loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor grating price

Understanding Floor Grating Prices A Comprehensive Guide

Floor grating is a vital component in many industrial and commercial spaces, providing both safety and functionality. Used in various applications, including walkways, work platforms, and drainage systems, floor grating fulfills significant roles in ensuring structural integrity and preventing accidents. However, when it comes to incorporating floor grating into your projects, understanding the price can be complex. This article aims to break down the factors affecting floor grating prices and help you make informed decisions.

Types of Floor Grating

To grasp the pricing aspect of floor grating, it's essential to understand the different types available in the market

. The most common materials used for floor grating include1. Metal Grating Typically made from steel or aluminum, metal grating is known for its strength and longevity. It is often used in industrial applications where heavy loads are expected. The price varies significantly based on the type of metal, coating (if any), and the manufacturing process.

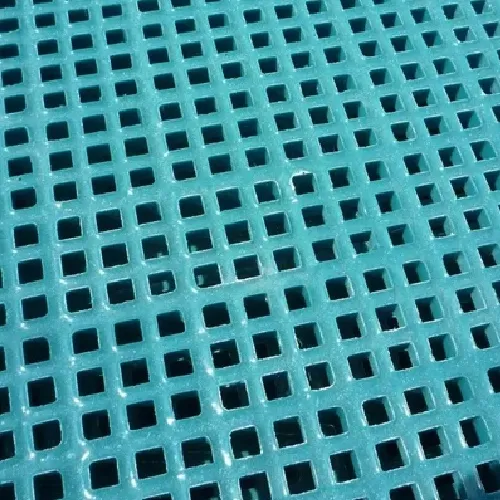

2. Fiberglass Grating This type is preferred for environments that require corrosion resistance, such as chemical plants and marine settings. Fiberglass grating can be more expensive than metal options due to its manufacturing process and material properties.

3. Plastic Grating Made from high-density polyethylene (HDPE) or other synthetic materials, plastic grating is lightweight and resistant to various chemicals. Its price point is generally lower than that of metal or fiberglass grating, making it an attractive option for some applications.

Factors Influencing Floor Grating Prices

1. Material As mentioned earlier, the material significantly impacts the price. Metal grating tends to be more expensive than plastic but may offer better durability and strength for certain applications. Fiberglass grating, while costlier, offers unique benefits like corrosion resistance, which can be a critical factor in its overall value.

2. Size and Thickness The dimensions of the grating, including its size and thickness, directly correlate with price. Larger and thicker grating requires more material and labor, thus increasing costs.

floor grating price

3. Load-Bearing Capacity Different projects may require grating that can support various loads. Higher load capacity often necessitates thicker and stronger materials, which increases the price.

4. Finish and Coatings Grating can come with different finishes or coatings, such as galvanized coatings for enhanced corrosion resistance. These additional treatments can increase the overall cost.

5. Customization Customization always comes at a premium. If your project requires specific sizes, shapes, or additional features such as slip-resistant surfaces, be prepared for higher prices.

6. Quantity Bulk orders often come with discounts, which can significantly lower the overall price per unit. If you are planning a large-scale project, it may be worth exploring this option.

7. Supplier and Location Prices can vary substantially among suppliers. Local suppliers may have different pricing structures due to shipping costs or regional demand. It’s advisable to comparison shop and seek multiple quotes before making a decision.

The Market Dynamics

The floor grating market can fluctuate based on trends in the construction and manufacturing industries. Economic conditions, raw material availability, and changes in regulations can affect prices. For instance, during periods of material shortages, prices may increase, while advances in manufacturing technology could lead to lower costs in the long term.

Conclusion

In summary, the cost of floor grating is influenced by a myriad of factors, including materials, size, load-bearing requirements, finishes, and supplier location. Understanding these elements is crucial for budgeting and planning your project effectively. Whether you are a construction manager, business owner, or contractor, taking the time to explore your options and analyze your needs can lead to significant cost savings and improved project outcomes. As with any investment, diligent research and informed purchasing decisions can yield the best value in floor grating solutions.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025