loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Safe Mini Mesh Grating | GRP/FRP Walkways for Pedestrian Areas

Introduction to Advanced mini mesh grating for Industrial Applications

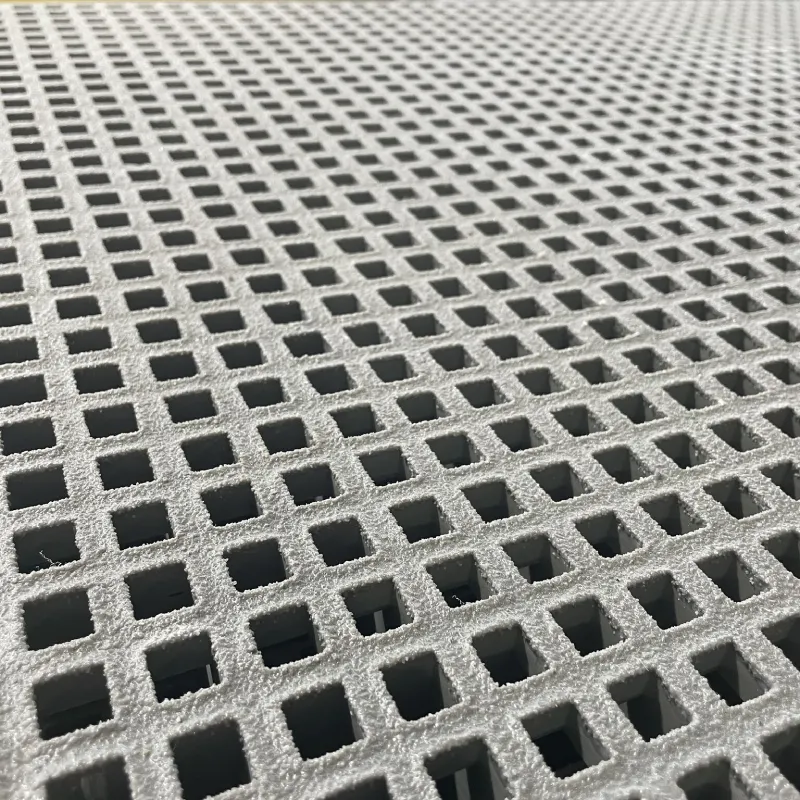

In demanding industrial environments where safety, durability, and corrosion resistance are paramount, the choice of flooring and access solutions is critical. Traditional materials often fall short, leading to high maintenance costs, safety hazards, and premature replacement. This is where advanced composite solutions, specifically mini mesh grating, emerge as a superior alternative. Designed with a smaller open mesh area, this specialized grating provides enhanced safety and support for various applications, offering a robust and long-lasting solution that significantly outperforms conventional metallic gratings.

Mini mesh grating is a high-performance, lightweight, and robust material widely adopted across an array of sectors. Its unique construction, typically made from Fiberglass Reinforced Polymer (FRP), ensures exceptional resistance to a multitude of corrosive agents, UV radiation, and extreme temperatures. The reduced mesh size is particularly advantageous for preventing small tools or objects from falling through, making it ideal for areas requiring a finer walking surface or enhanced foot traffic safety. This document delves into the technical aspects, application benefits, and strategic considerations for deploying this advanced material in your operational framework.

Industry Trends and Market Dynamics for FRP Grating Solutions

The global market for FRP grating, including specialized frp mini mesh, is experiencing substantial growth, driven by increasing industrialization, stringent safety regulations, and a growing demand for durable, low-maintenance infrastructure. According to a report by Grand View Research, the global fiberglass grating market size was valued at USD 1.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is largely attributed to the superior properties of FRP over traditional materials like steel and aluminum, particularly in corrosive environments.

