loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

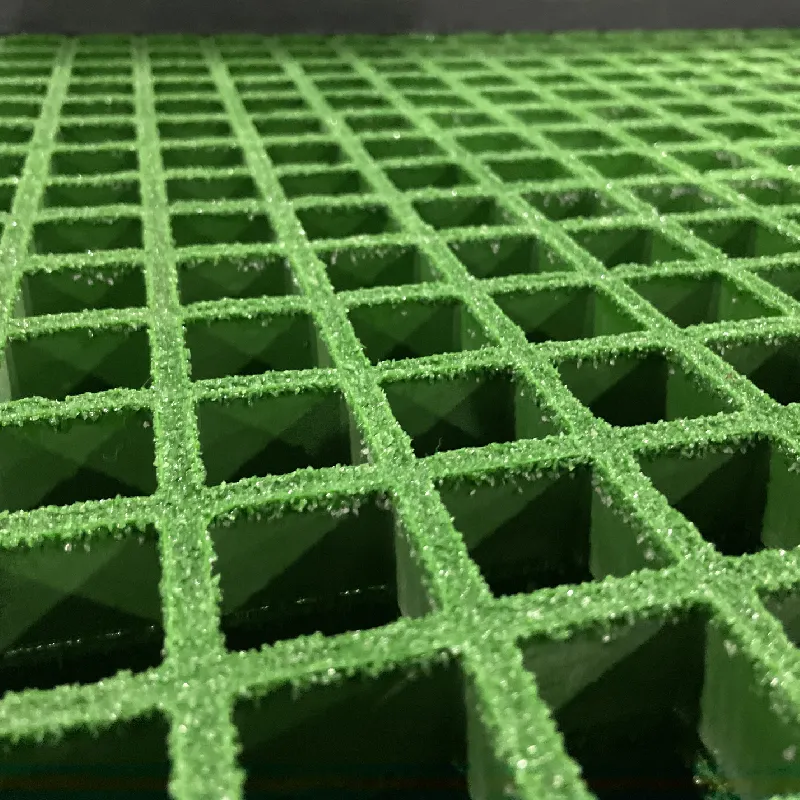

frp grill

Exploring the Benefits of FRP Grills in Modern Infrastructure

In the realm of modern construction and infrastructure, the materials chosen for various applications have a significant impact on performance, durability, and maintenance. Among these materials, Fiber Reinforced Polymer (FRP) has emerged as a game changer, particularly in the production of grills used in walkways, platforms, and industrial applications. FRP grills have gained recognition for their unique properties and advantages over traditional materials like steel and wood.

One of the standout features of FRP grills is their exceptional strength-to-weight ratio. Composed of a matrix of polymer resin and reinforcing fibers, typically glass or carbon, these grills are remarkably strong yet lightweight. This allows for easier installation and handling, reducing labor costs and improving efficiency on job sites. The lightweight nature of FRP also diminishes the structural load on foundations and support structures, enabling designs that are both innovative and sustainable.

Another significant advantage of FRP is its resistance to corrosion. Traditional materials like steel are susceptible to rust and decay, especially in environments exposed to moisture or chemicals. In contrast, FRP grills are immune to such degradation, allowing them to maintain structural integrity and appearance over time. This characteristic is particularly beneficial in harsh environments, such as wastewater treatment plants, chemical processing facilities, and coastal regions where saltwater exposure is common.

Maintenance is a crucial factor in long-term operational costs, and FRP grills shine in this regard. Unlike wooden grills that can splinter, rot, and require regular staining or painting, FRP grills are virtually maintenance-free. Their smooth surfaces are easy to clean, and they do not harbor bacteria or mold, making them ideal for environments requiring high hygiene standards, such as food processing facilities and healthcare settings.

frp grill

The versatility of FRP grills cannot be overlooked, as they can be manufactured in various shapes, sizes, and colors to suit specific project requirements. This adaptability allows designers and architects to create aesthetically pleasing structures without compromising on performance. Businesses can also customize FRP grills to meet specific safety standards, including slip resistance, which is critical in industrial applications.

Fire resistance is another important attribute of FRP materials. Many FRP products are designed to be flame retardant, making them suitable for use in locations with stringent fire safety regulations. This feature provides an added layer of security for structures where fire hazards are a concern, further enhancing the appeal of FRP grills in commercial and industrial applications.

Moreover, the environmental impact of using FRP materials is a topic of growing importance. FRP can be manufactured from recycled materials, reducing waste and promoting sustainability in construction practices. Additionally, since FRP grills have a longer lifespan compared to their traditional counterparts, they contribute to reduced material consumption over time.

In conclusion, FRP grills represent a superior alternative to traditional materials used in various construction and industrial applications. Their combination of strength, lightweight composition, corrosion resistance, low maintenance requirements, and customization options make them an ideal choice for modern infrastructure projects. As industries continue to prioritize durability and sustainability, FRP grills are set to play an increasingly pivotal role in the future of construction.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025