loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 14, 2025 12:00

Back to list

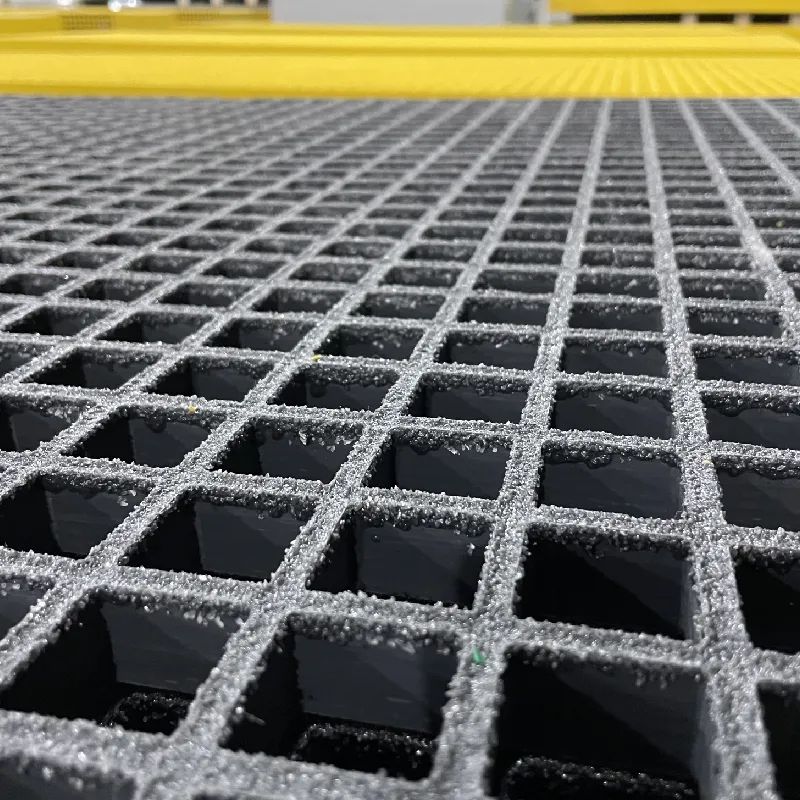

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Molded fiberglass grating is swiftly becoming a top choice for industries across the globe, predominantly due to its exceptional properties that seamlessly blend durability, safety, and versatility. This high-performance material is crafted from interwoven glass fibers encased in a resin matrix. Its uniqueness lies in the combination of immense strength and lightweight nature, catering to diverse applications, especially in corrosive environments where traditional materials falter.

Authoritativeness in the field of molded fiberglass grating is underscored by rigorous testing and certification by reputable organizations. These gratings often comply with global standards like ASTM, ANSI, and OSHA, assuring stakeholders of their performance reliability and safety credentials. Furthermore, numerous case studies from leading industrial sectors document the successful deployment of molded fiberglass grating, reinforcing confidence in its application and efficacy. Trustworthiness is key to adopting new materials in industrial projects, and molded fiberglass grating has earned this through consistent performance and customer satisfaction. The overall lifecycle of these gratings is enhanced by their formidable resistance to UV radiation and extreme temperature fluctuations, which guarantees long-lasting performance under varying environmental conditions. Clients across industries have vouched for the reliability and low total cost of ownership presented by these gratings, often citing the comprehensive warranties offered by manufacturers as a testament to their guarantee of quality. In conclusion, molded fiberglass grating presents a synergy of safety, durability, and cost-efficiency that is backed by industry expertise and authoritative endorsements. Its unique attributes align with the growing demand for sustainable, reliable, and low-maintenance materials in industrial infrastructure. As industries continue to shift towards innovative materials solutions, molded fiberglass grating stands out as a pivotal component in enhancing operational efficacy and safety, promising a broad spectrum of applications that extend far beyond conventional expectations.

Authoritativeness in the field of molded fiberglass grating is underscored by rigorous testing and certification by reputable organizations. These gratings often comply with global standards like ASTM, ANSI, and OSHA, assuring stakeholders of their performance reliability and safety credentials. Furthermore, numerous case studies from leading industrial sectors document the successful deployment of molded fiberglass grating, reinforcing confidence in its application and efficacy. Trustworthiness is key to adopting new materials in industrial projects, and molded fiberglass grating has earned this through consistent performance and customer satisfaction. The overall lifecycle of these gratings is enhanced by their formidable resistance to UV radiation and extreme temperature fluctuations, which guarantees long-lasting performance under varying environmental conditions. Clients across industries have vouched for the reliability and low total cost of ownership presented by these gratings, often citing the comprehensive warranties offered by manufacturers as a testament to their guarantee of quality. In conclusion, molded fiberglass grating presents a synergy of safety, durability, and cost-efficiency that is backed by industry expertise and authoritative endorsements. Its unique attributes align with the growing demand for sustainable, reliable, and low-maintenance materials in industrial infrastructure. As industries continue to shift towards innovative materials solutions, molded fiberglass grating stands out as a pivotal component in enhancing operational efficacy and safety, promising a broad spectrum of applications that extend far beyond conventional expectations.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025