Key market drivers include the burgeoning petrochemical and chemical processing industries, which require materials impervious to aggressive chemical exposure. Furthermore, the water and wastewater treatment sector, faced with continuous exposure to moisture and chemicals, increasingly opts for grp mini mesh grating due to its unparalleled corrosion resistance and extended service life. Infrastructure projects in coastal areas and regions with high humidity also contribute significantly to the demand. Emerging trends indicate a strong focus on sustainable and recyclable materials, which FRP manufacturers are addressing through advanced resin formulations and improved production processes, further solidifying its market position.

Innovations in composite manufacturing, such as enhanced resin systems offering fire retardancy and UV stability, are continually expanding the application scope of these gratings. The push for occupational safety standards also fuels the adoption of mini mesh designs, which provide a safer walking surface and prevent small items from dropping into critical machinery or processes below. This upward trend underscores the material's strategic importance in modern industrial engineering.

Detailed Manufacturing Process Flow of FRP Mini Mesh Grating

The production of high-quality grp mini mesh grating involves a meticulous manufacturing process designed to ensure structural integrity, consistent quality, and optimal performance. Unlike metallic gratings that might involve casting or forging, FRP gratings are primarily manufactured using pultrusion or molding techniques, with molded gratings being predominant for mini mesh configurations due to their isotropic strength properties and smaller mesh sizes.

Key Steps in the Molding Process:

- Material Preparation (Resin & Reinforcement): The process begins with selecting high-grade raw materials. This typically includes unsaturated polyester resin (isophthalic, orthophthalic, vinyl ester, or phenolic, depending on chemical resistance requirements) and continuous fiberglass rovings. Other additives like UV inhibitors, flame retardants, and color pigments are also incorporated to meet specific application demands.

- Mold Preparation: Precision-engineered molds, usually made from polished steel, are thoroughly cleaned and coated with a release agent to facilitate easy demolding. The mold cavity defines the final grating panel dimensions and the intricate mini mesh pattern.

- Fiberglass Layup: Continuous fiberglass rovings are strategically laid into the mold cavity, creating a layered, bi-directional reinforcement matrix. This ensures strength in both primary and secondary load-bearing directions. For mini mesh, the density of fiberglass is higher to achieve the smaller openings.

- Resin Saturation (Wet-Out): The prepared resin mixture is then poured over the fiberglass layers, thoroughly saturating the rovings. This step is critical to ensure complete encapsulation of the glass fibers, which contributes to the grating's mechanical properties and corrosion resistance.

- Curing: The filled mold is then moved to a heated oven where the resin undergoes a thermosetting polymerization process. This curing transforms the liquid resin into a solid, rigid, cross-linked polymer matrix, binding the fiberglass reinforcement into a monolithic structure. The curing temperature and time are precisely controlled to ensure optimal molecular cross-linking.

- Demolding & Post-Curing: Once cured, the grating panel is carefully demolded. In some cases, a post-curing cycle might be applied to further enhance the material's mechanical properties and chemical resistance.

