Wird geladen...

- Nr. 9, Xingyuan South Street, Dongwaihuan Road, Kreis Zaoqiang, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Willkommen auf unserer Website!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Englisch

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

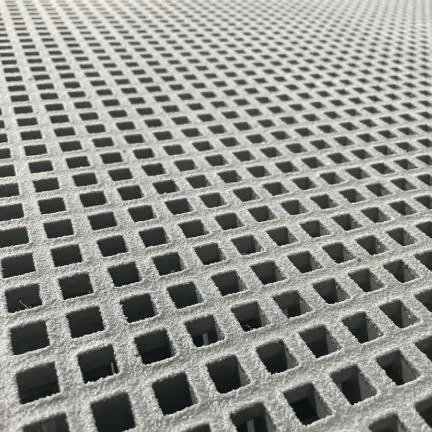

He Versatility and Strength of Mini Mesh Grating for Your Projects

When it comes to choosing the right grating material for industrial, commercial, or even residential applications, mini mesh grating has emerged as a leading solution. Whether you are looking for strength, durability, or versatility, mini mesh grating options such as GRP mini mesh grating and FRP mini mesh grating offer impressive features that meet the needs of various industries. In this article, we will explore the benefits, types, and applications of mini mesh grating, focusing on how GRP mini mesh grating and FRP mini mesh grating are transforming the way grating systems are used. By the end of this piece, you will have a comprehensive understanding of why mini mesh grating is the right choice for your next project.

What is Mini Mesh Grating and How Does it Benefit Your Project?

Mini mesh grating is a highly durable, lightweight, and versatile material designed for use in a wide range of applications. Unlike traditional metal grating, mini mesh grating is made with smaller openings, which increases its load-bearing capacity and enhances its strength. This feature makes it ideal for both pedestrian and vehicular traffic in environments where safety and durability are critical.

The primary advantage of mini mesh grating lies in its ability to provide excellent traction while maintaining a high level of safety. The smaller mesh openings prevent debris from falling through, making it especially useful for industrial environments, construction sites, and commercial spaces. Mini mesh grating also helps to reduce the risk of accidents by offering a slip-resistant surface that is particularly effective in wet or oily conditions.

Moreover, mini mesh grating offers resistance to corrosion, especially when manufactured from composite materials like GRP mini mesh grating or FRP mini mesh grating. These variants are specifically designed to withstand harsh environments such as chemical exposure, extreme temperatures, and heavy foot or vehicle traffic. The durability of mini mesh grating makes it a cost-effective choice for long-term applications.

GRP Mini Mesh Grating: The Ideal Solution for Corrosive Environments

When it comes to grating solutions for environments exposed to chemicals, moisture, and harsh conditions, GRP mini mesh grating (Glass Reinforced Plastic) is one of the best choices available. GRP mini mesh grating is made from a combination of fiberglass and resin, which makes it highly resistant to corrosion. This makes it ideal for industries such as chemical processing, wastewater treatment, food processing, and marine environments.

One of the standout features of GRP mini mesh grating is its ability to withstand aggressive chemicals and extreme weather conditions without deteriorating or losing structural integrity. Unlike metal grating, which can rust and degrade in corrosive environments, GRP mini mesh grating remains intact, providing a reliable and long-lasting solution for industrial needs. Additionally, it’s lightweight and easy to install, which reduces both time and labor costs during installation.

The non-conductive nature of GRP mini mesh grating makes it a safe choice for environments where electrical conductivity is a concern. The grating is also resistant to UV degradation, meaning that it won’t weaken or become brittle when exposed to sunlight. This makes it a reliable option for outdoor and exposed installations.

FRP Mini Mesh Grating: Strength and Durability Combined

FRP mini mesh grating (Fiber Reinforced Plastic) is another composite material designed for strength, durability, and safety. Like GRP mini mesh grating, FRP mini mesh grating is made from fiberglass reinforced with plastic resin. The main difference lies in the specific resin used, which may vary based on the application. FRP mini mesh grating is known for its exceptional load-bearing capabilities, making it suitable for a variety of industrial applications.

FRP mini mesh grating provides numerous advantages, including resistance to both chemical and physical wear and tear. It is particularly effective in environments where metal grating would typically corrode or break down. FRP mini mesh grating can handle high impact, heavy loads, and extreme temperatures without compromising on performance, making it a perfect choice for industries like mining, oil and gas, and manufacturing.

The FRP mini mesh grating is also incredibly versatile, as it can be customized in terms of color, size, and configuration to meet the specific needs of your project. This customization ensures that the grating fits seamlessly into your design while maintaining its structural integrity over time. The lightweight nature of FRP mini mesh grating makes it easier to handle during installation, reducing both effort and costs involved in setting up the grating system.

