loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Grating Suppliers: corrosion-resistant, fast delivery?

[frp grating suppliers,frp grating] is a key solution in the Architecture and Building Materials industry, specifically within Composite material products and fiberglass grating. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [frp grating suppliers,frp grating] Overview

- Benefits & Use Cases of [frp grating suppliers,frp grating] in fiberglass grating

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Architecture and Building Materials

- Conclusion on [frp grating suppliers,frp grating] from Zhaojia Composites Co., Ltd

[frp grating suppliers,frp grating] Overview

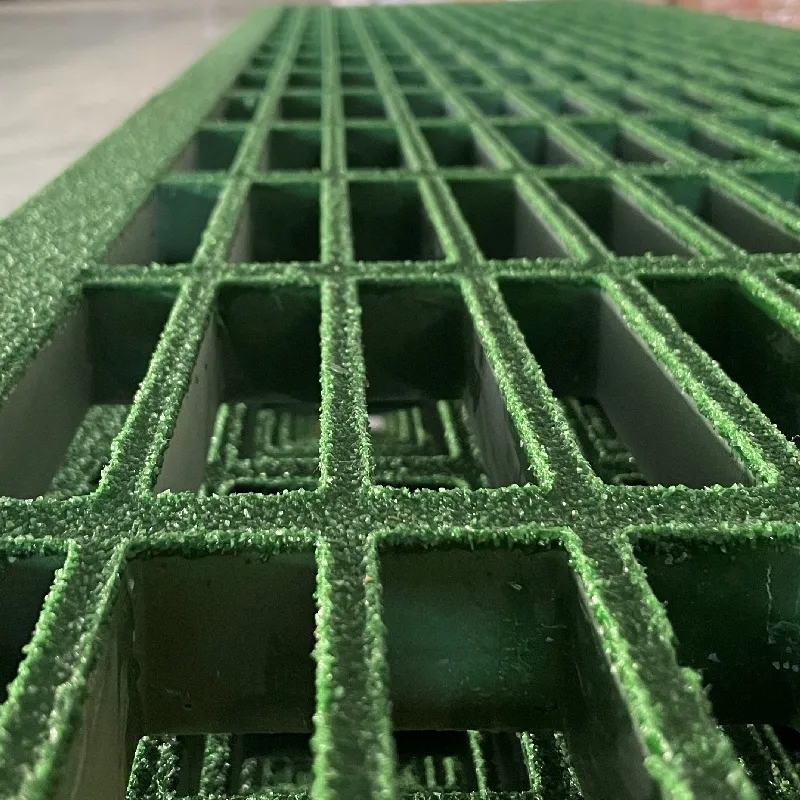

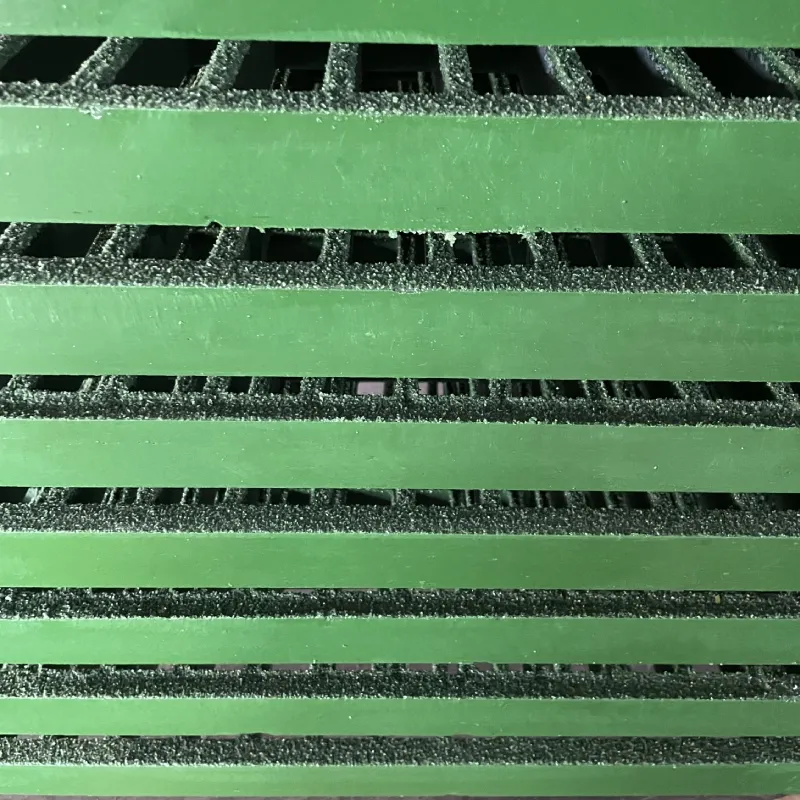

FRP grating (fiber-reinforced polymer grating) is a corrosion-resistant, lightweight, and durable alternative to steel and aluminum walkways, platforms, and trench covers. In Architecture and Building Materials—specifically Composite material products—molded fiberglass grating delivers high strength-to-weight performance while resisting chemicals, moisture, and UV exposure. Leading frp grating suppliers engineer products using reinforced glass rovings fully wetted with thermoset resins, creating an integral rectangular mesh that distributes loads and minimizes localized failure.