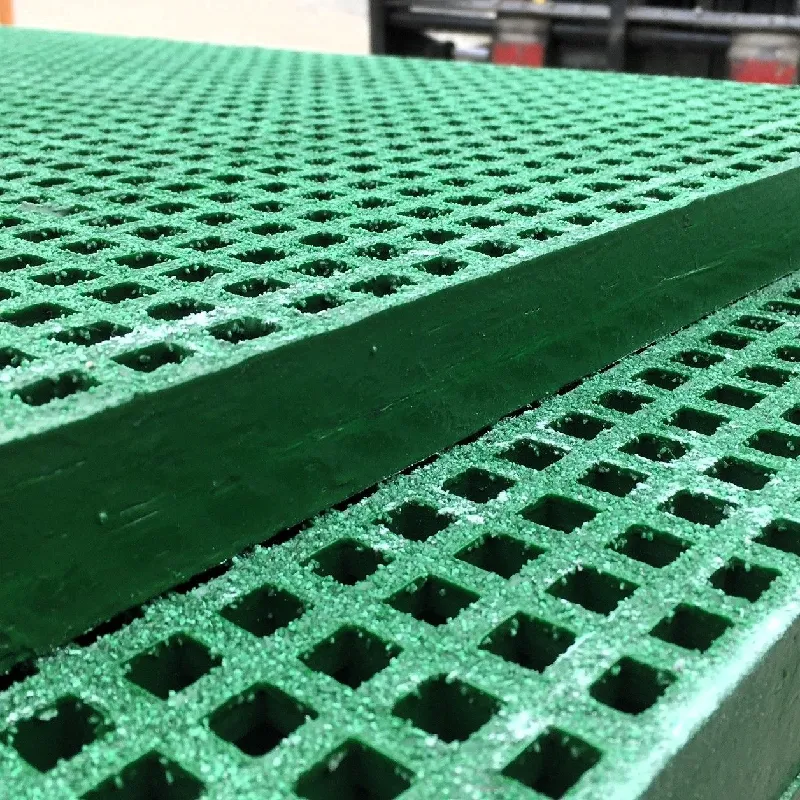

- Finishing & Surface Treatment: Edges are trimmed, and a suitable surface finish is applied. This often includes an integral grit top surface for enhanced slip resistance, an essential safety feature in industrial environments. Quality control inspections are conducted at this stage.

Quality Control & Testing Standards:

Adherence to international standards is crucial for guaranteeing product reliability. Key testing standards include:

- ASTM E-84: For flame spread and smoke development ratings, critical for fire safety.

- ASTM D-638: Tensile properties of plastics.

- ASTM D-790: Flexural properties of unreinforced and reinforced plastics and electrical insulating materials.

- ASTM D-695: Compressive properties of rigid plastics.

- ISO 9001: Quality Management System certification for the manufacturing facility.

- EN ISO 14122-3: Permanent means of access to machinery - Grating, stair treads and handrails.

The service life of a well-manufactured mini mesh grating can exceed 20-30 years in many demanding industrial applications, significantly longer than many traditional materials, especially in corrosive environments. This longevity translates into reduced lifecycle costs and minimized operational downtime for maintenance and replacement.

Technical Specifications and Parameters of FRP Mini Mesh Grating

Understanding the precise technical specifications of frp mini mesh is crucial for engineers and procurement specialists to ensure the selection of the correct product for specific operational demands. These gratings are characterized by their material composition, structural dimensions, mechanical properties, and environmental resistance profiles. The 'mini mesh' designation typically refers to an open area significantly smaller than standard square or rectangular mesh FRP gratings, often with openings around 19x19mm or smaller, offering enhanced safety and comfort underfoot.

General Product Specification Table: Smaller Open Mesh Area FRP Mini Mesh Grating

| Parameter | Typical Value/Description | Test Standard |

|---|---|---|

| Material Composition | Isophthalic Polyester Resin (Standard), Vinyl Ester (High Corrosion), Phenolic (Fire Retardant), Continuous Fiberglass Rovings (E-Glass) | Internal QA, Supplier COA |

| Mesh Size (Approx.) | 19x19mm (3/4" x 3/4") to 13x13mm (1/2" x 1/2") or smaller, often 19x19mm center-to-center for 7x7mm openings | Visual, Dimensional Gauge |

| Panel Thickness | 25mm (1"), 30mm (1.18"), 38mm (1.5") | Dimensional Gauge |

| Standard Panel Sizes | 1220x3660mm (4'x12'), 990x3000mm (3.25'x9.84'), Custom Sizes Available | Dimensional Gauge |

| Ult. Flexural Strength (Min.) | 250-300 MPa (36-43 ksi) | ASTM D-790 |

| Ult. Compressive Strength (Min.) | 150-200 MPa (22-29 ksi) | ASTM D-695 |

| Bar Density | Approx. 2000 kg/m³ (125 lb/ft³) | ASTM D-792 |

| Coefficient of Thermal Expansion | (7-9) x 10⁻⁶ mm/mm/°C (similar to steel, aiding dimensional stability) | ASTM D-696 |

