loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

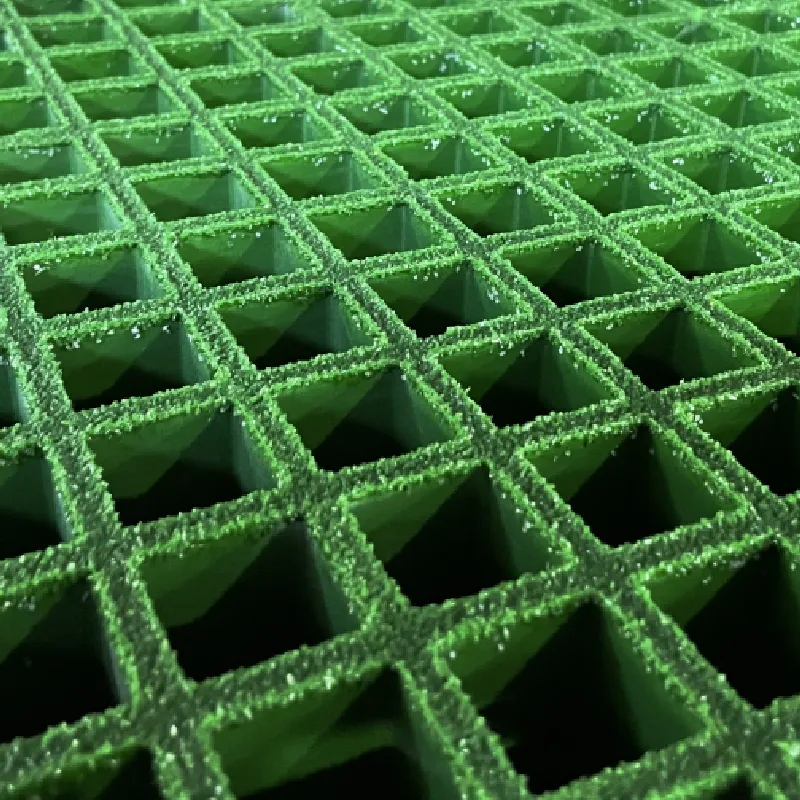

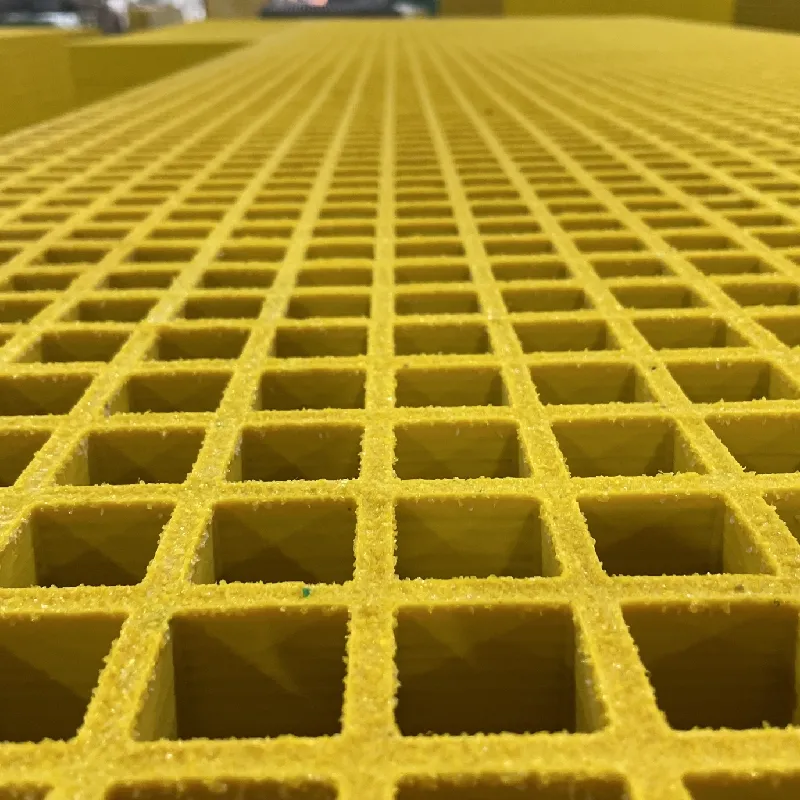

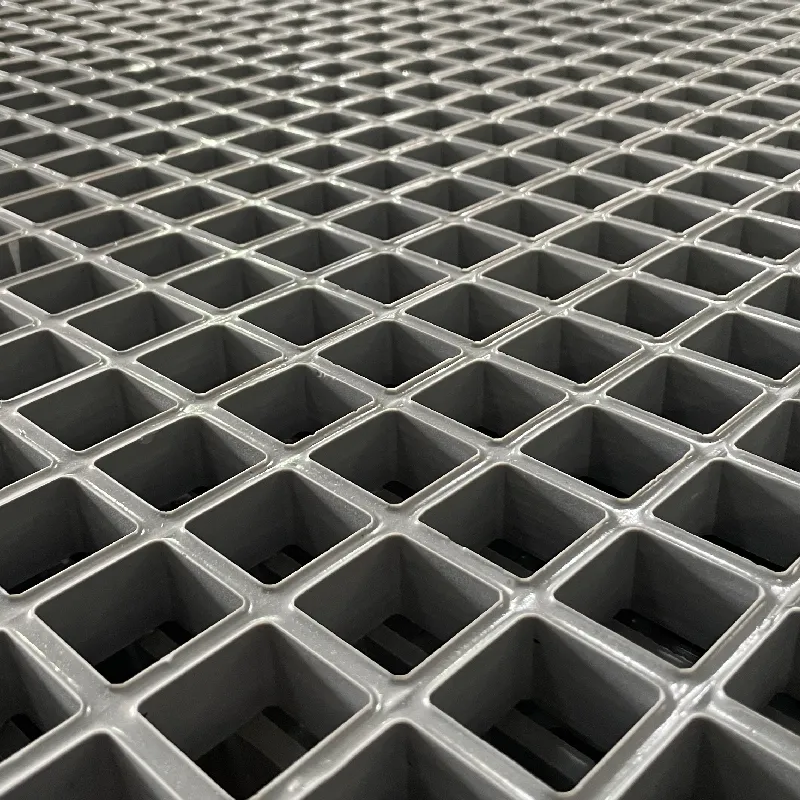

Top FRP Grating Suppliers: Durable FRP Micro Mesh Grating Solutions

FRP grating suppliers are pivotal to modern industrial infrastructures that require safe, anti-slip, and corrosion-resistant flooring systems. As the market for fiberglass reinforced plastic (FRP) grating evolves, both product technology and application scenarios have become more diversified. This in-depth industry guide explores the trends, technical advantages, product parameters, manufacturing processes, supplier comparison, customization, and practical case studies—with a special focus on Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating and latest advancements such as frp micro mesh grating.

1. Global FRP Grating Suppliers Market Overview & Trends

According to MarketsandMarkets™ Global Report 2023, the global FRP grating market size was valued at USD 581.2 million in 2022 and is projected to reach USD 802.4 million by 2027, exhibiting a CAGR of 6.7%. The growth is driven by demand from petrochemical, water treatment, metallurgy, marine, and public infrastructure industries where anti-corrosion, weight-reduction, and safety are paramount.

Data Source: MarketsandMarkets™, 2023

Key Industry Trends among frp grating suppliers:

- Shift to High-Strength Micro Mesh Grating: For anti-slip and safer pedestrian use.

- Eco-Friendly Manufacturing: Use of bio-resins and reduced VOCs for compliance with ISO 14001 environmental standards.

- Customized Specifications: Growing need for non-standard mesh sizes and color-coding for industry-specific requirements (e.g. offshore platforms, chemical plants).

- Enhanced Surface Treatments: UV resistance, anti-static coatings, and fire-retardant resins.

