loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Úno . 02, 2025 03:29

Back to list

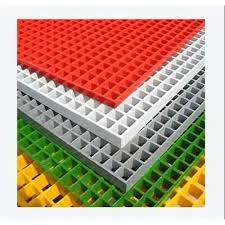

frp micro mesh grating

Fiberglass reinforced plastic (FRP) mesh grating is revolutionizing industries where performance, safety, and durability are paramount. This advanced composite material is providing solutions to traditional grating problems faced by industries such as oil & gas, wastewater management, chemical processing, and marine operations.

Trustworthiness is another critical factor where FRP mesh grating shines. Its flame-retardant properties are outstanding, meeting or exceeding numerous industry safety standards. This means that in the unfortunate event of a fire, FRP grating will contribute significantly less to the spread of flames compared to traditional materials. Additionally, its electrical non-conductivity ensures safe operation in environments where electrical hazards are a concern. This quality makes FRP mesh grating particularly suitable for electrical plants and chemical factories, where safety hazards are a significant concern. A real-world experience underscores the practical benefits of FRP mesh grating in industrial applications. A chemical processing facility facing repeated structural failures due to corrosion from acid vapors transitioned to FRP mesh grating. Not only did the switch eradicate their corrosion issues, but it also improved safety conditions and reduced maintenance downtimes. The facility’s management reported a significant increase in operational efficiency and cost savings, affirming their decision to adopt this advanced material. Furthermore, customization options with FRP mesh grating are notable. Available in various resin formulations, colors, and sizes, these gratings can be tailored to meet specific project needs. Customization ensures that every aspect of a project’s safety, aesthetic, and functional requirements is met, making FRP mesh grating a versatile choice for architects and engineers alike. In summary, FRP mesh grating is not just a superior alternative to traditional materials; it embodies modern engineering advancements tailored to meet the unique challenges of various industries. Its excellent strength-to-weight ratio, unmatched corrosion resistance, flame-retardant qualities, and customization capabilities make it an indispensable asset. Industries looking to reduce costs, enhance safety, and improve efficiency need look no further than FRP mesh grating, a proven solution that continues to pioneer new standards in industrial grating applications.

Trustworthiness is another critical factor where FRP mesh grating shines. Its flame-retardant properties are outstanding, meeting or exceeding numerous industry safety standards. This means that in the unfortunate event of a fire, FRP grating will contribute significantly less to the spread of flames compared to traditional materials. Additionally, its electrical non-conductivity ensures safe operation in environments where electrical hazards are a concern. This quality makes FRP mesh grating particularly suitable for electrical plants and chemical factories, where safety hazards are a significant concern. A real-world experience underscores the practical benefits of FRP mesh grating in industrial applications. A chemical processing facility facing repeated structural failures due to corrosion from acid vapors transitioned to FRP mesh grating. Not only did the switch eradicate their corrosion issues, but it also improved safety conditions and reduced maintenance downtimes. The facility’s management reported a significant increase in operational efficiency and cost savings, affirming their decision to adopt this advanced material. Furthermore, customization options with FRP mesh grating are notable. Available in various resin formulations, colors, and sizes, these gratings can be tailored to meet specific project needs. Customization ensures that every aspect of a project’s safety, aesthetic, and functional requirements is met, making FRP mesh grating a versatile choice for architects and engineers alike. In summary, FRP mesh grating is not just a superior alternative to traditional materials; it embodies modern engineering advancements tailored to meet the unique challenges of various industries. Its excellent strength-to-weight ratio, unmatched corrosion resistance, flame-retardant qualities, and customization capabilities make it an indispensable asset. Industries looking to reduce costs, enhance safety, and improve efficiency need look no further than FRP mesh grating, a proven solution that continues to pioneer new standards in industrial grating applications.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025