| Flame Spread Index (FSI) | ≤ 25 (Class 1, for fire retardant versions) | ASTM E-84 |

| Operating Temperature Range | -50°C to +100°C (-58°F to +212°F) for Isophthalic | Manufacturer Spec |

| Surface Finish | Meniscus (Concave), Gritted (Anti-slip), Smooth (Less common for walking surfaces) | Visual |

| Weight (38mm thick) | Approx. 19-22 kg/m² (3.9-4.5 lb/ft²) - significantly lighter than steel | Calculated/Weighed |

These parameters demonstrate the robust engineering behind mini mesh grating. The selection of resin system (e.g., Isophthalic, Vinyl Ester, Phenolic) is critical and depends on the specific chemical resistance and fire retardancy required by the application. Vinyl ester resins offer superior resistance to a broader range of corrosive chemicals, while phenolic resins are specified for applications requiring exceptional fire performance, such as oil & gas platforms and underground mining. The specific bar configuration and depth define the load-bearing capacity and deflection characteristics, which must be carefully calculated based on anticipated loads and span requirements.

Key Technical Advantages of FRP Mini Mesh Grating

The adoption of grp mini mesh grating is driven by a compelling suite of technical advantages that address critical industrial challenges, offering both operational efficiency and enhanced safety. These benefits are particularly pronounced when compared to traditional metallic gratings.

- Superior Corrosion Resistance: Unlike steel, FRP does not rust or corrode when exposed to harsh chemicals, acids, alkalis, salts, and moisture. This property ensures a significantly longer service life in challenging environments such as chemical plants, wastewater treatment facilities, and marine installations, eliminating the need for frequent painting or protective coatings.

- Enhanced Safety (Slip Resistance & Smaller Openings): The integral gritted surface provides exceptional bi-directional slip resistance, even in wet or oily conditions, reducing the risk of slips and falls. The smaller mesh openings of frp mini mesh prevent small tools, nuts, bolts, or other debris from falling through, protecting equipment below and enhancing worker safety by preventing foot and finger entrapment. This also allows for the use of high heels or carts with small wheels without obstruction.

- Lightweight Construction: FRP grating is approximately one-third the weight of steel grating. This significantly reduces installation costs and effort, often eliminating the need for heavy lifting equipment. It also lowers the structural load on support structures, potentially allowing for more economical designs in new constructions or easier retrofits in existing facilities.

- Non-Conductive Properties: Being electrically and thermally non-conductive, FRP grating is ideal for applications where electrical safety is paramount. It provides a safe working platform around live electrical equipment and does not conduct heat, making it comfortable to touch in extreme temperatures.

- Low Maintenance & Extended Service Life: The inherent durability and corrosion resistance of FRP translate into minimal maintenance requirements. There's no need for sandblasting, scraping, or repainting. This drastically reduces operational expenditures over the lifespan of the installation, offering a lower total cost of ownership (TCO) compared to metallic alternatives.

- Impact Resistance: FRP has excellent energy absorption properties, meaning it can withstand impacts and heavy loads without permanent deformation, unlike metal that might dent or bend. This resilience contributes to its long-term durability.

- UV Resistance & Aesthetic Appeal: Incorporating UV inhibitors during manufacturing ensures long-term color stability and prevents degradation from sunlight exposure. Available in various colors, FRP grating can also contribute to visual aesthetics and safety zoning within a facility.

These advantages collectively position mini mesh grating as a superior material choice for a wide range of demanding industrial applications where reliability, safety, and cost-effectiveness are critical determinants of success.

Application Scenarios and Target Industries

The versatility and robust performance characteristics of mini mesh grating make it an indispensable material across a diverse range of industries. Its unique combination of corrosion resistance, strength-to-weight ratio, and safety features addresses specific challenges in critical operational areas.

