loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Mechanics and Design Principles of Reinforced Concrete Using Fiber-Reinforced Polymer Bars

The Mechanics and Design of Reinforced Concrete with FRP Bars

Reinforced concrete has been a mainstay in construction for decades, providing the essential strength and durability required for various structural applications. However, the integration of Fiber Reinforced Polymer (FRP) bars into the reinforced concrete matrix has introduced innovative solutions that address many limitations associated with traditional steel reinforcement. This article will explore the mechanics and design considerations of reinforced concrete structures utilizing FRP bars.

Understanding FRP Bars

FRP bars are composite materials made from resins and high-strength fibers such as glass, carbon, or aramid. Unlike steel, FRP bars are non-corrosive, lightweight, and exhibit a high strength-to-weight ratio. These properties promote improved durability and reduced maintenance costs in structures exposed to harsh environmental conditions, such as marine or chemical environments. The use of FRP bars is particularly beneficial in applications where corrosion resistance is crucial, like in bridge structures, parking garages, and wastewater treatment facilities.

Mechanics of FRP Reinforced Concrete

The mechanics of reinforced concrete structures with FRP bars differ from those with traditional steel reinforcement. The primary difference lies in the bond characteristics and the deformation behavior of the materials. FRP bars have lower modulus of elasticity compared to steel, which affects their tension and compression responses under load. Consequently, structural engineers must consider the performance of FRP bars when evaluating the behavior of the reinforced concrete composite.

1. Stress-Strain Relationship The stress-strain response of FRP bars is generally linear up to the failure point, unlike steel, which exhibits plastic deformation. This means that engineers must carefully analyze the load-bearing capacity of a structure, as FRP does not show the yielding behavior that steel does.

2. Bonding with Concrete The bond strength between FRP bars and concrete is a critical factor in the overall performance of the structure. The bonding efficiency can be influenced by factors such as surface roughness, the presence of adhesives, and the curing process of the concrete. Proper consideration of bond properties is essential to ensure that the bars perform effectively within the concrete matrix.

3. Cracking and Deflections FRP bars can result in different cracking patterns and deflections compared to steel-reinforced concrete. Because of their lower rigidity, concrete elements reinforced with FRP may experience larger deflections under service loads, necessitating careful design to ensure serviceability limits are met.

reinforced concrete with frp bars mechanics and design

Design Considerations

When designing reinforced concrete structures with FRP bars, engineers must address a variety of factors to ensure safety, performance, and longevity

1. Material Selection The type of FRP material—be it glass, carbon, or aramid—must be chosen based on environmental exposure, load requirements, and cost considerations. Each type of FRP offers distinct advantages and disadvantages.

2. Load Calculations Accurate load calculations are fundamental for assessing the strength and serviceability of the structure. Engineers must account for both tension and compression scenarios, as well as the unique behavior of FRP bars under varying loads.

3. Durability Assessment While FRP bars offer significant advantages in corrosion resistance, their long-term performance in concrete must be thoroughly evaluated. Factors like temperature variations and UV exposure can affect the longevity of the composite materials.

4. Design Codes and Standards The design of FRP-reinforced concrete structures should adhere to established codes and standards, which may vary by region. As the use of FRP continues to grow in popularity, standardization is evolving to incorporate specific guidelines for design and application.

5. Fire Resistance Understanding the fire performance of FRP materials in structural applications is paramount. Unlike steel, which may lose strength at elevated temperatures, FRP can present unique challenges in terms of protection against fire.

Conclusion

The integration of FRP bars in reinforced concrete represents a significant advancement in construction materials and techniques. By enhancing the corrosion resistance, reducing the overall weight of structures, and potentially lowering maintenance costs, FRP bars offer a compelling alternative to traditional steel reinforcement. As the field of civil engineering continues to innovate, a deeper understanding of the mechanics and design considerations of FRP-reinforced concrete will be essential for the development of resilient and sustainable structures in the future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

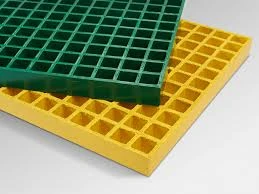

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025