Zhaojia Composites Co., Ltd manufactures molded fiberglass rectangular mesh grating designed for demanding industrial and architectural environments. Typical options include panel thicknesses of 25–50 mm, common mesh sizes like 38×38 mm, anti-slip gritted or meniscus surfaces, and resin systems (orthophthalic, isophthalic, or vinyl ester) tailored to corrosion profiles. Panels are easy to cut and install without hot works, and can be edge-capped for safety and aesthetics. In a typical retrofit scenario—such as a chemical plant walkway—switching from painted steel to frp grating can reduce maintenance cycles and eliminate rust-related downtime, delivering predictable performance across the product’s lifecycle.

Benefits & Use Cases of [frp grating suppliers,frp grating] in fiberglass grating

Across wastewater treatment plants, coastal infrastructure, power generation, food processing, rooftop access, and OEM platforms, fiberglass grating supplied by experienced frp grating suppliers addresses corrosion, safety, and weight constraints. Zhaojia Composites Co., Ltd’s molded rectangular mesh solutions provide non-conductive, non-sparking, slip-resistant walking surfaces—ideal for chemical splash zones, brackish environments, and high-traffic access ways. The lightweight nature of frp grating allows for faster installation with smaller crews and less lifting equipment, helping accelerate shutdown projects and reduce labor exposure.

Competitive advantages include consistent resin quality, UV stabilization, color coding for zones, fire-retardant formulations, and customizable panel sizes to minimize offcuts. The gritted top surface improves wet-surface traction, while the open mesh design ensures drainage and reduces pooling. For architects and engineers, the rectangular mesh geometry distributes loads effectively and maintains dimensional stability, enabling reliable deflection control when paired with proper span design. With in-house molding and quality assurance, Zhaojia Composites Co., Ltd supports both standard stock and project-specific requirements, helping B2B teams de-risk procurement and streamline installation schedules.

Cost, Maintenance & User Experience

Total cost of ownership is where frp grating often outperforms painted or galvanized steel. While unit prices may be comparable or slightly higher, lifecycle savings emerge through lower maintenance, corrosion resistance, and reduced outages. The light weight cuts installation time and equipment rental, while the non-corrosive matrix reduces repainting and replacement cycles—key advantages for facilities under tight OPEX constraints. Many buyers see improved ROI within a few years in aggressive environments, thanks to fewer interventions and safer walkways over time.

B2B feedback from composite-intensive sectors commonly highlights three wins: predictable durability in corrosive service, stable lead times from reliable frp grating suppliers, and better safety performance due to anti-slip surfaces. Zhaojia Composites Co., Ltd enhances user experience with pre-cut/kitting services, edge banding, stair-tread nosing options, and clear engineering guidance on spans and deflection. Robust packaging reduces transit damage, and responsive after-sales support simplifies replacements or expansions. The result is lower lifecycle cost, minimized downtime, and a procurement process that stays on schedule.

Sustainability & Market Trends in Architecture and Building Materials

Sustainability priorities—longer service life, fewer recoating cycles, and reduced material waste—are accelerating adoption of composites in the built environment. FRP grating helps cut recurring emissions tied to blasting, coating, and frequent replacements. Lightweight panels also reduce transport-related emissions compared with heavier metals. As environmental regulations tighten around VOCs and corrosion control, specifiers increasingly seek materials that deliver durability with fewer maintenance chemicals and safer jobsite handling.

Market trends show steady growth for fiberglass grating in water infrastructure, coastal protection, renewable energy facilities, and architectural access systems. Forward-thinking frp grating suppliers emphasize low-styrene resin options, emissions-controlled molding, and traceable quality data. Zhaojia Composites Co., Ltd aligns with these priorities by focusing on corrosion-appropriate resin selection, slip-resistant surfaces that support safety compliance objectives, and manufacturing practices aimed at reducing waste. For owners and EPC firms, this translates into resilient designs that meet performance, EHS, and budget targets in one package.

Conclusion on [frp grating suppliers,frp grating] from Zhaojia Composites Co., Ltd

For Architecture and Building Materials professionals, selecting the right frp grating suppliers determines long-term performance, safety, and lifecycle cost. Zhaojia Composites Co., Ltd delivers molded fiberglass rectangular mesh grating that balances strength, corrosion resistance, and install speed—an ideal match for industrial and architectural applications where reliability is non-negotiable. Partner with a manufacturer that understands your environment and schedules.

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025