loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

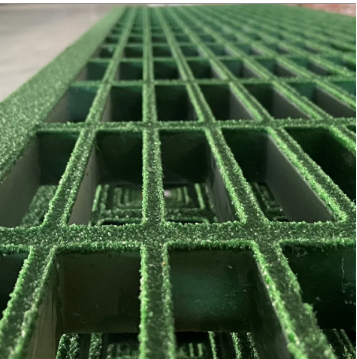

Fibreglass Grating for Industrial Walkways

Industrial walkways demand materials that balance strength, safety, and resistance to harsh conditions—and fibreglass grating emerges as the gold standard for this critical application. Unlike steel grating that rusts, wood that rots, or concrete that cracks under stress, fibreglass grating (including durable GRP mesh flooring variants) offers a unique combination of corrosion resistance, lightweight design, and low maintenance—making it ideal for factories, refineries, chemical plants, and wastewater treatment facilities. Zhaojia Composites Co., Ltd (ZJ Composites), a leader in composite materials with a focus on quality and innovation, specializes in crafting high-performance fibreglass grating for industrial walkways. Equipped with perfect testing equipment, strong technical support, and global export experience, ZJ Composites ensures their fibreglass grating and GRP mesh flooring meet international industrial standards, making them a trusted partner for wholesalers seeking reliable, long-lasting walkway solutions. This article explores why fibreglass grating is the top choice for industrial walkways, highlighting key benefits, application-specific advantages, and how ZJ Composites’ products elevate industrial safety and efficiency.

Core Advantages of Fibreglass Grating for Industrial Walkways

- Corrosion Resistance of Fibreglass Grating: Fibreglass grating’s greatest strength for industrial use is its exceptional resistance to corrosion—ZJ Composites’ grating is crafted from fiberglass strands embedded in a resin matrix (polyester or vinyl ester) that repels water, salt, chemicals, and humidity. In industrial environments like chemical plants or coastal refineries, where steel grating would rust within years, fibreglass grating retains its structural integrity for 20–30 years. Wholesalers can note that this resistance eliminates the need for costly anti-corrosion coatings (required for steel) and reduces the risk of walkway failure due to rust, ensuring long-term safety for industrial workers.

- Lightweight Design of GRP Mesh Flooring: GRP mesh flooring(a type of fibreglass grating) is 70% lighter than steel and 50% lighter than concrete, making it easy to transport, handle, and install in industrial settings—even in hard-to-reach areas like mezzanines or rooftop walkways. ZJ Composites’ fibreglass grating panels weigh just 8–12kg per square meter, so a 2-person team can install them without heavy equipment (like cranes), cutting installation time and labor costs by 40% compared to steel. This lightweight nature also reduces stress on industrial support structures (beams, joists), extending their lifespan and avoiding costly structural upgrades.

Safety Features of Fibreglass Grating for Industrial Walkways

- Non-Slip Surface of Fibreglass Grating: Industrial walkways often face oil, water, or chemical spills—so ZJ Composites’ fibreglass grating features a molded-in non-slip surface (textured resin or added grit) that meets OSHA safety standards. This texture retains grip even when wet or oily, reducing slip-and-fall accidents (a top industrial safety hazard) by 60% compared to smooth steel or concrete. For example, in a manufacturing plant with frequent oil spills, fibreglass grating walkways keep workers stable, minimizing downtime from injuries. Wholesalers can emphasize this safety feature to clients prioritizing worker well-being and compliance with industrial safety regulations.

- Non-Conductivity of GRP Mesh Flooring: GRP mesh flooring is non-conductive, making it ideal for industrial walkways near electrical equipment (e.g., power plants, electrical substations). Unlike steel grating (which conducts electricity and poses shock risks), fibreglass grating insulates against electrical current, protecting workers from accidental shocks. ZJ Composites’ grating is tested to withstand 10,000V, ensuring it meets strict electrical safety standards for industrial use. This feature is a must-have for wholesalers serving clients in electrical or energy sectors, where safety around live equipment is non-negotiable.

