loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Advantages and Applications of FRP Vessels in Modern Industry

The Rise of FRP Vessels Innovations in Marine Engineering

In recent years, the marine industry has witnessed a remarkable shift towards the utilization of Fiber Reinforced Polymer (FRP) vessels. These modern crafts, made from advanced composite materials, offer a plethora of advantages over conventional boat-building materials such as wood, steel, and aluminum. As the demand for durable, lightweight, and corrosion-resistant vessels escalates, FRP technology is taking center stage in marine engineering.

FRP is a composite material that consists of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The primary advantage of using FRP in vessel construction lies in its exceptional strength-to-weight ratio. This quality enables the design of lighter vessels without compromising structural integrity, resulting in improved fuel efficiency and enhanced speed. The reduced weight also facilitates easier handling during launching and docking, further benefiting operators.

The Rise of FRP Vessels Innovations in Marine Engineering

Moreover, the design flexibility offered by FRP allows for more innovative and creative vessel designs. Manufacturers can easily mold FRP into complex shapes, enabling the construction of vessels tailored to specific needs and applications. This adaptability is particularly beneficial in niche markets like luxury yachts, specialized fishing boats, and research vessels, where customized features can enhance functionality and aesthetics.

frp vessels

The integration of advanced technologies in FRP vessel construction has also played a pivotal role in its advancement. The infusion of computer-aided design (CAD) and simulation technologies streamlines the design process, allowing for precise analysis and optimization. Additionally, the incorporation of automated manufacturing processes, such as vacuum infusion and robotic layup, ensures consistent quality and reduces production time. These innovations make FRP vessels not only a viable alternative but often an industry standard in modern marine construction.

Despite its numerous advantages, the adoption of FRP vessels has not been without challenges. The initial cost of production remains a significant barrier for some shipbuilders and operators. FRP materials and manufacturing techniques can be more expensive compared to traditional materials, which may deter smaller companies or projects with tight budgets. Furthermore, the recycling and disposal of FRP at the end of its lifecycle presents environmental concerns, as the composite materials are not biodegradable and can contribute to waste if not managed properly.

Nevertheless, the industry is adapting, with ongoing research focusing on the development of recyclable FRP materials and better manufacturing processes that could lower costs. Many governments and organizations are now advocating for sustainable practices in marine construction, pushing for innovations that could mitigate the environmental footprint of FRP vessels.

In conclusion, the rise of FRP vessels represents a significant advancement in marine engineering, characterized by their lightweight, corrosion-resistant, and versatile nature. As the marine industry continues to evolve and seeks solutions to sustainability challenges, FRP technology is poised to play an integral role in shaping the future of vessel design and manufacturing. By overcoming the existing challenges, the potential for FRP vessels is immense, promising a new era of efficiency and eco-friendly boating. With the continued innovation and commitment from the industry, FRP vessels will undoubtedly mark a transformative chapter in the maritime landscape.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

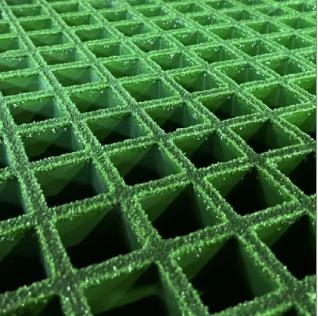

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025