loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Urt . 14, 2025 10:17

Back to list

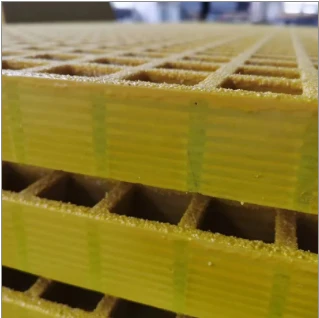

frp micro mesh grating

Galvanized floor grating is an essential component in industrial and commercial construction, providing robust support and exceptional safety. Over the years, its use has expanded from traditional industrial applications to more innovative uses in residential and commercial spaces, testament to its versatility and durability.

Experience garnered through years of practical application highlights the material’s versatility—grating is not just confined to industrial walkways but is also found in public infrastructure projects, such as bridge decks and metro staircases. In more creative applications, galvanized grating serves as a striking aesthetic feature in architectural designs, providing decorative facades or dynamic flooring solutions that allow for drainage and airflow. Each installation case enhances the credibility of galvanized grating as a multifaceted building material. One cannot overstate the importance of trust when selecting construction materials, and galvanized floor grating consistently meets expectations in performance and longevity. Site managers and contractors favor it for its quick installation and adaptability to various design challenges, which translates to cost efficiency and time savings. Furthermore, the grating’s low maintenance requirement—owing to its anti-corrosive properties—ensures long-term savings while maintaining safety. In conclusion, galvanized floor grating is a benchmark product that exemplifies the harmony of engineering innovation and practical performance. Its diverse applications, combined with its robustness and compliance with safety standards, make it a valuable asset in both commercial and industrial settings. As industries evolve towards sustainability and durability, the demand for reliable materials like galvanized grating will invariably grow, cementing its place as a staple in the toolkit of architects and engineers worldwide.

Experience garnered through years of practical application highlights the material’s versatility—grating is not just confined to industrial walkways but is also found in public infrastructure projects, such as bridge decks and metro staircases. In more creative applications, galvanized grating serves as a striking aesthetic feature in architectural designs, providing decorative facades or dynamic flooring solutions that allow for drainage and airflow. Each installation case enhances the credibility of galvanized grating as a multifaceted building material. One cannot overstate the importance of trust when selecting construction materials, and galvanized floor grating consistently meets expectations in performance and longevity. Site managers and contractors favor it for its quick installation and adaptability to various design challenges, which translates to cost efficiency and time savings. Furthermore, the grating’s low maintenance requirement—owing to its anti-corrosive properties—ensures long-term savings while maintaining safety. In conclusion, galvanized floor grating is a benchmark product that exemplifies the harmony of engineering innovation and practical performance. Its diverse applications, combined with its robustness and compliance with safety standards, make it a valuable asset in both commercial and industrial settings. As industries evolve towards sustainability and durability, the demand for reliable materials like galvanized grating will invariably grow, cementing its place as a staple in the toolkit of architects and engineers worldwide.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025