loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

jan . 26, 2025 02:06

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

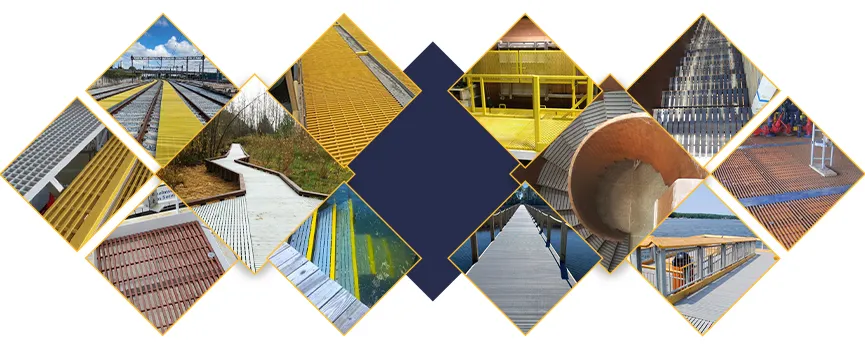

In the fast-evolving landscape of construction and industrial materials, the FRP flat bar has emerged as a groundbreaking innovation, rapidly gaining traction across various sectors. Its unique composition and unrivaled properties make it a standout choice for professionals seeking durability, flexibility, and reliability in their applications. Let's delve into the myriad benefits and applications of FRP flat bars, shedding light on why they are becoming the go-to option for experts worldwide.

Moreover, the low thermal expansion coefficient of FRP flat bars enhances their dimensional stability across varying environmental conditions. Unlike metals that may expand or contract with temperature changes, FRP maintains its shape, ensuring the integrity and safety of the structure. This feature is critical in projects exposed to extreme temperature fluctuations, where stability and reliability are paramount. Professionals in the field recognize the significance of sustainability and the growing demand for environmentally friendly materials. FRP flat bars align perfectly with these objectives. Their production process is energy-efficient, and the longevity they offer minimizes resource consumption over time. As green building certifications become increasingly important, the use of sustainable materials like FRP can contribute positively towards achieving these certifications, reinforcing their position as a material of the future. The competitive edge offered by FRP flat bars is further evidenced by a plethora of real-world applications and testimonials from leading industry experts. From corrosion-resistant handrails in coastal infrastructure projects to lightweight yet strong reinforcements in bridges and overpasses, the versatility of FRP continues to captivate and convince many sectors. With a growing library of case studies and an expanding suite of applications, the trust placed in FRP flat bars is not just an endorsement of their capabilities but a testament to the material's potential to redefine the standards of modern construction and manufacturing practices. As studies and feedback from both field applications and controlled experiments accumulate, the authority of FRP in the materials space is bound to cement itself further, encouraging widespread adoption and ushering in new possibilities for innovation and efficiency. In conclusion, the FRP flat bar is not merely a product; it is a technological advancement that addresses pressing challenges faced by industries today. By offering unmatched performance and reliability, it proves to be a smart investment for those who demand the best in both quality and sustainability. As more professionals experience firsthand the benefits of integrating FRP flat bars into their projects, it becomes increasingly evident that its role in building the future is not just assured but irresistible.

Moreover, the low thermal expansion coefficient of FRP flat bars enhances their dimensional stability across varying environmental conditions. Unlike metals that may expand or contract with temperature changes, FRP maintains its shape, ensuring the integrity and safety of the structure. This feature is critical in projects exposed to extreme temperature fluctuations, where stability and reliability are paramount. Professionals in the field recognize the significance of sustainability and the growing demand for environmentally friendly materials. FRP flat bars align perfectly with these objectives. Their production process is energy-efficient, and the longevity they offer minimizes resource consumption over time. As green building certifications become increasingly important, the use of sustainable materials like FRP can contribute positively towards achieving these certifications, reinforcing their position as a material of the future. The competitive edge offered by FRP flat bars is further evidenced by a plethora of real-world applications and testimonials from leading industry experts. From corrosion-resistant handrails in coastal infrastructure projects to lightweight yet strong reinforcements in bridges and overpasses, the versatility of FRP continues to captivate and convince many sectors. With a growing library of case studies and an expanding suite of applications, the trust placed in FRP flat bars is not just an endorsement of their capabilities but a testament to the material's potential to redefine the standards of modern construction and manufacturing practices. As studies and feedback from both field applications and controlled experiments accumulate, the authority of FRP in the materials space is bound to cement itself further, encouraging widespread adoption and ushering in new possibilities for innovation and efficiency. In conclusion, the FRP flat bar is not merely a product; it is a technological advancement that addresses pressing challenges faced by industries today. By offering unmatched performance and reliability, it proves to be a smart investment for those who demand the best in both quality and sustainability. As more professionals experience firsthand the benefits of integrating FRP flat bars into their projects, it becomes increasingly evident that its role in building the future is not just assured but irresistible.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025