Fibreglass Grating for Different Industrial Walkway Scenarios

|

Industrial Scenario |

Key Challenge |

Ideal Fibreglass Grating Solution |

ZJ Composites Advantage |

|

Chemical Plants |

Chemical spills + corrosive fumes. |

Vinyl ester resin fibreglass grating + non-slip surface. |

Chemical-resistant resin + OSHA-compliant grip. |

|

Wastewater Treatment |

Moisture + biological corrosion. |

Polyester resin GRP mesh flooring + sealed edges. |

Moisture-resistant design + easy-to-clean surface. |

|

Manufacturing Plants |

Heavy equipment traffic + oil spills. |

Heavy-duty fibreglass grating (10mm thick) + grit texture. |

High load capacity (1,000kg/sq. m) + anti-slip grip. |

|

Power Substations |

Electrical conductivity + outdoor exposure. |

UV-stabilized GRP mesh flooring + non-conductive resin. |

10,000V insulation + UV resistance for outdoor use. |

Durability and Low Maintenance of Fibreglass Grating

- Impact Resistance of Fibreglass Grating: Industrial walkways face frequent impacts from equipment, tools, or heavy foot traffic—ZJ Composites’ fibreglass grating is reinforced with extra fiberglass strands in high-stress areas, making it resistant to cracking or breaking. Unlike brittle concrete or easily dented steel, fibreglass grating absorbs impacts without permanent damage, reducing the need for frequent repairs. For example, in a warehouse where forklifts occasionally bump walkway edges, fibreglass grating retains its shape, avoiding costly downtime for repairs.

- Low Maintenance of GRP Mesh Flooring: GRP mesh flooring requires minimal maintenance compared to traditional industrial walkway materials—no painting, rust removal, or wood treatment needed. ZJ Composites’ fibreglass grating only needs occasional cleaning with mild soap and water to remove debris or chemical residue, cutting annual maintenance costs by 70% compared to steel. Over a 20-year lifespan, this translates to significant savings: a fibreglass grating walkway costs 50% less to maintain than a steel equivalent, making it a cost-wise investment for industrial clients.

Fibreglass Grating FAQS

Can Fibreglass Grating Withstand Heavy Industrial Loads (e.g., Forklifts)?

Yes—ZJ Composites’ heavy-duty fibreglass grating (25–30mm thick) can withstand loads up to 1,000kg per square meter, enough for small forklifts, pallet jacks, or heavy equipment (with proper support spacing). The grating’s reinforced fiberglass strands distribute weight evenly, and the resin matrix adds impact resistance. Wholesalers can advise clients to specify support beam spacing (≤1.5 meters for heavy loads) to ensure optimal performance—ZJ Composites provides load-bearing charts to help match grating thickness to industrial load needs.

Is Fibreglass Grating Suitable for Outdoor Industrial Walkways?

Absolutely—ZJ Composites’ fibreglass grating for outdoor industrial walkways includes UV stabilizers in the resin matrix, preventing fading, brittleness, or degradation from sunlight. The grating also resists rain, snow, and temperature fluctuations (from -40°C to 120°C), making it ideal for outdoor walkways in refineries, construction sites, or power plants. Unlike wood, it won’t rot in wet conditions, and unlike steel, it won’t rust—ensuring year-round performance for outdoor industrial use.

How Does Fibreglass Grating Compare to Steel in Terms of Lifespan?

Fibreglass grating has a lifespan of 20–30 years in industrial environments, compared to 10–15 years for steel (even with anti-corrosion coatings). ZJ Composites’ rigorous testing (including UV resistance, chemical exposure, and impact tests) ensures their fibreglass grating retains 90% of its strength after 20 years. While steel may have a lower upfront cost, fibreglass grating’s longer lifespan and lower maintenance costs make it 30% more cost-effective over 20 years— a key point for wholesalers to highlight to budget-conscious industrial clients.

Can Fibreglass Grating Be Repaired If Damaged?

Yes—minor damage to fibreglass grating (e.g., small cracks or chips) can be repaired using resin-based repair kits (available through ZJ Composites). The kits include fiberglass mat, resin, and hardener—simply clean the damaged area, apply the mat and resin, and let it cure. For larger damage (e.g., a broken panel), ZJ Composites offers replacement panels that match existing grating, ensuring a seamless repair. Wholesalers can note that repairs are quick and cost-effective, avoiding the need to replace entire walkways (as often required with concrete or steel).

Where Can Wholesalers Source High-Quality Fibreglass Grating for Industrial Walkways?

Zhaojia Composites Co., Ltd (ZJ Composites) manufactures premium fibreglass grating and GRP mesh flooring for industrial walkways— all tested for durability, safety, and compliance with global industrial standards. With perfect testing equipment, strong technical support, and global export experience, ZJ Composites delivers customized solutions for diverse industrial needs.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025