loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Chw . 16, 2025 12:42

Back to list

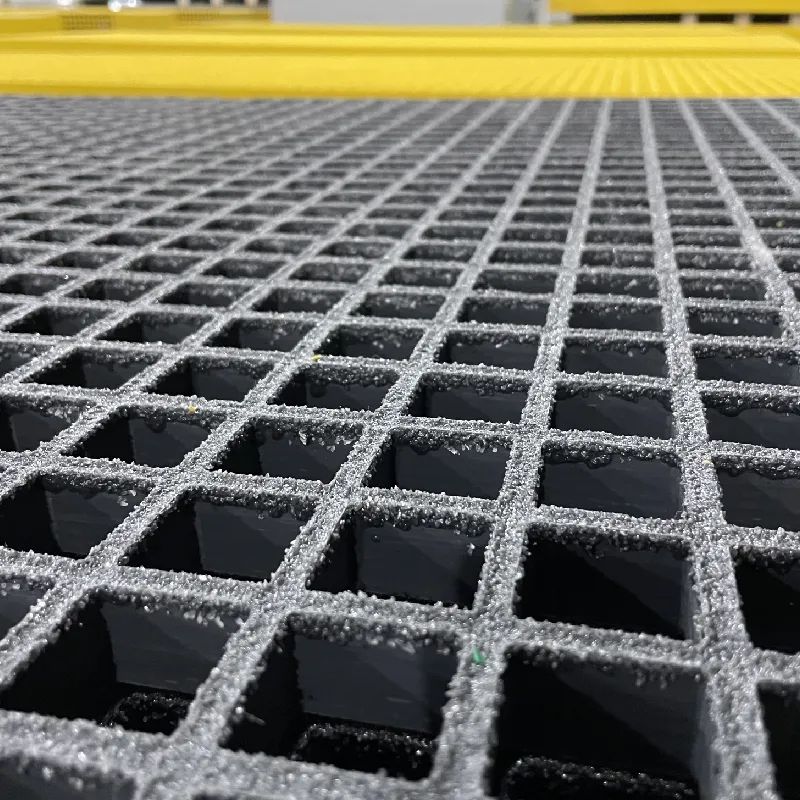

frp platform grating

FRP platform grating has gradually become the material of choice for various industries seeking durability combined with safety. As companies continue to innovate, interest in FRP (Fiberglass Reinforced Plastic) gratings has surged. This expansion is largely due to their several unmatched qualities that provide both cost-effectiveness and operational efficiency in diverse environments.

Further augmenting their appeal is the non-conductive property of FRP gratings. Unlike metal, they do not conduct electricity, thereby significantly mitigating the risk of electrical hazards. This feature makes FRP gratings an excellent choice for electrical substations, railway tracks, and other environments where electrical safety is paramount. By using FRP, industries can adhere to strict safety standards without compromising on performance. Endurance in fluctuating temperatures also highlights FRP platform gratings as a superior choice. Their resilience to extreme temperature variations endows them with the ability to function in frigid or scorching environments without warping or becoming brittle. This quality ensures operational continuity and safeguards against weather-related disruptions, making FRP gratings suitable for outdoor installations as well as in regions with severe climate conditions. As sustainability increasingly becomes a central concern, FRP gratings offer a tangible environmental advantage. They require less maintenance, have a long lifespan, and when eventually replaced, entail less environmental impact than traditional alternatives. Many manufacturers are now focusing on producing FRP materials that can be recycled, further enhancing their environmental credentials and aligning with global sustainability goals. The expertise in producing and applying FRP platform gratings has evolved, leading to a more proficient workforce adept at leveraging these materials in innovative applications. Companies offering FRP solutions often back their products with technical assistance, ensuring that clients receive guidance tailored to their unique operational challenges. This commitment to support strengthens the trust industries place in FRP gratings, confirming them as a reliable component in infrastructural development. In conclusion, FRP platform grating emerges not merely as a material but as a pivotal element for modern infrastructure demands. Its fusion of durability, adaptability, and safety makes it indispensable for industries aiming to optimize performance while conserving resources. Trusting in the expertise and proven track record of FRP specialists ensures that industries not only keep pace with technological advancements but also prioritize longevity and safety in their operations. The shift towards FRP platform grating is not a transient trend but an informed decision backed by demonstrable benefits.

Further augmenting their appeal is the non-conductive property of FRP gratings. Unlike metal, they do not conduct electricity, thereby significantly mitigating the risk of electrical hazards. This feature makes FRP gratings an excellent choice for electrical substations, railway tracks, and other environments where electrical safety is paramount. By using FRP, industries can adhere to strict safety standards without compromising on performance. Endurance in fluctuating temperatures also highlights FRP platform gratings as a superior choice. Their resilience to extreme temperature variations endows them with the ability to function in frigid or scorching environments without warping or becoming brittle. This quality ensures operational continuity and safeguards against weather-related disruptions, making FRP gratings suitable for outdoor installations as well as in regions with severe climate conditions. As sustainability increasingly becomes a central concern, FRP gratings offer a tangible environmental advantage. They require less maintenance, have a long lifespan, and when eventually replaced, entail less environmental impact than traditional alternatives. Many manufacturers are now focusing on producing FRP materials that can be recycled, further enhancing their environmental credentials and aligning with global sustainability goals. The expertise in producing and applying FRP platform gratings has evolved, leading to a more proficient workforce adept at leveraging these materials in innovative applications. Companies offering FRP solutions often back their products with technical assistance, ensuring that clients receive guidance tailored to their unique operational challenges. This commitment to support strengthens the trust industries place in FRP gratings, confirming them as a reliable component in infrastructural development. In conclusion, FRP platform grating emerges not merely as a material but as a pivotal element for modern infrastructure demands. Its fusion of durability, adaptability, and safety makes it indispensable for industries aiming to optimize performance while conserving resources. Trusting in the expertise and proven track record of FRP specialists ensures that industries not only keep pace with technological advancements but also prioritize longevity and safety in their operations. The shift towards FRP platform grating is not a transient trend but an informed decision backed by demonstrable benefits.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025