Key Target Industries and Applications:

- Petrochemical and Chemical Processing: In areas exposed to acids, caustics, and other aggressive chemicals, grp mini mesh grating is ideal for platforms, walkways, trench covers, and sumps. Its non-corrosive nature ensures long-term integrity, preventing structural failures and costly replacements common with metallic options. For instance, in a chlor-alkali plant, steel gratings would rapidly degrade, whereas vinyl ester mini mesh maintains its structural integrity for decades.

- Water and Wastewater Treatment Plants: These environments are constantly wet and often expose materials to chlorine, sulfides, and other corrosive agents. FRP mini mesh is perfect for filter media support, access platforms, clarifier walkways, and manhole covers, offering anti-slip properties and excellent chemical resistance. Its lightweight nature also simplifies installation over existing basins.

- Marine and Offshore Platforms: Saltwater, humidity, and constant exposure to the elements make marine environments highly corrosive. FRP mini mesh is used for boat decks, dock walkways, offshore rig platforms, and gangways. Its non-conductive properties are also beneficial near electrical systems on vessels.

- Food and Beverage Processing: Hygiene and cleanliness are paramount. FRP grating can be specified with food-grade resins and is easy to clean, resisting bacteria growth. Its non-corrosive nature prevents rust contamination, making it suitable for wash-down areas, processing floors, and bottling plants. The small mesh prevents small dropped items from falling into food production lines.

- Pharmaceutical and Laboratory Facilities: Controlled environments benefit from FRP's inertness and resistance to various laboratory chemicals. It serves as safe flooring in cleanrooms, access platforms in research labs, and trench covers for utility lines, ensuring a contamination-free and safe working area.

- Mining and Mineral Processing: Despite the harsh, abrasive conditions, FRP mini mesh offers solutions where corrosion from acidic mine waters or chemical reagents is an issue. Its lighter weight is also an advantage in remote locations, simplifying transport and installation. For example, specific phenolic resins can be used for gratings in underground mines where fire resistance is a strict requirement.

- Electrical Utilities and Telecommunications: As an electrical insulator, FRP mini mesh is crucial for safety around high-voltage equipment, substations, and cable trenches, protecting personnel from electrical hazards.

- Manufacturing and General Industrial: Used for walkways, mezzanines, access platforms, and around machinery where oil, grease, or chemicals might be present, requiring both slip resistance and chemical inertness. The smaller openings prevent tools or fasteners from falling into operating machinery.

The strategic deployment of mini mesh grating in these sectors leads to significant advantages such as energy saving through reduced maintenance cycles, enhanced corrosion resistance, and a safer working environment, ultimately contributing to operational longevity and cost efficiency.

Customized Solutions for FRP Mini Mesh Grating

One of the significant advantages of working with advanced composite manufacturers is the capability to provide highly customized grp mini mesh grating solutions. This flexibility ensures that the grating perfectly integrates with specific project requirements, optimizing both performance and cost-effectiveness. Customization extends beyond standard panel sizes and includes resin systems, color, surface finishes, and fabrication services.

Areas of Customization:

- Resin Systems: Depending on the chemical environment, exposure to UV light, and fire performance requirements, the resin matrix can be tailored. Options include Isophthalic Polyester for general industrial use, Vinyl Ester for aggressive chemical resistance, and Phenolic for superior fire retardancy and low smoke emission.

- Panel Dimensions and Cut-outs: While standard panel sizes are available, custom cutting and fabrication services allow for precise fitting around pipes, columns, and irregular shapes, minimizing waste and installation time on-site.

- Color Options: Grating can be manufactured in a wide range of colors (e.g., yellow, grey, green, red) to match corporate branding, comply with safety coding standards (e.g., yellow for caution), or improve aesthetic integration with the facility design. Pigments are infused into the resin for long-lasting color.

