loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Φεβ . 10, 2025 10:56

Back to list

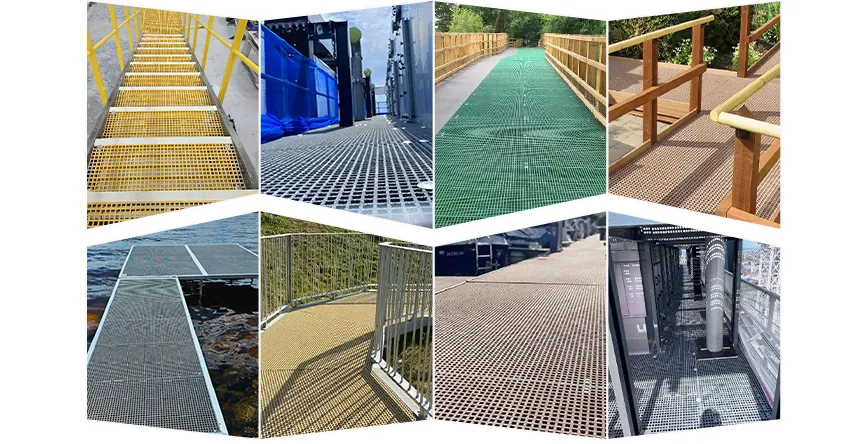

moulded fibreglass grating

Moulded fibreglass grating has rapidly become an essential component across various industries due to its exceptional properties and versatile applications. This material, known for its durability, corrosion resistance, and high strength-to-weight ratio, is redefining the standards for grating solutions in demanding environments. Let’s delve into why businesses are increasingly opting for moulded fibreglass grating and how it stands out in the competitive market.

Trust plays a pivotal role in the selection of materials for industrial applications. With a proven track record, moulded fibreglass grating has been repeatedly validated through rigorous testing and real-world application. Its performance in extreme temperatures, ranging from freezing cold to scorching heat, attests to its reliability. Unlike metal gratings that expand or contract and are susceptible to warping under extreme conditions, fibreglass maintains its structural integrity, making it a trustworthy solution for variable climates. The sustainability factor of moulded fibreglass grating cannot go unmentioned. In an increasingly eco-conscious world, industries are leaning towards sustainable and recyclable materials. Fibreglass grating not only meets these criteria but does so without compromising on quality or performance. Its long lifecycle and minimal environmental impact align well with the growing trend of sustainable industrial practices. Making a case for economic efficiency, moulded fibreglass grating tends to offer a lower total cost of ownership than traditional materials. Although the initial investment might be on par or slightly higher, the long-term savings in maintenance, replacement, and downtime present a compelling financial argument. This cost-effectiveness combined with performance benefits explains why more industries are transitioning to fibreglass solutions. Customizability is yet another advantage of moulded fibreglass grating. It can be tailored to meet specific industrial requirements, with variations in panel size, thickness, grid pattern, and resin formulation. This flexibility allows for the precise matching of grating to the intended application's demands, further enhancing its applicability and efficiency. In conclusion, moulded fibreglass grating is more than just a material choice; it's a strategic decision that supports operational efficiency and aligns with modern industrial advancements. Its composite nature offers a balanced blend of strength, safety, and sustainability that is challenging for traditional materials to match. Whether improving safety standards, reducing operational costs, or enhancing durability, moulded fibreglass grating is proving to be an invaluable asset in today’s industrial landscape. As industries continue to evolve, embracing advanced materials like moulded fibreglass grating will undoubtedly lead the way to a safer, more efficient future.

Trust plays a pivotal role in the selection of materials for industrial applications. With a proven track record, moulded fibreglass grating has been repeatedly validated through rigorous testing and real-world application. Its performance in extreme temperatures, ranging from freezing cold to scorching heat, attests to its reliability. Unlike metal gratings that expand or contract and are susceptible to warping under extreme conditions, fibreglass maintains its structural integrity, making it a trustworthy solution for variable climates. The sustainability factor of moulded fibreglass grating cannot go unmentioned. In an increasingly eco-conscious world, industries are leaning towards sustainable and recyclable materials. Fibreglass grating not only meets these criteria but does so without compromising on quality or performance. Its long lifecycle and minimal environmental impact align well with the growing trend of sustainable industrial practices. Making a case for economic efficiency, moulded fibreglass grating tends to offer a lower total cost of ownership than traditional materials. Although the initial investment might be on par or slightly higher, the long-term savings in maintenance, replacement, and downtime present a compelling financial argument. This cost-effectiveness combined with performance benefits explains why more industries are transitioning to fibreglass solutions. Customizability is yet another advantage of moulded fibreglass grating. It can be tailored to meet specific industrial requirements, with variations in panel size, thickness, grid pattern, and resin formulation. This flexibility allows for the precise matching of grating to the intended application's demands, further enhancing its applicability and efficiency. In conclusion, moulded fibreglass grating is more than just a material choice; it's a strategic decision that supports operational efficiency and aligns with modern industrial advancements. Its composite nature offers a balanced blend of strength, safety, and sustainability that is challenging for traditional materials to match. Whether improving safety standards, reducing operational costs, or enhancing durability, moulded fibreglass grating is proving to be an invaluable asset in today’s industrial landscape. As industries continue to evolve, embracing advanced materials like moulded fibreglass grating will undoubtedly lead the way to a safer, more efficient future.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025