loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fibre reinforced plastic tanks and vessels

Fiber Reinforced Plastic Tanks and Vessels A Versatile Solution for Modern Industries

In recent years, the demand for advanced materials in various industries has led to the increasing adoption of fiber reinforced plastic (FRP) tanks and vessels. These innovative structures combine the lightweight properties of plastics with the strength and durability imparted by reinforcing fibers, such as glass, carbon, or aramid fibers. As industries seek sustainable and efficient solutions for storage and transport, FRP tanks have emerged as a versatile option that caters to a wide range of applications.

The Composition and Benefits of FRP

FRP is composed of a plastic matrix reinforced with fibers that provide enhanced mechanical properties. The most common type of fiber used in these applications is glass fiber, due to its excellent strength-to-weight ratio, corrosion resistance, and cost-effectiveness. Carbon fibers, while more expensive, are also used in high-performance applications that require superior strength and rigidity. This composite material is not only lightweight but also offers excellent resistance to various chemicals and environmental factors, making it ideal for industries like wastewater treatment, chemical processing, and food storage.

One of the most significant advantages of FRP tanks and vessels is their resistance to corrosion. Unlike traditional materials such as steel or concrete, which can degrade over time due to chemical attacks, FRP remains intact in harsh environments. This property drastically reduces maintenance costs and extends the lifespan of the tanks, providing a cost-effective solution for long-term storage needs.

Fiber Reinforced Plastic Tanks and Vessels A Versatile Solution for Modern Industries

FRP tanks and vessels are employed across numerous sectors, showcasing their versatility. In the water and wastewater treatment industry, they are used for storing and transporting chemicals required for processing, as well as for holding treated water. Their corrosion resistance ensures that they can handle aggressive chemicals without suffering damage.

fibre reinforced plastic tanks and vessels

In the chemical processing and oil industries, FRP vessels are preferred because they can withstand the diverse and often corrosive nature of various substances. These materials can be customized to meet specific requirements, allowing for the design of tanks that can handle pressures, temperatures, and chemicals that would challenge conventional materials.

The food and beverage sector also benefits from FRP technology. FRP tanks can be designed to meet stringent hygiene standards while effectively storing liquids like juices, dairy products, and oils. Their smooth surfaces can be easily cleaned, ensuring that food safety is maintained.

Environmental Considerations

As industries become more environmentally conscious, the choice of materials used in production processes is gaining importance. FRP tanks and vessels are not only longer-lasting and more sustainable than traditional options, but they can also be produced with recyclable materials. Furthermore, their lightweight nature means reduced energy consumption during transportation, contributing to a smaller carbon footprint.

Conclusion

In conclusion, fiber reinforced plastic tanks and vessels represent a modern solution to the challenges faced by various industries. Their robust physical and chemical properties, combined with their lightweight and corrosion-resistant nature, make them an advantageous choice for storage and transportation of fluids. As technology continues to advance, FRP is likely to play an increasingly critical role in achieving efficiency and sustainability goals across multiple sectors, paving the way for innovative applications that harness the benefits of this composite material.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

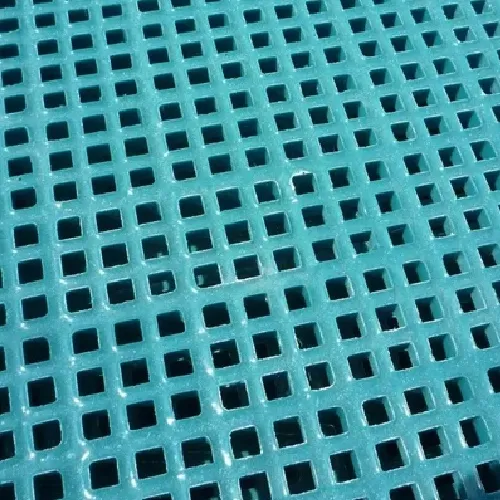

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025