- Surface Finishes: Although gritted surfaces are standard for anti-slip properties, other options like smooth, concave (meniscus), or checkered plate top can be provided based on specific requirements, such as ease of cleaning or aesthetic preference in certain areas.

- Load-Bearing Capacity & Deflection: The thickness and bar configuration can be engineered to meet specific load requirements and deflection limits for platforms, walkways, and heavy-duty applications, ensuring optimal structural integrity.

- Special Additives: Specific additives can be incorporated into the resin for enhanced UV protection, improved fire resistance, or static dissipative properties for hazardous areas.

Engaging with a manufacturer that possesses strong engineering and fabrication capabilities ensures that the custom frp mini mesh solution is not only fit-for-purpose but also optimized for performance and lifespan, aligning perfectly with project specifications and long-term operational goals.

Vendor Comparison and Selection Criteria

Selecting the right vendor for mini mesh grating is a critical decision that impacts project success, safety, and long-term cost of ownership. It goes beyond mere price comparison and involves a thorough evaluation of several key factors to ensure a reliable partnership and high-quality product delivery.

Key Vendor Comparison Factors:

- Product Quality & Certifications: Verify that the vendor's products meet international standards (e.g., ISO 9001 for quality management, ASTM, EN). Request third-party test reports for mechanical properties, fire ratings (ASTM E-84), and chemical resistance.

- Manufacturing Expertise & Technology: Assess the manufacturer's experience in FRP composite production, specifically for mini mesh grating. Look for advanced manufacturing processes, quality control procedures, and R&D capabilities.

- Customization Capabilities: A reputable vendor should offer comprehensive customization options, including different resin systems, colors, panel sizes, and fabrication services, backed by strong engineering support.

- Technical Support & Engineering Services: Evaluate the vendor's ability to provide pre-sales consultation, engineering calculations (load tables, deflection analysis), and post-sales support. A strong technical team can help optimize designs and troubleshoot challenges.

- Lead Times & Logistics: Understand the typical lead times for standard and custom orders. Assess their logistical capabilities for timely and efficient delivery, especially for large-scale projects.

- Warranty & After-Sales Service: Inquire about product warranties and the scope of after-sales support, including installation guidance, maintenance advice, and replacement policies.

- References & Case Studies: Request references from previous clients in similar industries or review documented case studies to gauge their track record and customer satisfaction.

- Cost-Effectiveness (Total Cost of Ownership): While initial price is a factor, focus on the total cost of ownership, considering the product's lifespan, maintenance requirements, and potential for reduced operational downtime.

Sample Product Comparison: FRP Mini Mesh vs. Galvanized Steel Grating (38mm Depth)

| Feature | FRP Mini Mesh Grating (Isophthalic) | Galvanized Steel Grating |

|---|---|---|

| Corrosion Resistance | Excellent (acids, alkalis, salts, moisture) | Good, but zinc coating degrades over time, especially in chemical environments. Rusts if coating compromised. |

| Weight (approx. kg/m²) | ~20 kg/m² | ~60 kg/m² (3x heavier) |

| Electrical Conductivity | Non-conductive (safe for electrical areas) | Electrically conductive (requires grounding) |

| Thermal Conductivity | Low (thermal insulator) | High (conducts heat readily) |

| Impact Resistance | High (deflects and recovers without permanent deformation) | Moderate (can dent, bend under heavy impact) |

| Slip Resistance | Excellent (integral grit surface standard) | Moderate (can be slippery when wet/oily, serrations improve but less than grit) |

| Maintenance | Very low (no painting, no rust removal) | Moderate to high (periodic cleaning, recoating if rust appears) |

| Installation | Easy (lightweight, simple cutting) | More difficult (heavy, requires specialized cutting/welding) |

| Service Life | 20-30+ years in appropriate environments | 10-20 years, highly dependent on environment and coating integrity |

| Total Cost of Ownership | Lower (higher initial cost, but significantly lower long-term maintenance and replacement) | Higher (lower initial cost, but higher long-term maintenance, replacement, and safety costs) |

This comparison highlights the compelling long-term value proposition of grp mini mesh grating, particularly when factors beyond initial purchase price are considered.

