Manufacturing leaders are aligning capital projects with sustainability and safety targets. FRP gratings contribute by extending service life, reducing repainting and solvent use, and enabling lighter structures that can cut transport emissions. In many regions, regulators and EHS teams are also prioritizing slip resistance, corrosion control, and electrical safety—areas where frp micro mesh grating, frp platform grating, and frp protruded grating deliver consistent performance. As composite adoption grows across industrial flooring, B2B buyers value suppliers that balance mechanical performance with responsible production practices.

Zhaojia Composites Co., Ltd is advancing this trajectory with material optimization, efficient curing processes, and careful surface finishing that enhances longevity. The company’s consultative approach helps engineers specify the right resin systems and surface textures to extend replacement cycles and reduce waste. Market momentum is shifting toward standardizing FRP on platforms, walkways, and access points in plastics plants—driven by lower lifecycle impacts, improved worker protection, and the ability to configure systems around evolving processes without scrapping corroded steel.

Conclusion on frp micro mesh grating,frp platform grating,frp protruded grating from Zhaojia Composites Co., Ltd

For plastic manufacturing facilities, FRP gratings deliver a compelling blend of safety, durability, and long-term value. Whether you need heel-safe frp micro mesh grating, versatile frp platform grating, or heavy-duty frp protruded grating, Zhaojia Composites Co., Ltd provides reliable, application-driven solutions that stand up to chemicals, moisture, and constant traffic. Partner with a team that understands your production environment and supports fast, clean installations.

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025