Applications of Mini Mesh Grating in Various Industries

Mini mesh grating is utilized across multiple industries due to its versatility and performance in challenging environments. Below are some key applications of GRP mini mesh grating and FRP mini mesh grating in various sectors:

Chemical Industry: The GRP mini mesh grating is perfect for environments where chemicals are handled. Due to its resistance to corrosion, it is commonly used in chemical processing plants, where the grating can withstand exposure to harsh chemicals without deteriorating.

Oil and Gas Industry: FRP mini mesh grating is widely used in the oil and gas industry because of its ability to withstand extreme temperatures, corrosive substances, and heavy mechanical loads. It’s often used in offshore platforms, refineries, and storage tanks.

Water Treatment Plants: Both GRP mini mesh grating and FRP mini mesh grating are used extensively in water treatment plants. These materials are resistant to corrosion from prolonged exposure to water and harsh chemicals, ensuring the longevity of the grating and the safety of plant workers.

Marine and Coastal Applications: The ability of GRP mini mesh grating and FRP mini mesh grating to withstand saltwater exposure makes them ideal for marine applications. They are used in docks, piers, and coastal facilities where the grating needs to resist corrosion from saltwater and UV rays.

Commercial and Residential Applications: Mini mesh grating also serves non-industrial purposes, such as in staircases, walkways, and platforms in commercial and residential buildings. The slip-resistant properties and aesthetic flexibility make it a preferred choice for both safety and design.

Why Choose Mini Mesh Grating Over Traditional Metal Grating?

While traditional metal grating has been the standard in various applications for many years, mini mesh grating made from composites like GRP mini mesh grating and FRP mini mesh grating offers distinct advantages that make it a superior choice. Some of the reasons to choose mini mesh grating over metal options include:

Corrosion Resistance: Unlike metal grating, which can rust and corrode over time, mini mesh grating made from GRP or FRP remains corrosion-resistant, ensuring a longer lifespan, especially in harsh environments.

Lightweight and Easier to Install: Mini mesh grating is significantly lighter than traditional metal grating, making it easier and more cost-effective to transport and install.

Slip Resistance: The slip-resistant surface of mini mesh grating makes it ideal for environments where safety is a top priority. This feature is particularly beneficial in wet or oily areas, reducing the risk of accidents.

Geringer Wartungsaufwand: Mini mesh grating requires less maintenance compared to metal alternatives, making it a cost-effective long-term solution. It won’t need to be treated for rust or corrosion, saving you money on upkeep.

Customizability: Both GRP mini mesh grating and FRP mini mesh grating can be customized to fit specific design needs, whether in terms of size, color, or mesh configuration, which is not always possible with metal grating.

GRP Mini Mesh Grating FAQs

What is the difference between GRP and FRP mini mesh grating?

GRP (Glass Reinforced Plastic) and FRP (Fiber Reinforced Plastic) mini mesh grating both offer excellent durability and resistance to corrosion. The key difference lies in the type of resin used. GRP uses a resin that is specifically tailored for environments exposed to moisture and chemicals, while FRP uses a resin that provides better impact resistance and high-strength applications.

Can mini mesh grating be used outdoors?

Yes, both GRP and FRP mini mesh grating can be used outdoors. These materials are resistant to UV rays, moisture, and extreme temperatures, making them perfect for outdoor applications such as walkways, platforms, and marine environments.

Is mini mesh grating easy to install?

Yes, mini mesh grating is relatively easy to install. Due to its lightweight nature, it is easy to handle and cut to the required size. However, proper installation techniques should be followed to ensure stability and safety.

How long does mini mesh grating last?

Mini mesh grating, especially when made from GRP or FRP, can last for many years, often exceeding 30 years, depending on the application and environment. These materials are resistant to corrosion and wear, ensuring a long lifespan without the need for frequent replacement.

How do I maintain mini mesh grating?

Mini mesh grating requires minimal maintenance. It should be cleaned regularly to remove debris and dirt. In environments with chemicals or heavy usage, periodic inspections are recommended to ensure its integrity, but overall, the grating is very low-maintenance compared to metal options.

In conclusion, mini mesh grating, particularly GRP mini mesh grating and FRP mini mesh grating, offers outstanding advantages in terms of durability, safety, and cost-effectiveness. Whether for industrial, commercial, or residential applications, these grating options provide long-lasting solutions that meet the demands of even the harshest environments. By choosing mini mesh grating, you ensure safety, reliability, and efficiency in your projects.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNachrichtNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNachrichtNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNachrichtNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNachrichtNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNachrichtNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNachrichtNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNachrichtNov.11,2025