Real-World Application Case Studies

The practical deployment of mini mesh grating across various industrial settings provides compelling evidence of its transformative benefits. These case studies underscore the material's ability to address complex challenges, enhance safety, and deliver significant long-term value.

Case Study 1: Chemical Plant Walkways & Platforms

A major chemical manufacturing facility in the Gulf Coast region faced persistent issues with steel walkways and platforms corroding rapidly due to exposure to hydrochloric acid fumes and caustic spills. Regular maintenance involved costly sandblasting and recoating every 2-3 years, leading to significant downtime and safety concerns. The plant opted to replace all metallic grating with 38mm thick Vinyl Ester frp mini mesh grating. The smaller mesh provided an additional layer of safety, preventing dropped tools from entering sensitive equipment areas below. Post-installation, the grating has shown no signs of corrosion after 7 years of continuous exposure, drastically reducing maintenance costs by an estimated 70% annually and enhancing worker safety by providing a consistently slip-resistant surface. The lightweight nature of FRP also simplified installation in overhead areas, reducing crane usage and labor hours.

Case Study 2: Wastewater Treatment Plant Filter Media Support

A large municipal wastewater treatment plant needed to upgrade its filtration system, requiring robust, non-corrosive support for filter media in aerated basins. The constant immersion in chemically treated water and the presence of hydrogen sulfide made traditional materials unsuitable. Standard FRP grating had openings too large for some fine filter media. The solution involved custom-fabricated 25mm thick Isophthalic grp mini mesh grating panels. The small openings effectively supported the granular media while allowing efficient water flow. The corrosion resistance of the FRP ensured the longevity of the support structure, eliminating the need for periodic replacement that had plagued previous systems. The plant reported zero failures related to corrosion or structural integrity of the grating over a 10-year period, contributing to uninterrupted operational efficiency and reduced media loss.

Case Study 3: Food Processing Facility Wash-Down Area

A food processing facility encountered challenges in its high-hygiene wash-down areas. Stainless steel gratings, while durable, were prone to becoming slippery when wet and were heavy to lift for cleaning. The client sought a lightweight, anti-slip, and corrosion-resistant alternative. They implemented 30mm thick Isophthalic mini mesh grating with an enhanced gritted surface for new and replacement floor sections. The smaller mesh size prevented small caps or labels from falling into drainage, maintaining a cleaner environment. The lightweight panels allowed for easy removal by a single person for thorough cleaning and inspection, significantly improving hygiene standards and reducing injury risks during manual handling. The non-corrosive nature also eliminated the risk of rust contamination in a sensitive food production area, contributing to HACCP compliance.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty, and Support

Establishing trust with B2B clients requires transparent communication regarding product capabilities, logistical processes, and post-purchase support. This section addresses common inquiries and outlines commitments to ensure confidence in our mini mesh grating solutions.

Frequently Asked Questions (FAQ):

- Q1: What makes FRP mini mesh grating safer than standard FRP grating?

- A1: The primary safety advantage of mini mesh grating is its significantly smaller open mesh area. This design prevents small objects, tools, nuts, or bolts from falling through, protecting machinery or processes below. It also provides a more comfortable walking surface, preventing high heels or small-wheeled carts from getting stuck, reducing trip hazards.

- Q2: Can FRP mini mesh grating be used in highly corrosive chemical environments?

- A2: Absolutely. By selecting the appropriate resin system, such as Vinyl Ester, grp mini mesh grating offers exceptional resistance to a vast array of acids, alkalis, and solvents. It is critical to specify the exact chemical exposure conditions so our engineers can recommend the optimal resin formulation.

- Q3: Is the grating genuinely slip-resistant, especially in wet conditions?