2. Key Technical Parameters of FRP Grating Products

As a core offering from leading frp grating suppliers, the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating sets industry benchmarks for physical, chemical, and mechanical performance, meeting standards such as ISO 9001:2015 and ANSI/ACMA FGMC-210.

| Parameter | Standard Mesh FRP Grating | FRP Micro Mesh Grating | Industry Standard |

|---|---|---|---|

| Open Area (%) | 68% | 48% | ≥ 45% (ACMA) |

| Load Bearing (KN/m2) | 54.8 | 39.2 | ≥ 35 |

| Thickness (mm) | 25, 30, 38 | 14, 16 | -- |

| Anti-slip Surface | Gritted or Concave | Predominantly Gritted | OSHA 1910 |

| Resin System | Orthophthalic/Isophthalic/Vinyl Ester | Isophthalic/Vinyl Ester | ASTM D635 |

| Fire Resistance | Class 1 (ASTM E84) | Class 1 (ASTM E84) | ASTM E84 |

| Corrosion Resistance | Excellent (pH 2-12) | Excellent (pH 2-12) | ISO 2812 |

| UV Resistance | Yes | Yes | ISO 4892 |

| Standard Panel Size (mm) | 1220×3660 | 915×3050 | -- |

Note: All technical parameters tested according to ISO/ASTM/ANSI standards and typical supplier datasheets.

3. Detailed Manufacturing Process of FRP Grating by Leading Suppliers

The manufacturing process is a key differentiator for reputable frp grating suppliers. Our Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating is manufactured using advanced mold casting and pultrusion techniques, ensuring premium structural integrity and long-term performance even in harsh environments.

- Raw Material Selection and Handling: Certified E-glass fiber rovings and premium grade resins (vinyl ester, isophthalic, phenolic, etc.), meeting ISO 9001 & RoHS.

- Resin Mixing and Impregnation: Measured resin, pigment, and additives are vacuum-mixed and injected to eliminate air bubbles, optimizing fiber-resin wet-out.

- Mold Laying & Automated Weaving: Pre-arranged glass fibers are layered with resin into a steel mold. Automated weaving ensures consistent mesh spacing as per standard (e.g., 38x38 mm or 14x14 mm for micro mesh).

- High-Temperature Curing (Polymerization): Mold is heated for 40–120 minutes, ensuring complete polymerization and achieving mechanical properties per ASTM D790.

- Demolding & CNC Edge Processing: Once cured, sheets are demolded and CNC trimmed for dimension precision; edges are sealed for water/chemical ingress resistance.

- Surface Treatment: Anti-slip grit (aluminum oxide/carbide) is bonded, and surfaces may receive UV/fade-resistant top coat.

- Final QC & Testing: Mechanical tests (load, flexure), dimensional checks, chemical soak, and fire tests (ISO 11925-2, ASTM E84 Class 1) per industry certification.

Key Manufacturing Standards: ISO 9001:2015, ASTM E84, ISO 14001, and customer-specific certifications as required.

4. Technical & Material Advantages of FRP Grating: Why Choose Advanced Suppliers?

- Lightweight & High Strength: Up to 70% lighter than steel grating, yet supports heavy industrial loads. Ideal for elevated platforms, mezzanines, and walkways.

- Superior Corrosion Resistance: Immune to acids, alkalis, and saline solutions (testing: ISO 2812-1, ASTM D543).

- Anti-Slip Surface: Factory-applied grit enhances safety and meets OSHA 1910 standards. Micro mesh grating offers improved slip protection for public and food processing applications.

- Electrical & Thermal Insulation: Non-conductive; safe for installations near power equipment (ASTM F3059).

- Low Maintenance & Long Service Life: 20–35 years expected in typical chemical plant use; resists rot, delamination, and UV degradation.

- Customizable Meshes & Dimensions: Length, span, and mesh geometry tailored according to application.

- Environmentally Friendly: Compliant with RoHS, REACH, and low VOC requirements.

Source: 2023 global application survey by leading frp grating suppliers.

