loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

jaan. . 20, 2025 14:31

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

The FRP (Fiberglass Reinforced Plastic) vessel market has been burgeoning with innovations, driven by the increased demand across various industries, including chemical, food processing, and water treatment. Understanding the pricing dynamics for these vessels can be a complex but rewarding endeavor for businesses looking to invest in durable and corrosion-resistant containers. Pricing is influenced by several factors, such as material quality, design specifications, manufacturing techniques, and supplier expertise.

The reputation and expertise of the supplier add another layer to the pricing structure. Established manufacturers with a track record of delivering quality FRP vessels can command higher prices, reflecting the assurance of superior technology and adherence to rigorous quality standards. Collaborating with reputable suppliers not only provides customers with reliable products but also access to technical support, installation services, and after-sales assistance, underscoring the value-added by paying a premium. Ensuring the credibility of your product source is vital. Verifying the company's authenticity through customer reviews and third-party evaluations adds a layer of security, bolstering the trustworthiness of your purchase decision. Engaging with suppliers who exhibit transparency in their delivery timelines, production capabilities, and compliance with international manufacturing standards can significantly influence customer satisfaction and repeat business. The evolving demand dynamics for FRP vessels necessitates a cautious approach toward procurement. Understanding the interplay between product features and price helps businesses make informed decisions that balance budget constraints with the need for robust, long-lasting performance. Trust remains a critical currency in such high-stake investments, where due diligence in selecting experienced manufacturers and suppliers can determine the success of any industrial operation relying on FRP technology. Engagement in industry forums, participation in workshops, and consultations with experts can further hone an understanding of market trends and technological advancements, offering businesses a competitive edge. Leveraging such knowledge in procurement also extends the lifespan of an FRP vessel portfolio, ensuring compatibility with future industry developments while maintaining operational efficiency. In conclusion, the price of an FRP vessel encompasses more than its immediate market cost. It is a reflection of material quality, engineering prowess, manufacturing sophistication, and supplier reliability. Investing in FRP vessels requires a strategic consideration of these elements to ensure both cost-effectiveness and durability, ultimately leading businesses towards optimized operations and sustained growth.

The reputation and expertise of the supplier add another layer to the pricing structure. Established manufacturers with a track record of delivering quality FRP vessels can command higher prices, reflecting the assurance of superior technology and adherence to rigorous quality standards. Collaborating with reputable suppliers not only provides customers with reliable products but also access to technical support, installation services, and after-sales assistance, underscoring the value-added by paying a premium. Ensuring the credibility of your product source is vital. Verifying the company's authenticity through customer reviews and third-party evaluations adds a layer of security, bolstering the trustworthiness of your purchase decision. Engaging with suppliers who exhibit transparency in their delivery timelines, production capabilities, and compliance with international manufacturing standards can significantly influence customer satisfaction and repeat business. The evolving demand dynamics for FRP vessels necessitates a cautious approach toward procurement. Understanding the interplay between product features and price helps businesses make informed decisions that balance budget constraints with the need for robust, long-lasting performance. Trust remains a critical currency in such high-stake investments, where due diligence in selecting experienced manufacturers and suppliers can determine the success of any industrial operation relying on FRP technology. Engagement in industry forums, participation in workshops, and consultations with experts can further hone an understanding of market trends and technological advancements, offering businesses a competitive edge. Leveraging such knowledge in procurement also extends the lifespan of an FRP vessel portfolio, ensuring compatibility with future industry developments while maintaining operational efficiency. In conclusion, the price of an FRP vessel encompasses more than its immediate market cost. It is a reflection of material quality, engineering prowess, manufacturing sophistication, and supplier reliability. Investing in FRP vessels requires a strategic consideration of these elements to ensure both cost-effectiveness and durability, ultimately leading businesses towards optimized operations and sustained growth.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

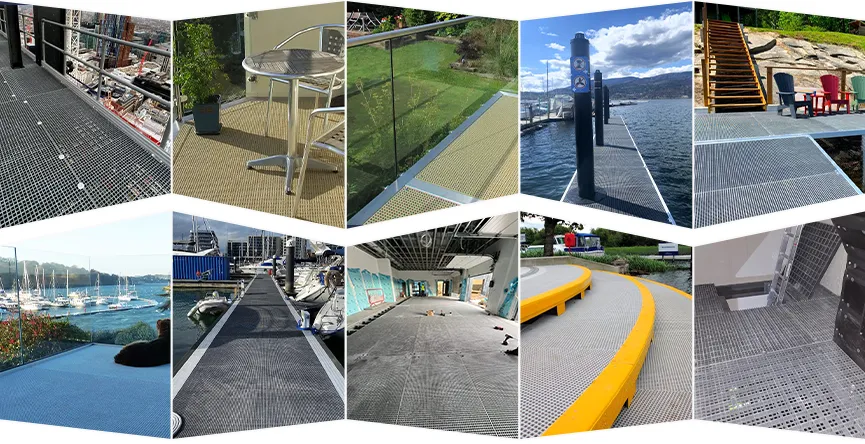

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025