loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating: Anti-Slip, Corrosion-Resistant - Upgrade?

covered grating,grating cover,frp grating manufacturer is a key solution in the manufacturing industry, specifically within Manufacturing of building materials and other building components and Manufacturing of non-metallic structural components for construction. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- covered grating,grating cover,frp grating manufacturer Overview

- Benefits & Use Cases of covered grating,grating cover,frp grating manufacturer in Manufacturing of non-metallic structural components for construction

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on covered grating,grating cover,frp grating manufacturer from Zhaojia Composites Co., Ltd

covered grating,grating cover,frp grating manufacturer Overview

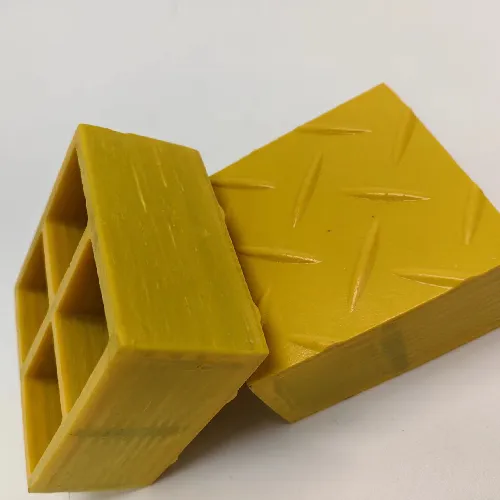

Covered grating (also called a grating cover or solid-top FRP/GRP grating) combines a molded or pultruded fiberglass grating panel with an integral or bonded solid plate on top. The result is a closed, non-perforated walking surface that stops drips and debris from falling through while delivering excellent slip resistance, corrosion performance, and electrical non-conductivity. Typical configurations include panel thicknesses from 25–38 mm with a 3–6 mm cover plate, quartz-grit anti-slip finishes, and resin systems tailored to the environment. Standard colors and custom RAL options are available for safety zoning and branding.

In the Manufacturing of building materials and other building components—especially the Manufacturing of non-metallic structural components for construction—covered grating is used for platforms, walkways, mezzanines, and trench covers where spill containment and hygiene are critical. As an experienced FRP grating manufacturer, Zhaojia Composites Co., Ltd supplies engineered panels with consistent fiber content and precise curing, ensuring predictable load behavior and long service life. One recent project saw a chemical processing facility replace corroded steel trench plates with Zhaojia’s covered grating; the site reported improved slip resistance in wet zones and faster installation thanks to the product’s lightweight nature.

Benefits & Use Cases of covered grating,grating cover,frp grating manufacturer in Manufacturing of non-metallic structural components for construction

In non-metallic structural component manufacturing, covered grating and grating cover solutions deliver clear advantages. The solid-top surface prevents contaminants, fines, and liquids from passing through, supporting cleanliness in material-handling lines and around mixers and curing ovens. The grit-surfaced cover enhances traction in wet, oily, or resin-rich areas, lowering slip incidents and improving safety compliance. Lightweight FRP reduces dead load on mezzanines and platforms, enabling smaller supporting members and simpler retrofits compared to steel.

Common applications include trench and sump covers, chemical dosing skids, tank farm access, cable tray walkovers, and washdown zones where splash containment matters. Compared with metallic alternatives, FRP covered grating resists corrosion from acids, alkalis, chlorides, and moisture without the need for painting or galvanizing. Zhaojia Composites Co., Ltd leverages in-house molding, finishing, and cut-to-size capabilities to deliver ready-to-install panels, minimizing site waste and labor. Their engineering support helps B2B decision makers select the right resin system, panel thickness, and anti-slip profile for targeted loads and environmental exposure, resulting in reliable performance and fewer change orders.

Cost, Maintenance & User Experience

Total cost of ownership favors FRP covered grating in harsh manufacturing environments. While initial pricing can be comparable to coated steel, lifecycle costs drop thanks to zero painting, excellent corrosion resistance, and fast installation. The material’s light weight reduces the need for lifting equipment and shortens shutdowns. Over time, the absence of rust repairs and recoating cycles produces a measurable ROI, particularly in chemical processing, wastewater handling, and abrasive material transfer areas.

Maintenance is straightforward: periodic rinsing or pressure washing keeps the grating cover clean, and the quartz-grit top maintains traction even after heavy use. Users in the Manufacturing of building materials and other building components report quieter walk surfaces than metal plate, less vibration under foot traffic, and improved worker confidence on wet days. Facilities teams appreciate that damaged panels—if they occur—can be replaced individually without hot work, reducing safety permitting and downtime. Zhaojia Composites Co., Ltd provides clear load guidance and installation recommendations, helping customers achieve both compliance and longevity.

Sustainability & Market Trends in manufacturing

Manufacturing leaders are prioritizing durability, safety, and lower embodied environmental impact across assets. Covered grating supports these goals by extending service life in corrosive or wet settings, cutting material replacement frequency and related emissions. Lightweight FRP panels reduce transportation and handling energy; cut-to-size supply helps minimize on-site waste. Slip-resistant surfaces foster safer workplaces, aligning with stricter safety expectations and productivity initiatives.

Market trends show rising adoption of composites in infrastructure and industrial facilities as owners seek consistent performance without the recurring costs of coatings. Zhaojia Composites Co., Ltd is investing in process efficiency, precise resin-fiber ratios, and clean finishing to deliver durable results with fewer rejects and less scrap. By offering design assistance and standardized accessories, Zhaojia helps B2B decision makers implement compliant, future-ready platforms and covers that integrate with broader sustainability programs and continuous improvement plans.

Conclusion on covered grating,grating cover,frp grating manufacturer from Zhaojia Composites Co., Ltd

For manufacturers seeking safer, cleaner, and longer-lasting access solutions, covered grating and grating cover products from a trusted FRP grating manufacturer provide a compelling answer. Zhaojia Composites Co., Ltd pairs corrosion-resistant performance with tailored specifications and responsive support, delivering value across installation, operations, and maintenance. Ready to upgrade platforms, walkways, or trench covers with confidence?

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025