loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

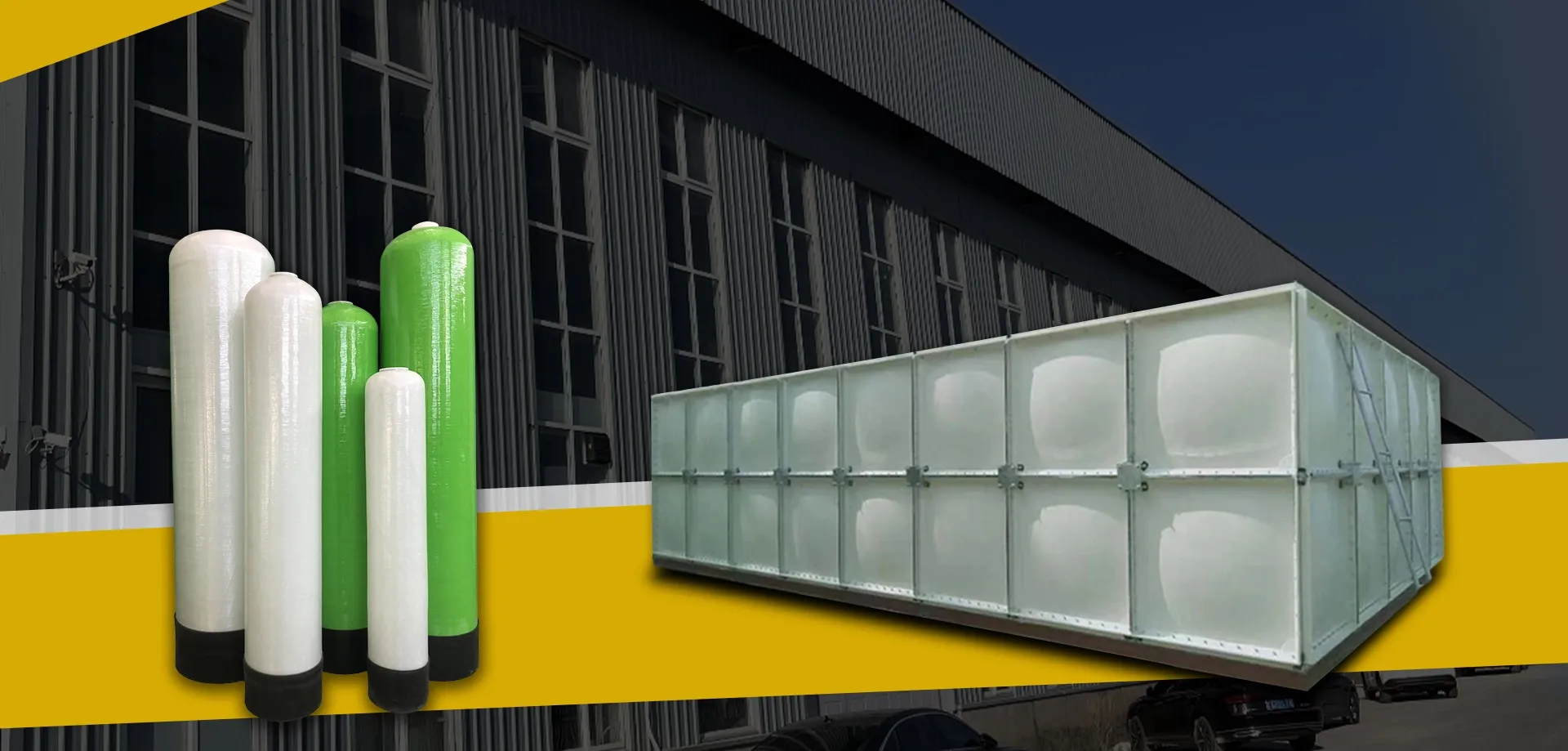

1054 frp vessel

The Advancements and Applications of 1054% FRP Vessels

In recent years, the evolution of materials technology has ushered in significant advances in various industries. One notable development is the use of Fiber-Reinforced Polymer (FRP) vessels, specifically those with a composition denoted as 1054% FRP. These innovative vessels are increasingly being utilized in sectors such as chemical processing, marine, water treatment, and storage industries due to their remarkable properties.

Understanding FRP Technology

Fiber-Reinforced Polymers are composite materials made by combining a polymer matrix with fiber reinforcements, which can include glass, carbon, or aramid fibers. The primary aim of this combination is to enhance the mechanical properties of the polymer, providing increased strength, durability, and resistance to environmental conditions. The term 1054% FRP typically indicates a specific ratio or formulation of fibers and resins that optimize the structural integrity and performance characteristics of the vessel.

FRP materials stand out for their exceptional strength-to-weight ratio. This property is particularly beneficial when considering the operational demands placed on vessels in various applications. For instance, lighter vessels can lead to reduced transportation costs and increased efficiency in handling.

Advantages of 1054% FRP Vessels

1. Corrosion Resistance One of the most significant advantages of 1054% FRP vessels is their innate resistance to corrosion. In industries such as chemical processing, where aggressive chemicals are regularly stored or transported, the use of metallic vessels can lead to rapid deterioration. In contrast, FRP vessels offer superior protection against such corrosive environments, thereby extending their lifespan and reducing maintenance costs.

2. Lightweight and Structural Efficiency The lightweight nature of 1054% FRP vessels makes them easier to transport and install than traditional metal vessels. This not only simplifies logistics but also reduces the structural requirements for supports and foundations, ultimately lowering the overall project costs.

1054 frp vessel

3. Thermal Insulation FRP materials have excellent thermal insulation properties, which is essential for specific applications where temperature control is crucial. This capability can help in maintaining desired temperatures for sensitive materials, preventing thermal shock, and ensuring stability during storage and transport.

4. Customization and Design Flexibility FRP technology allows for a high degree of customization in design, enabling manufacturers to produce vessels tailored to the specific needs of different industries. This flexibility can lead to creative solutions for complex engineering problems, facilitating innovation in vessel design and functionality.

Applications of 1054% FRP Vessels

The applications of 1054% FRP vessels are vast and varied. In the chemical industry, these vessels are used for storing corrosive chemicals safely and efficiently. The oil and gas sector employs FRP vessels for liquid storage due to their resistance to harsh environmental conditions.

In the marine industry, the lightweight nature of FRP presents significant advantages in terms of fuel efficiency and performance for shipping and boating applications. Additionally, FRP vessels are gaining traction in water treatment facilities, where they can store and process wastewater because of their resistance to chemicals and environmental wear.

Future Prospects

The future of 1054% FRP vessels appears bright as ongoing research and development continue to refine the technology. Advances in manufacturing processes, such as resin transfer molding and automated fiber placement, are likely to lower production costs and improve the performance characteristics of these vessels. Furthermore, as sustainability becomes increasingly important across industries, FRP's recyclability and lower energy requirements for manufacturing make it an attractive alternative to traditional materials.

In conclusion, 1054% FRP vessels epitomize the advancements within materials science, offering unparalleled benefits across various sectors. Their unique combination of strength, lightweight, and corrosion resistance positions them as a preferred choice for modern industrial applications. As the demand for efficient and sustainable solutions continues to rise, FRP technology will likely play a pivotal role in shaping the future landscape of storage and transportation solutions.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025