loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

helmi . 08, 2025 04:15

Back to list

frp micro mesh grating

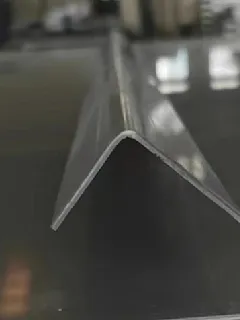

Floor grating clamps are a crucial element in industrial and commercial flooring solutions. These clamps serve an essential role in maintaining both safety and functionality. Building on genuine experience in the field, these insights outline the necessity, components, selection, installation, and maintenance of floor grating clamps. This detailed exploration will assist decision-makers in choosing the most suitable clamps while ensuring adherence to industry standards.

Proper maintenance is just as important as proper installation. Regular checks should be performed to identify any signs of wear, corrosion, or slippage. This proactive approach involves inspecting clamps for tightness and alignment, ensuring bolts and fixing elements have not loosened over time due to vibration or load stresses. If issues are detected, timely replacement or tightening can prevent more significant failures and extend the lifespan of the grating system. Incorporating advanced technology and innovation into floor grating clamp systems can further enhance their efficiency and reliability. Innovations such as adjustable clamps have emerged, offering adaptability to various grating sizes and configurations. Additionally, coatings that exceed traditional galvanization have been developed to provide even greater resistance to harsh environmental factors, thereby reducing long-term maintenance needs and costs. Relying on authoritative sources and industry standards ensures that choices made regarding floor grating clamps adhere to best practices. Consulting with engineers, contractors, or manufacturers who possess authoritative knowledge and vast experience in this niche field can guide optimal product selection and application techniques. Additionally, adhering to certification standards like ISO or OSHA ensures compliance and reinforces trust in the products' safety and effectiveness. Ultimately, trustworthiness in floor grating clamps is built upon a blend of robust materials, precise engineering, and expert installation and maintenance. Engaging with reputable suppliers and contractors who provide warranties and technical support further strengthens this trust. By prioritizing these aspects, stakeholders can ensure a safe, durable, and compliant flooring solution tailored to their specific environment and operational needs. In summary, floor grating clamps are indispensable for any operation that prioritizes safety and efficiency in its flooring systems. By focusing on the experience, professional expertise, authoritative guidance, and trustworthy practices, businesses can confidently implement these components, ensuring stability and safety across their facilities. This strategic approach not only optimizes performance but also contributes to overall operational excellence.

Proper maintenance is just as important as proper installation. Regular checks should be performed to identify any signs of wear, corrosion, or slippage. This proactive approach involves inspecting clamps for tightness and alignment, ensuring bolts and fixing elements have not loosened over time due to vibration or load stresses. If issues are detected, timely replacement or tightening can prevent more significant failures and extend the lifespan of the grating system. Incorporating advanced technology and innovation into floor grating clamp systems can further enhance their efficiency and reliability. Innovations such as adjustable clamps have emerged, offering adaptability to various grating sizes and configurations. Additionally, coatings that exceed traditional galvanization have been developed to provide even greater resistance to harsh environmental factors, thereby reducing long-term maintenance needs and costs. Relying on authoritative sources and industry standards ensures that choices made regarding floor grating clamps adhere to best practices. Consulting with engineers, contractors, or manufacturers who possess authoritative knowledge and vast experience in this niche field can guide optimal product selection and application techniques. Additionally, adhering to certification standards like ISO or OSHA ensures compliance and reinforces trust in the products' safety and effectiveness. Ultimately, trustworthiness in floor grating clamps is built upon a blend of robust materials, precise engineering, and expert installation and maintenance. Engaging with reputable suppliers and contractors who provide warranties and technical support further strengthens this trust. By prioritizing these aspects, stakeholders can ensure a safe, durable, and compliant flooring solution tailored to their specific environment and operational needs. In summary, floor grating clamps are indispensable for any operation that prioritizes safety and efficiency in its flooring systems. By focusing on the experience, professional expertise, authoritative guidance, and trustworthy practices, businesses can confidently implement these components, ensuring stability and safety across their facilities. This strategic approach not only optimizes performance but also contributes to overall operational excellence.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025