- A3: Yes, our frp mini mesh grating is typically manufactured with an integral gritted top surface, providing superior bi-directional slip resistance. This grit is bonded during the molding process, ensuring long-lasting performance even in constantly wet, oily, or icy conditions, meeting relevant anti-slip standards.

- Q4: What is the typical lead time for ordering custom mini mesh grating?

- A4: Lead times can vary based on order size, customization requirements, and current production schedules. For standard panels, lead times are typically 2-4 weeks. For highly customized or large-volume orders, lead times might extend to 6-8 weeks. We recommend contacting our sales team for precise lead time estimates based on your specific project needs. Expedited options may be available.

Lead Time & Fulfillment:

We prioritize efficient order fulfillment to meet project timelines. Our standard lead time for stock mini mesh grating panels is typically 2-4 weeks from order confirmation to dispatch. For custom sizes, resin systems, or large project volumes, lead times are typically between 6-8 weeks. We maintain robust inventory management and a streamlined manufacturing process to ensure consistent on-time delivery. Detailed shipping and logistics information will be provided at the time of order confirmation, including tracking and estimated arrival dates.

Warranty Commitments:

We stand behind the quality and durability of our products. Our mini mesh grating comes with a standard 5-year limited warranty against manufacturing defects and material degradation under normal operating conditions and specified chemical exposures. Specific warranty terms may vary based on product type and application; full details are available upon request and provided with every product order.

Customer Support & Authoritative References:

Our commitment extends beyond product delivery. We offer comprehensive pre-sales consultation and post-sales support, including:

- Technical Assistance: Our team of experienced engineers provides expert advice on product selection, load calculations, chemical compatibility, and installation best practices.

- Fabrication & Installation Guides: Detailed instructions and best practices for cutting, fitting, and securing grating panels.

- Certifications: Our manufacturing facilities are ISO 9001:2015 certified, ensuring consistent quality management. Our products are regularly tested to meet or exceed relevant international standards, including ASTM (American Society for Testing and Materials) for mechanical properties and fire ratings, and EN ISO (European Norms/International Organization for Standardization) standards for safety and performance in industrial applications. We also have successful long-term partnerships with leading companies in the petrochemical, wastewater, and marine sectors, which serve as strong testimonials to our product reliability and service excellence.

For any inquiries or support, please contact our dedicated customer service team, available via phone or email during business hours. We are committed to ensuring your project's success and your complete satisfaction.

Conclusion

The strategic integration of mini mesh grating into industrial infrastructure represents a forward-thinking approach to enhancing safety, maximizing operational longevity, and significantly reducing long-term maintenance costs. Its unparalleled resistance to corrosion, combined with high strength-to-weight ratio, superior slip resistance, and electrical non-conductivity, positions it as an indispensable material in a multitude of challenging environments—from petrochemical processing and wastewater treatment to marine installations and food production facilities.

By understanding the detailed manufacturing processes, technical specifications, and broad application potential, B2B decision-makers can make informed choices that contribute to safer workplaces, more resilient infrastructure, and a lower total cost of ownership. The ability to customize these solutions further ensures that specific project requirements are not just met, but optimized, leading to engineered excellence that stands the test of time. Embracing advanced composite solutions like mini mesh grating is a strategic investment in the future of industrial safety and efficiency.

Citations

- Grand View Research. (2023). Fiberglass Grating Market Size, Share & Trends Analysis Report By Resin Type, By Application, By Region, And Segment Forecasts, 2023 - 2030. Retrieved from Grand View Research.

- ASTM International. (n.d.). Standards for FRP Composites. Retrieved from ASTM International.

- ISO. (n.d.). ISO 9001 - Quality management. Retrieved from International Organization for Standardization.

- Fibreglass Reinforced Plastics (FRP) Grating – A Comprehensive Guide. (2022). Composites One. Retrieved from Composites One.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025