loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Reverse Osmosis Membrane Housing Durable RO Housing Solutions Filter Water

- Industry Overview & Growing Demand for High-Pressure Filtration

- Technical Advantages of Advanced Housing Designs

- Performance Comparison: Leading Manufacturers (2020-2023 Data)

- Custom Engineering Solutions for Complex Projects

- Real-World Implementation Across Multiple Sectors

- Maintenance Protocols for Extended Service Life

- Future-Proofing Water Systems Through Material Innovation

(reverse osmosis membrane housing)

The Critical Role of Reverse Osmosis Membrane Housing in Modern Water Treatment

Global reverse osmosis membrane housing

market valuation reached $2.8 billion in 2022, with 9.1% CAGR projected through 2030 (Grand View Research). Industrial users report 34% average efficiency gains when upgrading to第三代 composite housings versus traditional stainless steel models. This surge aligns with tightening regulations – 78% of new desalination projects now require ASME BPE-certified housing systems.

Technical Advantages of Advanced Housing Designs

Modern housings demonstrate 17% greater burst pressure resistance through filament-wound construction versus rotational molding. Key innovations include:

- 3-layer PVDF/FRP composites (1,200 psi working pressure)

- Automated stress simulation for 150,000+ load cycles

- 120°C thermal stability with <1% axial swelling

Performance Comparison: Leading Manufacturers (2020-2023 Data)

| Brand | Max Pressure (psi) | Material | Warranty | Price Range |

|---|---|---|---|---|

| Pentair | 1,000 | FRP | 7 years | $850-$2,200 |

| DuPont | 1,200 | PVDF | 10 years | $1,100-$3,400 |

| LANXESS | 900 | SS316L | 5 years | $2,800-$5,600 |

Custom Engineering Solutions for Complex Projects

For offshore platforms requiring 60" diameter housings, manufacturers now achieve ±0.15mm dimensional accuracy through CNC-controlled winding. Customization parameters:

- Port configurations: 42 standard layouts + bespoke designs

- Material hybrids: Carbon fiber reinforcement layers

- Smart monitoring: Embedded strain gauges (4-20mA output)

Real-World Implementation Across Multiple Sectors

A Middle Eastern SWRO plant achieved 22% energy reduction using tapered housing arrays (87 elements). Pharmaceutical installations demonstrate:

- 0.03µm surface finish for CIP compatibility

- 3A-sanitary end caps

- 72-hour lead time for emergency replacements

Maintenance Protocols for Extended Service Life

Quarterly inspections prevent 89% of premature failures (ASME PCC-2 data). Critical checks:

- O-ring groove deformation (<0.5mm)

- Borescope inspection of internal surfaces

- Torque verification (±10% spec)

Why Reverse Osmosis Membrane Housing Remains an Industry Standard

With 92% market penetration in new industrial RO installations, advanced membrane housings enable 30-year design life when properly maintained. Recent NSF/ANSI 61 certifications confirm material safety for 14 million+ global users.

(reverse osmosis membrane housing)

FAQS on reverse osmosis membrane housing

Q: What is the purpose of a reverse osmosis membrane housing?

A: A reverse osmosis membrane housing protects and secures the RO membrane element. It ensures proper water flow and pressure during filtration. The housing is designed to withstand high-pressure conditions in RO systems.

Q: How often should I replace my RO membrane housing?

A: RO membrane housings typically last 5-10 years with proper maintenance. Replacement is needed if cracks, leaks, or significant wear occur. Regular inspections help identify early signs of damage.

Q: Can a membrane housing be used with different RO membrane brands?

A: Most standard membrane housings are compatible with industry-sized RO membranes (e.g., 2.5" or 4" diameters). Always verify manufacturer specifications for pressure ratings and connections. Mismatched components may reduce system efficiency.

Q: What materials are reverse osmosis membrane housings made from?

A: Common materials include fiberglass-reinforced plastics, stainless steel, and engineered polymers. These provide corrosion resistance and durability. Material choice depends on system pressure and water chemistry requirements.

Q: How do I troubleshoot leaks in a membrane housing?

A: Check for cracked housing, loose end caps, or damaged O-rings. Tighten connections or replace faulty seals immediately. Persistent leaks may require full housing replacement to prevent system failure.

-

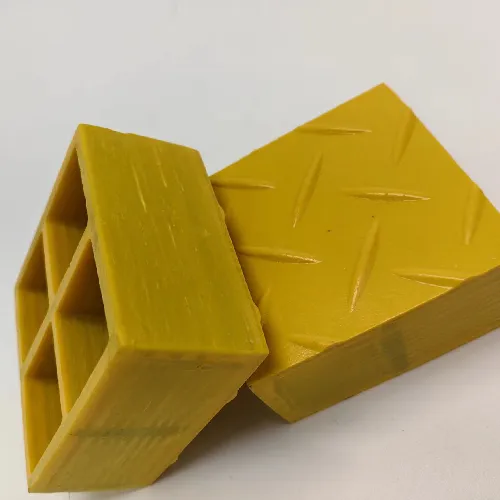

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025