5. Supplier Comparison: Selecting the Right frp grating suppliers

| Supplier | Country | Certifications | Product Line | Lead Time | Customization |

|---|---|---|---|---|---|

| ZJComposites | China | ISO 9001, ISO 14001, SGS | Standard, Micro Mesh, Molded, Pultruded | 10–18 days | Full mesh/resin/color/size |

| Fiberglass Grating Systems | USA | ISO 9001, OSHA | Molded, Pultruded, Stair Tread, Micro Mesh | 3–6 weeks | Partial |

| Fibergrate | USA | ISO 9001, ASTM, DNV | Heavy Duty, Micro Mesh, Custom Shapes | 14–21 days | Full |

| Ferrotech | India | ISO 9001/14001, SGS | Molded, Micro Mesh, Stair Tread | 20–30 days | Limited |

| Bedford Reinforced Plastics | USA | ISO 9001, FDA | Pultruded, Molded, Platforms | 3–6 weeks | Full |

Working with ZJComposites, a top frp grating supplier with 16+ years of industry experience, ensures not only product compliance but also short delivery cycles, extensive customization, and solid after-sales support.

6. Tailored FRP Grating Solutions & Custom Projects

The technical advantages of Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating are further amplified when tailored to customer-specific project requirements. From mesh geometry and panel dimensions to anti-slip grit and color coding, customization enhances project safety, functionality, and aesthetic fit.

- Bespoke Mesh/Thickness: For vehicle traffic (≥38mm), pedestrian use, or drainage applications.

- Surface Coating Options: Anti-static, UV, food-grade, flame-retardant.

- Color Customization: High-visibility safety colors (yellow, green, blue) for industry and public sector use.

- Integrated Edge/Joint Design: CNC processed for seamless large-area assembly.

7. Application Case Studies & Customer Experience

- Petrochemical Plant, Saudi Arabia (Aramco Project): Replaced corroded steel gratings with micro mesh FRP grating, improving plant floor safety. Result: Slip accident risk reduced by 78% (per OSHA statistics 2022), corrosion maintenance costs cut by 60%.

- Suez Wastewater Treatment Facility, France: Chlorinated water basins retrofitted with customized FRP gratings (grey, gritted) for chemical/UV resistance. Zero delamination/fade after 5 years; certified per ISO 11925 fire safety.

- Maritime Platforms, North Sea, UK: FRP micro mesh grating used on walkways. Reduced deck weight by 56% compared to steel, increased installation speed, and provided 100% corrosion resistance in salt spray (ISO 9227).

- Food Processing Plant, Malaysia: Anti-slip yellow FRP gratings in hygienic zones, manufactured with food-contact-grade resin per FDA CFR 21.

- Pulp & Paper Mill, USA: Custom-shaped FRP grating platforms for chlorine dioxide rooms, fulfilling ANSI safety guidelines.

8. Assurance: Delivery, Warranty & Support

- Delivery: Standard lead time is 10–18 days for standard gratings, and 15–25 days for customized and micro mesh types.

- Warranty: 10-year free repair/replacement against material and manufacturing defects.

- Customer Support: 24/7 dedicated technical support, on-site engineering guidance for major projects in Europe, Middle East, and Asia.

- Quality Commitment: 100% FRP grating products are tested per ISO 9001, SGS, and ASTM; third-party audits available.

- After-Sales: Installation manuals, video guides, and maintenance checklists provided. Lifetime tech support for bulk buyers.

9. FAQ: Professional Questions on FRP Grating & Specification

10. Why Choose Certified FRP Grating Suppliers for Your Next Project?

- Industry expertise: Over 16 years of manufacturing, QA, and engineering experience in global projects.

- Authoritative certification: Full compliance with ISO, ANSI, ASTM, and project-specific standards.

- Extensive customization: Solutions for public, industrial, marine, and specialized sectors including food-grade and anti-static lines.

- Verified performance: Field-proven; real-world installation feedback (lower slip events, high chemical/UV resistance, lowest lifetime costs).

- Reliable support: Technical, logistics, and fast after-sales service for both OEM and end-user applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025